A ship bollard with pull force detection function

A tension detection and mooring technology, which is applied in the field of ship outfitting, can solve problems such as no warning, easy cable breakage, and inability to achieve the effect of improving functionality, reducing cable breakage, and reducing roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

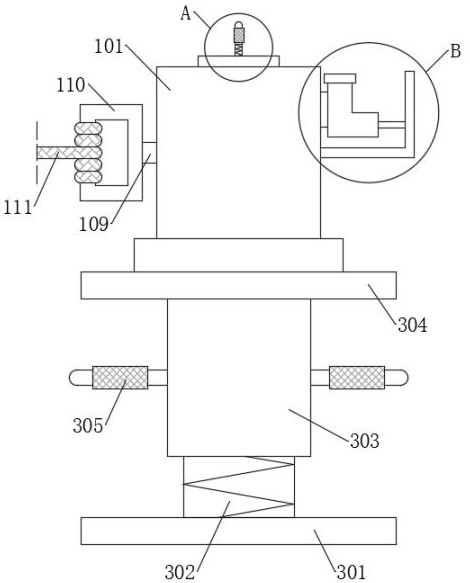

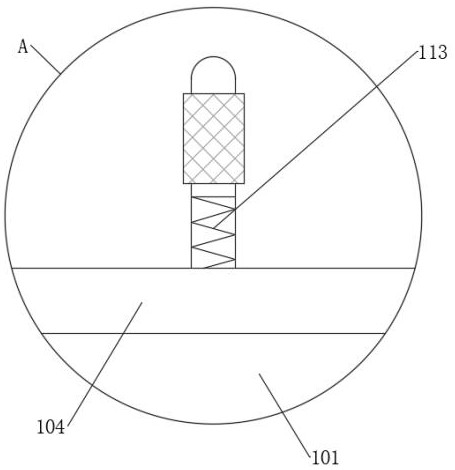

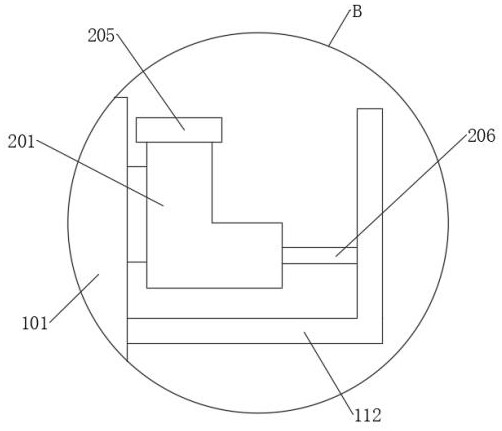

[0046] see Figure 1-10 , a ship mooring bollard with a tension detection function, comprising a pile body 101 and an adjustment auxiliary inspection base, the inside of the pile body 101 is provided with a built-in adjustment groove 103, and the top of the pile body 101 is embedded with a pressure adjustment box 104, the pressure adjustment The box 104 runs through the outer wall of the built-in regulating tank 103 and extends into the built-in regulating tank 103. The outer wall of the bottom end of the pressure regulating box 104 slides through and is provided with a rough anti-slip plate 105, and the pressure regulating box 104 is provided with a matching piston. Two pressure supply springs 107 are fixedly connected between the piston plate 106 and the rough resistance slide plate 106, the pressure supply springs 107 are in a compressed state, and a detection rod 108 is arranged in the built-in adjustment groove 103, and the top of the detection rod 108 is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com