Automatic garbage crushing device for environmental sanitation center

A garbage and sanitation technology, applied in the field of automatic garbage crushing devices, can solve the problems of easily damaged blades, reduce work efficiency, and low crushing efficiency, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

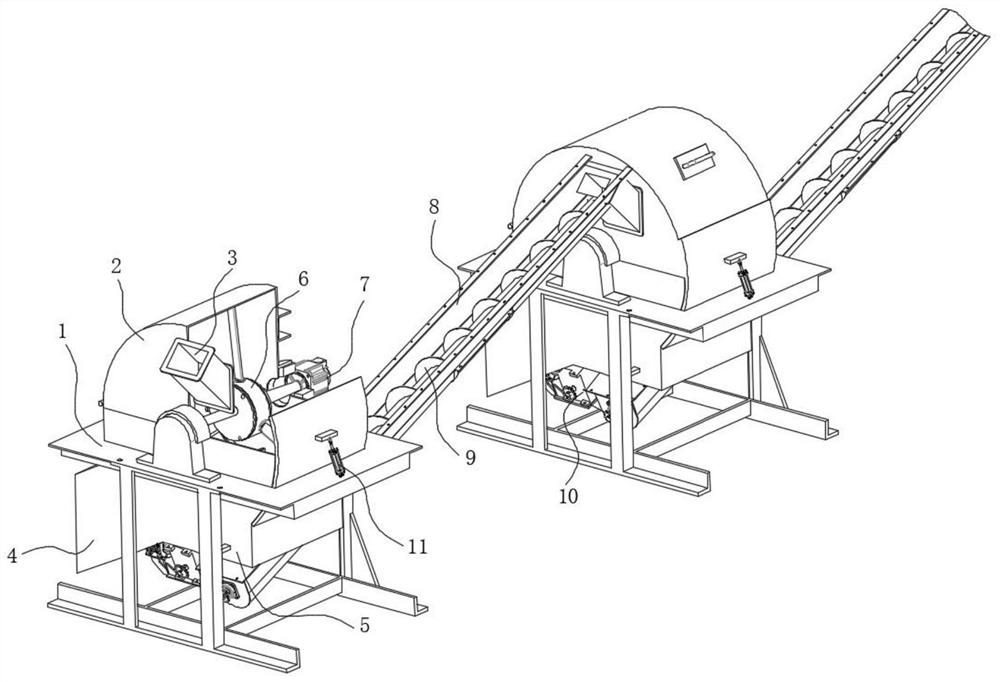

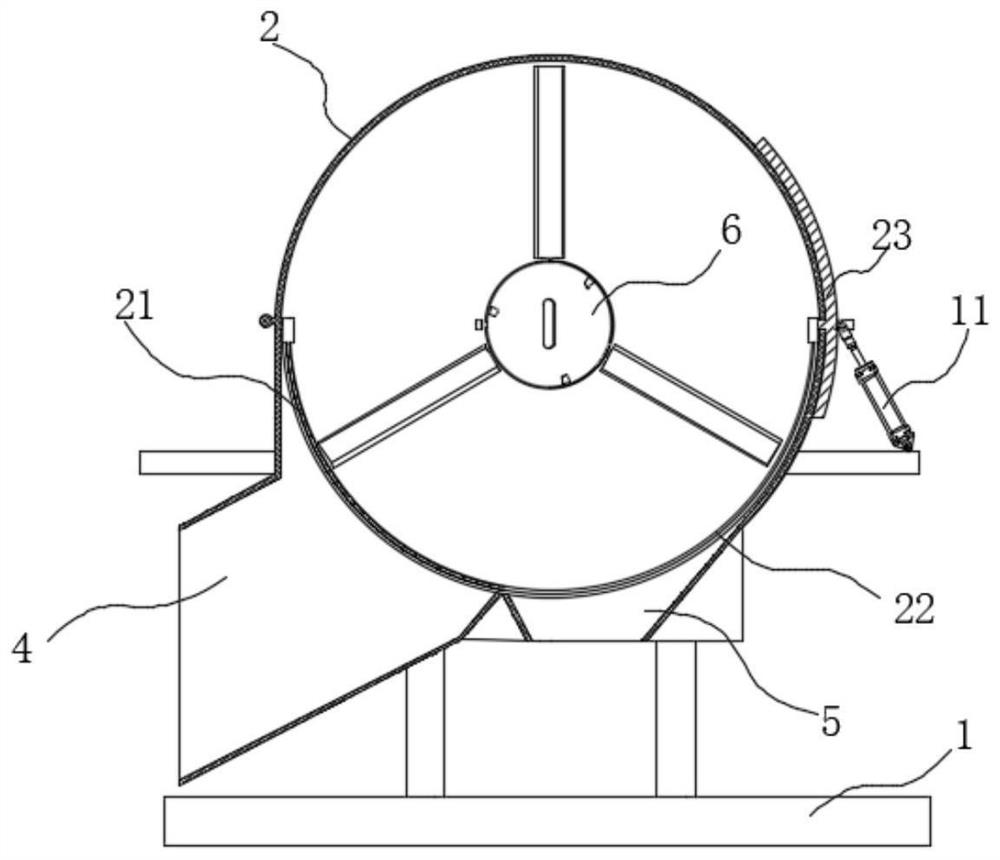

[0027] see figure 1 , in an embodiment of the present invention, an automatic garbage crushing device for a sanitation center, comprising a bracket 1, a plurality of the brackets 1 are arranged on the same straight line at a certain distance, and a crushing cylinder 2 is fixed in the bracket 1, and Each of the crushing cylinders 2 is coaxially distributed;

