Diaphragm type gas meter

A membrane gas meter and crank gear technology, which is applied to measuring devices, instruments, liquid/fluid solid measurement, etc., can solve the problems of crank gear skew, affecting gas meters, etc., and achieves reduced running resistance, easy assembly, and improved operation. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

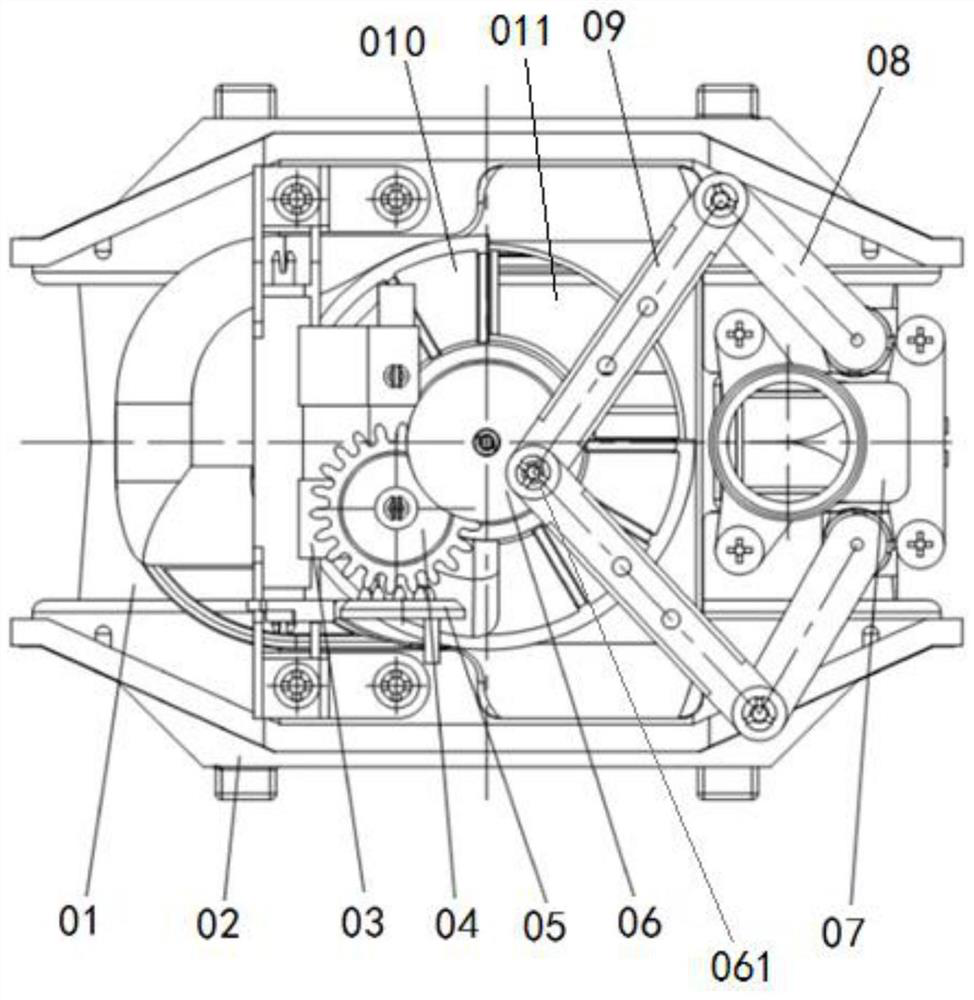

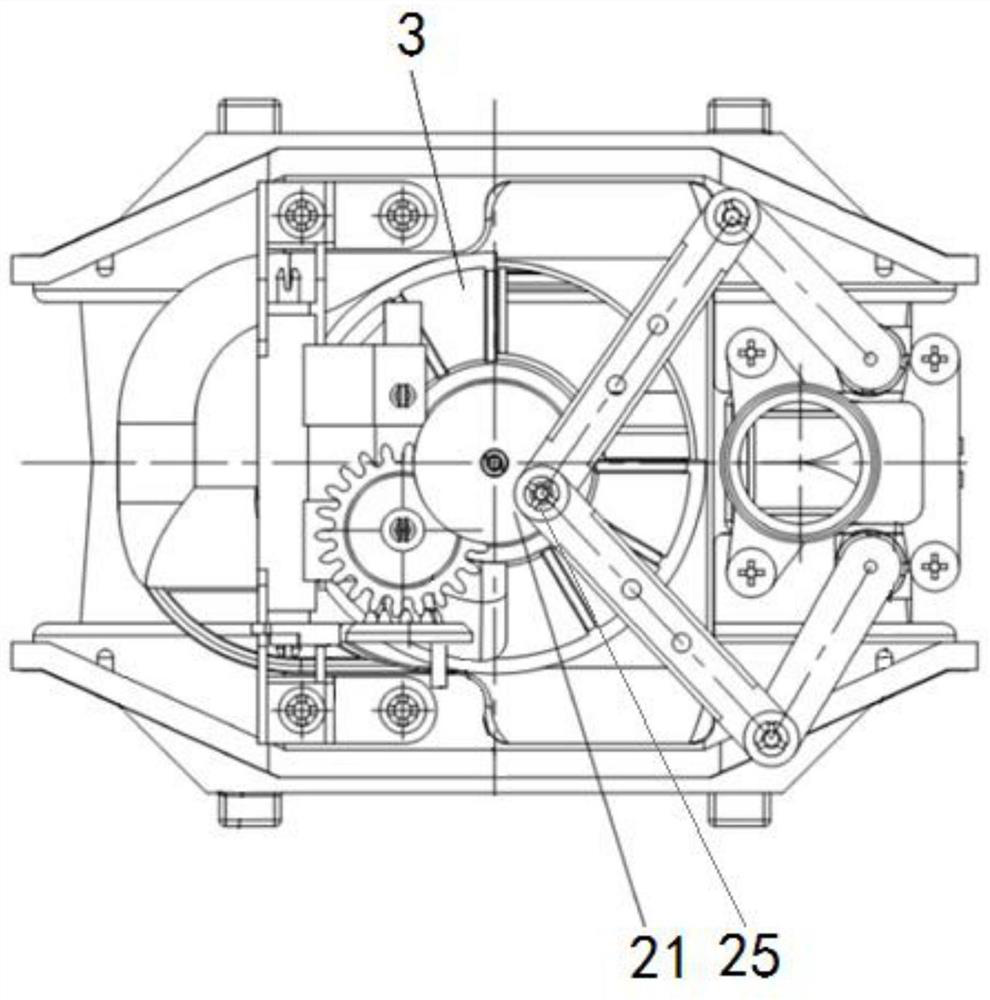

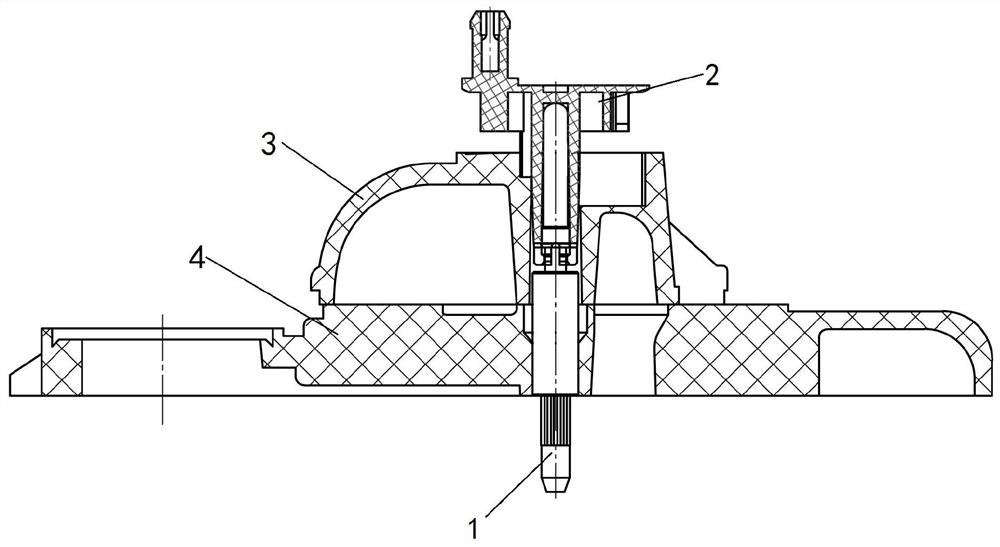

[0027] Such as Figure 2-6 As shown, the diaphragm gas meter includes a central shaft 1 and a crank gear structure 2; the crank gear structure 2 includes a crank gear 21, a crank gear shaft 22, and a crank shaft 25, and the crank gear shaft 22 is formed at the bottom end of the crank gear 21. , the crankshaft 25 is eccentrically and fixedly arranged above the crank gear 21, and the center of the crank gear shaft 22 is provided with a central shaft hole with an opening downward; the central shaft hole includes a first assembly hole section 231, a transition hole section, 232 and the second assembly hole section 233, the diameter of the first assembly hole section 231 is smaller than the diameter of the second assembly h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap