Pipeline welding opening supporting equipment

A technology for supporting equipment and welding joints, which is applied in the field of supporting equipment for pipeline welding joints, which can solve problems such as disconnection, dislocation of welding points of steel pipes, rolling of steel pipes, etc., and achieve the effects of ensuring heat dissipation, improving air circulation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

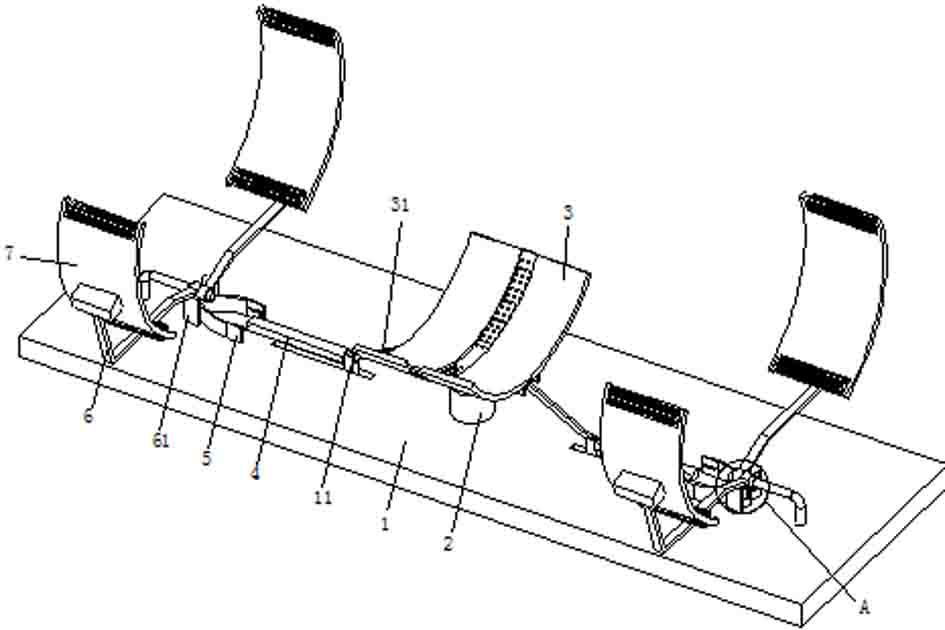

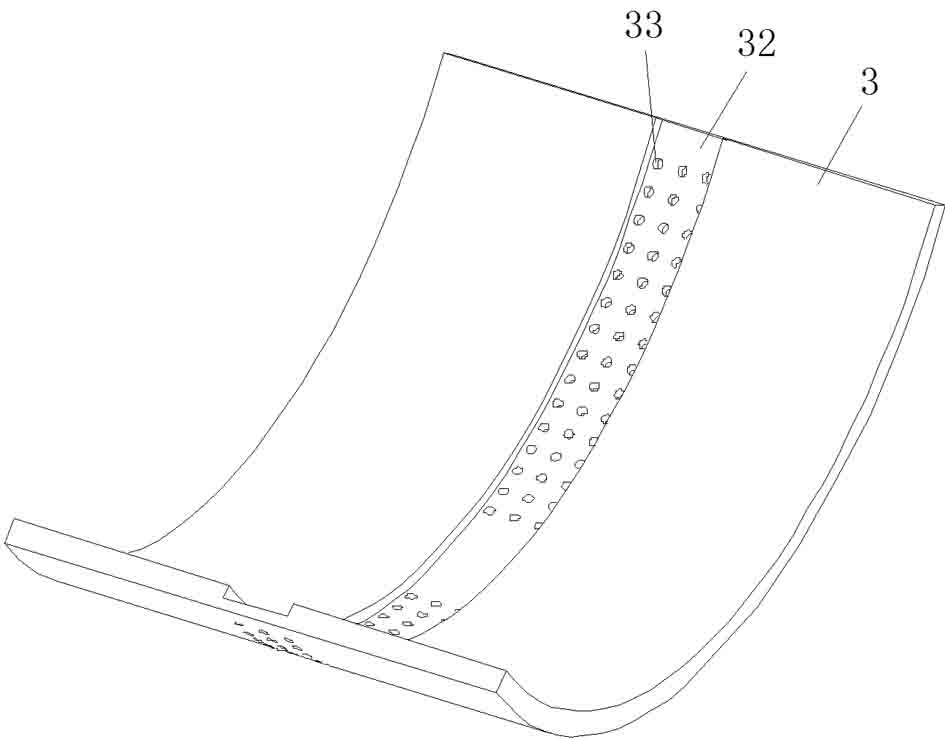

[0031] see Figure 1-2 , the present invention provides a technical solution: a pipe welding port support equipment, including a bottom plate 1 placed, the top center of the bottom plate 1 is connected to the center of the bottom of the support arc plate 3 through an elastic telescopic support column 2, and the support arc plate 3 is two The side bottoms are respectively hinged with two hinged transmission rods 31 at one end, and the other end of the hinged transmission rods 31 is hinged with the top of the slide block 11. One end of the push column 4 is fixed, and the other end of the push column 4 is installed on one side of the control spreader frame 5, and the other side of the control spreader frame 5 is in contact with the adjacent side of the two matching bars 61, and the side of the tie bar 61 near the control spreader frame 5 is Convex arc-shaped surface, and the contact part of the control spreader frame 5 and the matching strip 61 is also arranged on the convex arc-...

Embodiment 2

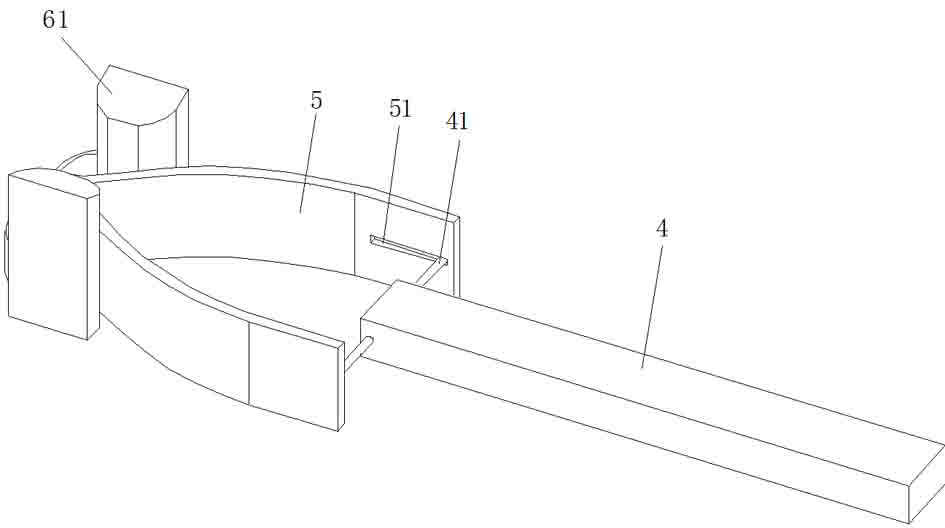