[0028] The upper side of the crushing cylinder 2 is provided with a feed port 3, the lower side is provided with a discharge port 4, and the other side is provided with a reprocessing port 5, and the outside of the reprocessing port 5 is connected with a transmission groove 8. The transmission The groove 8 is inclined upwards and is connected through the feed port 3 of the next adjacent crushing cylinder 2 .

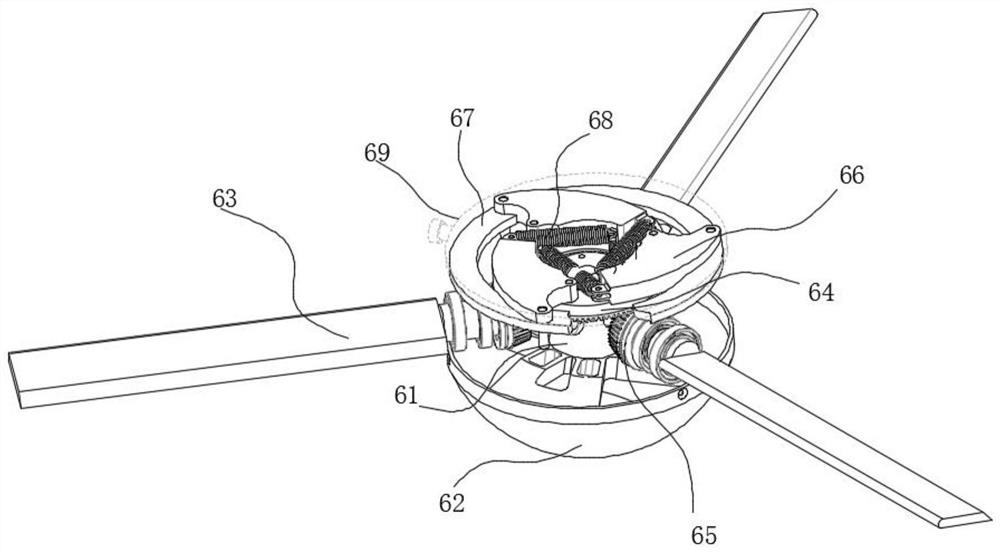

[0029] In this embodiment, each crushing cylinder 2 is rotatably provided with a crushing assembly 6, and the crushing assembly 6 includes a plurality of circumferentially distributed crushing blades 63, and a drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com