Forming injection mold and injection molding method thereof

An injection mold and mold technology, applied in the field of molding injection molds and injection molding, can solve the problems of clogging the mouth of the nozzle, unable to ensure the uniform distribution of liquid, and accelerate the cooling of liquid, so as to avoid the operation of pushing and discharging, avoid The effect of uneven distribution of injection liquid and reduction of secondary operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

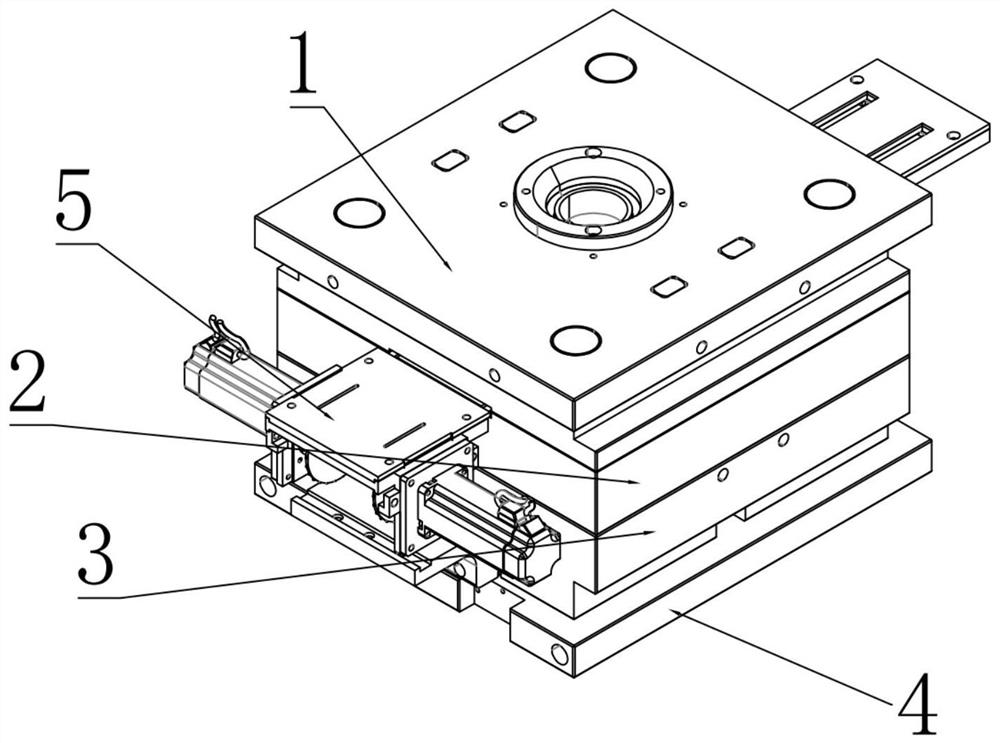

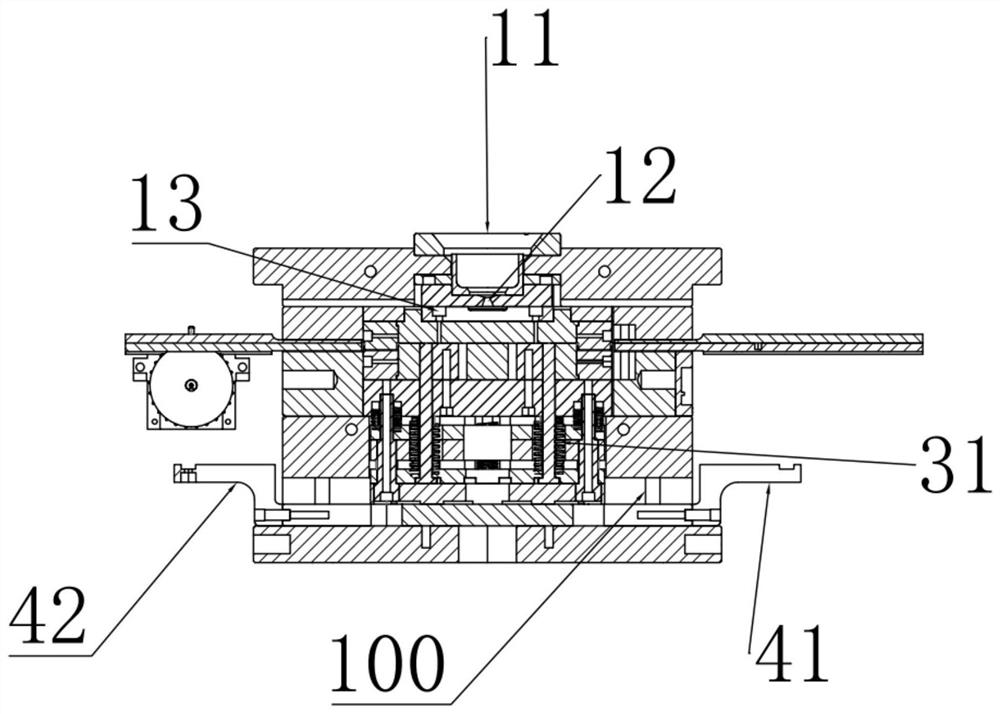

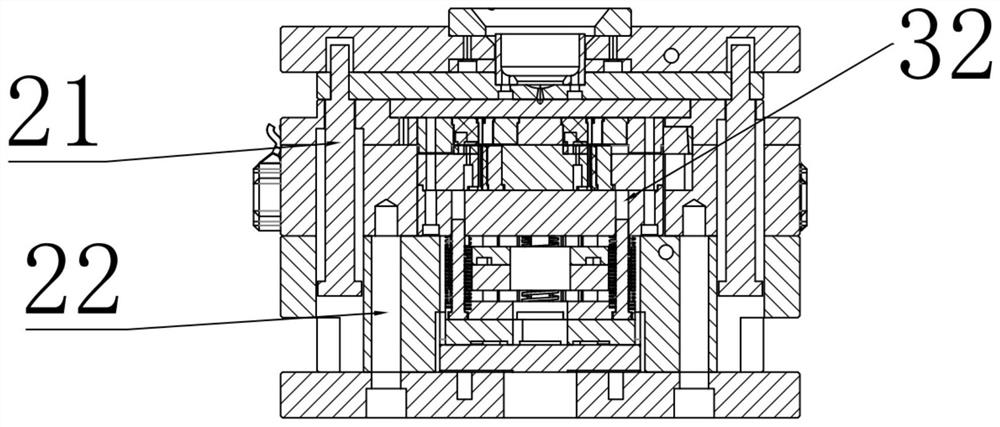

[0029] A molding injection mold, comprising: an injection plate 1, an upper mold 2, a lower mold 3, a bottom plate 4, a driving assembly 5, a liquid injection hole 11, a nozzle opening 12, a through hole 13, a limit pin 21, a limit groove 22, Spring 31 , spring support 32 , second fixed block 41 , first fixed block 42 , first motor 51 , pin shaft 100 , mold ejection bracket 110 .

[0030] Injection template 1, the upper mold 2 that is arranged on described injection template 1 below, the lower mold 3 that is arranged on described upper mold 2 below; The bottom plate 4 that is arranged on described lower mold 3; And is arranged on described injection template 1 and The driving assembly 5 at the matching place of the upper mold 2; the injection plate 1, the upper mold 2 and the lower mold 3 are fixed by a limit pin 21; and the limit pin 21 can move up and down; avoid mold injection There is a positional shift.

[0031] The injection plate 1 includes a liquid injection hole 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com