[0035] see figure 1 , image 3 , Figure 4 and Figure 5 , on the basis of Embodiment 1, in this embodiment, the control spreader frame 5 is in a "V" shape, the push column 4 is located between the two endpoints on the same side of the control spreader frame 5, and the front and rear sides of the push column 4 Both sides are fixed with sliding rod 41, and sliding rod 41 is slidingly connected with the chute 51 that is opened on the inside of control stretching frame 5, and the straight part is arranged on control stretching frame 5, and the straight part of control stretching frame 5 is positioned at the control stretching frame. 5 at the two endpoints on the same side, the chute 51 is set on the inner side of the straight part of the control spreader 5 and the length is less than the length of the straight part of the control spreader 5, and the center of the side where the matching strip 61 contacts the control spreader 5 is also A straight part is provided; by setting th...

Embodiment 3

[0038] see figure 1 , Figure 6 and Figure 7 , on the basis of Embodiment 1, in this embodiment, positioning rollers 8 are mounted on both ends of the wrapping positioning arc plate 7 for rotation, the positioning rollers 8 are made of rubber, and the surface of the positioning rollers 8 has a plurality of resistance increasing concave Groove 81, increasing resistance groove 81 comprises an arc portion and a straight portion, and the arc portion in the resistance increasing groove 81 between two parcel positioning arc plates 7 is positioned at the bottom of the straight portion; The roller 8 can position the steel pipe, and when the steel pipe rotates, the rotation of the positioning roller 8 will reduce the resistance when the steel pipe rotates. At the same time, setting the resistance increasing groove 81 can increase the friction between the positioning roller 8 and the outer wall of the steel pipe. , to ensure that the positioning roller 8 will rotate when the steel pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com