BTO intelligent correction device and method of full-automatic lead bonding machine

A technology of wire bonding machine and calibration method, which is applied to non-electric welding equipment, electrical components, circuits, etc., can solve the problems of manual operation and measurement workload, easy to make mistakes, etc., to achieve high calibration efficiency and reliability, and fast calibration speed. , The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now in conjunction with accompanying drawing, the present invention will be further described:

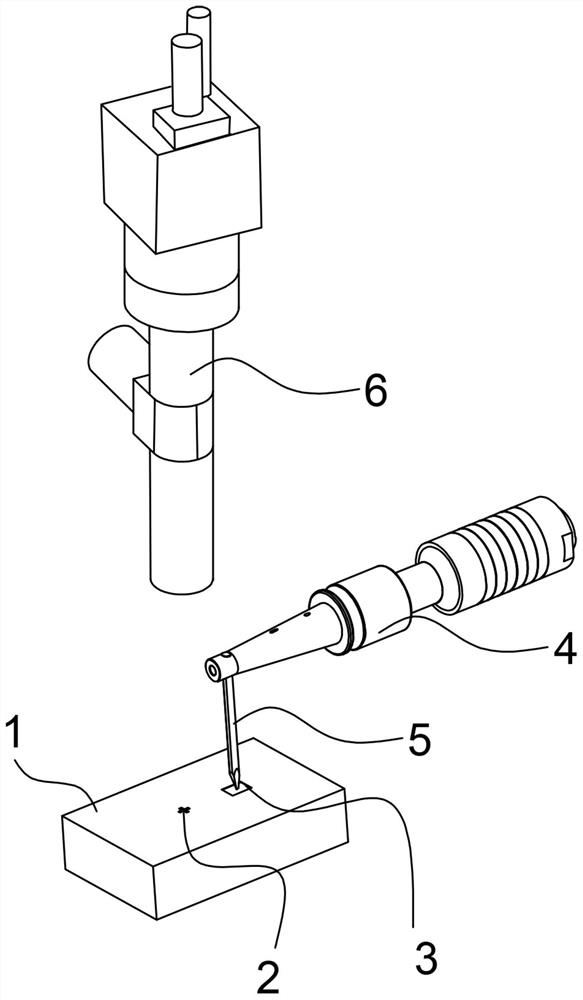

[0032] refer to figure 1 , a BTO intelligent correction device of a fully automatic wire bonding machine described in this embodiment, the fully automatic wire bonding machine includes a workbench 1 for carrying chip workpieces, a bonding head 4 provided with a chopper 5 and imaging optical system 6 .

[0033] The BTO intelligent correction device includes:

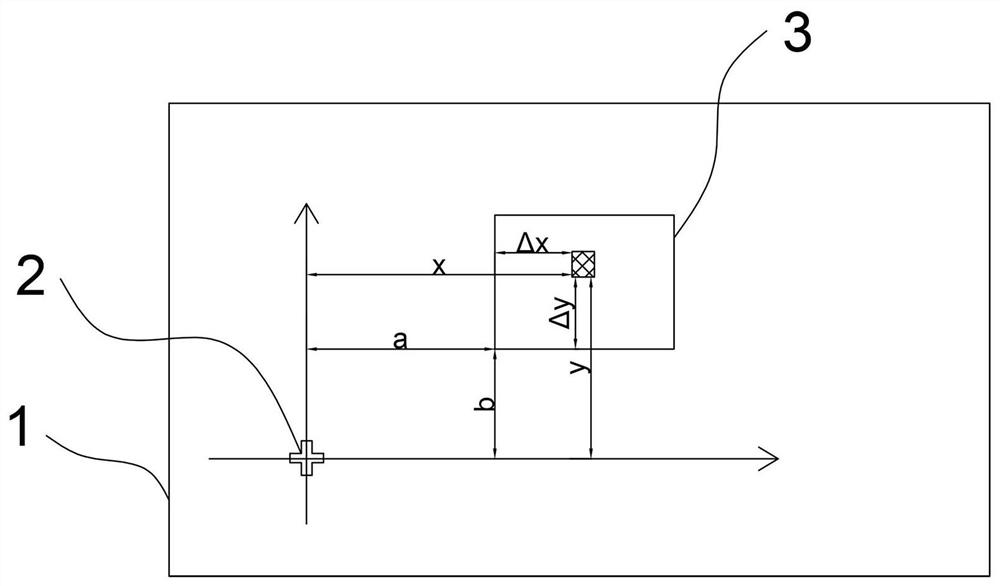

[0034] The basic mark point 2 is set on the workbench 1 for alignment and recognition by the imaging optical system 6 as the origin of the plane coordinate system;

[0035] The detector 3 is arranged on the workbench 1 at a theoretical BTO position away from the basic marking point 2, and is used to detect the distance between it and the riving knife 5 and generate an electrical signal by induction when the riving knife 5 moves to the adjacent position above the detector 3;

[0036] The difference correction system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com