Stretchable, compressible and antifreeze organohydrogel electrolyte, preparation method and application

A hydrogel and electrolyte technology, applied in the field of compressible, antifreeze organic hydrogel electrolyte, and stretchable, can solve the problems of low temperature performance compression performance, etc., and achieve significant resistance change, good reversibility, good low temperature electricity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

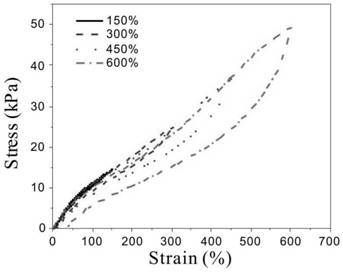

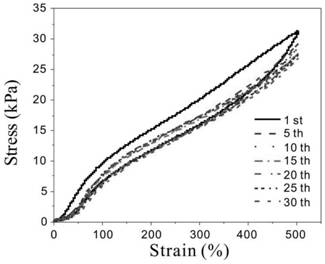

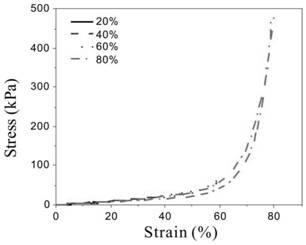

[0062] A stretchable, compressible, and freeze-resistant organohydrogel electrolyte S 1 A 4 and preparation method thereof, hydrogel electrolyte S 1 A 4 Include the following components by mass fraction:

[0063] Soy protein isolate 2.0%, SBMA 2.7%, AAm 10.9%, MBA 0.027%, lithium chloride 6.55%, ammonium persulfate 0.027%, the balance is DMSO and water, and the mass ratio of DMSO and water is 3:7. S 1 A 4 The mechanical and electrical properties of the hydrogels are shown in Table 1.

[0064] Hydrogel Electrolyte S 1 A 4 The preparation method comprises the following steps:

[0065] a. Add 0.225g of soybean protein isolate, 2.55g of DMSO and 5.95g of water into a 20mL glass bottle, and place the glass bottle in a 90°C constant temperature water bath and stir for 2h;

[0066] b. Add SBMA and acrylamide in a mass ratio of 1:4 (total amount is 1.5g) into a glass bottle, then add 0.003g MBA, 0.72g lithium chloride, 0.0225g ammonium persulfate, and stir magnetically for 30...

Embodiment 2

[0069] A stretchable, compressible, and freeze-resistant organohydrogel electrolyte S 1 A 1 and preparation method thereof, hydrogel electrolyte S 1 A 1 , including the following components by mass fraction:

[0070] Soy protein isolate 2.0%, SBMA 6.8%, AAm 6.8%, MBA 0.027%, lithium chloride 6.55%, ammonium persulfate 0.027%, the balance is DMSO and water, and the mass ratio of DMSO and water is 3:7. S 1 A 1 The mechanical and electrical properties of the hydrogels are shown in Table 1.

[0071] Hydrogel Electrolyte S 1 A 1 The preparation method is the same as in Example 1, except that the mass ratio of SBMA to AAm is 1:1.

Embodiment 3

[0073] A stretchable, compressible, and freeze-resistant organohydrogel electrolyte S 1 A 8 and preparation method thereof, hydrogel electrolyte S 1 A 8 , including the following components by mass fraction:

[0074] Soy protein isolate 2.0%, SBMA 1.52%, AAm 12.1%, MBA 0.027%, lithium chloride 6.55%, ammonium persulfate 0.027%, the balance is DMSO and water, and the mass ratio of DMSO and water is 3:7. S 1 A 8 The mechanical and electrical properties of the hydrogels are shown in Table 1.

[0075] Hydrogel Electrolyte S 1 A 8 The preparation method is the same as that in Example 1, except that the mass ratio of SBMA to AAm is 1:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com