Optical cable connector with good waterproofness

An optical cable connector, waterproof technology, applied in the direction of light guide, optics, instruments, etc., can solve the problems of loose plugs and sockets, poor sealing effect, repeated debugging by installers, etc., to avoid the intrusion of external water vapor, avoid plugging The effect of poor connection and good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

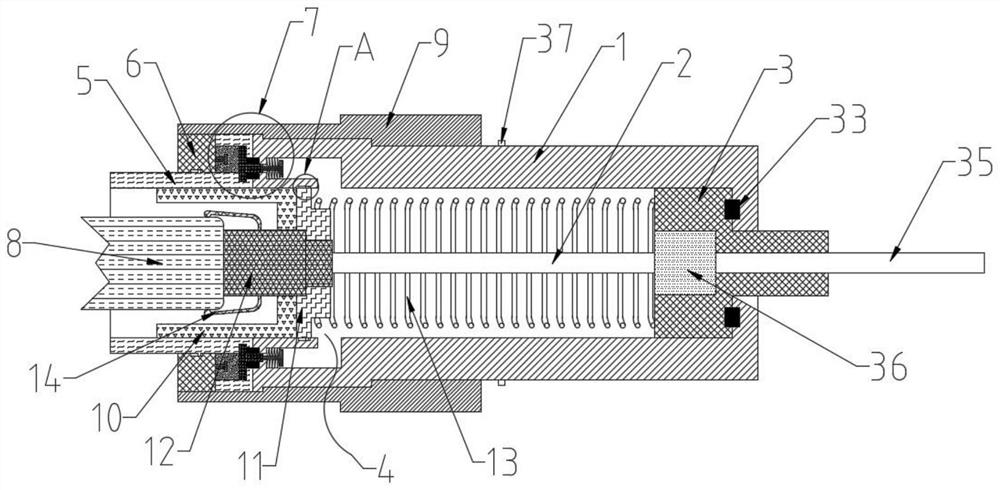

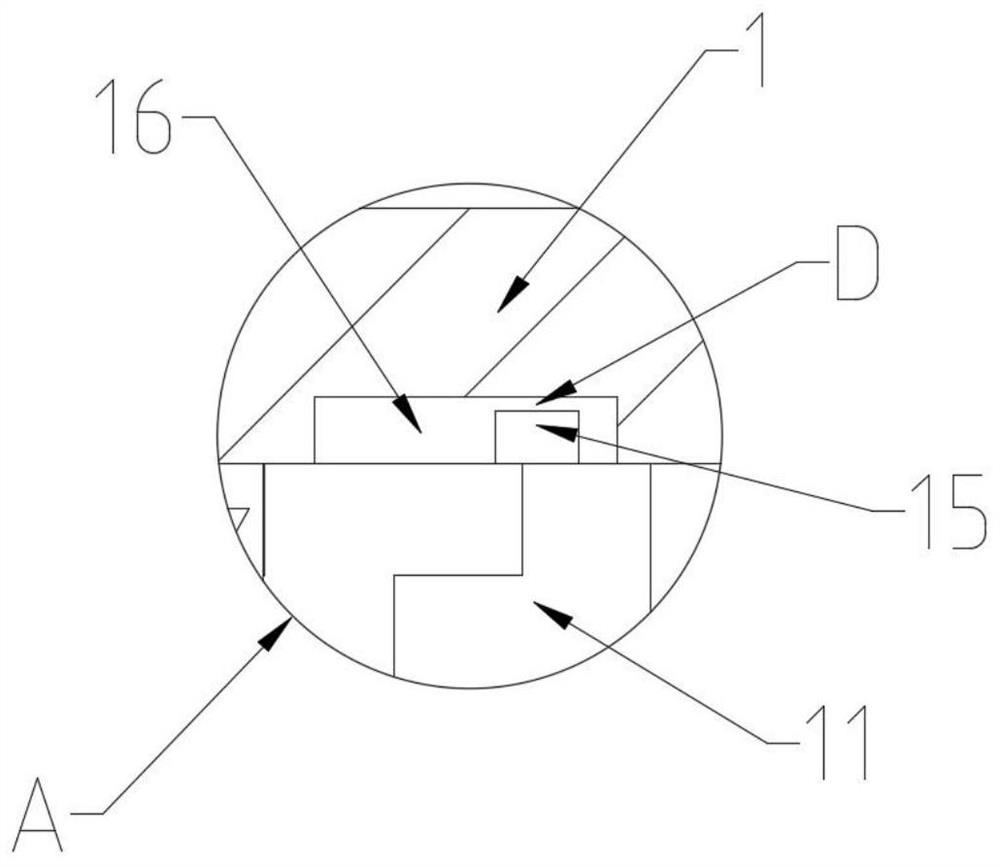

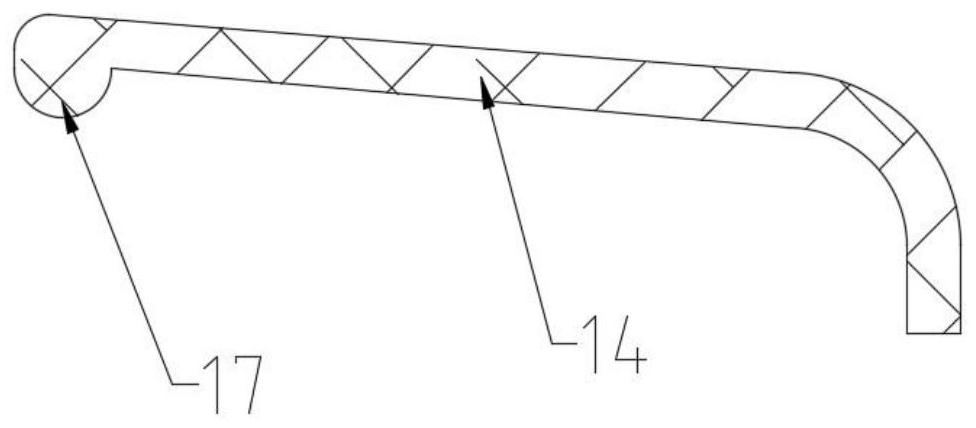

[0031] Embodiment: the present invention provides technical scheme, as figure 1 , a fiber optic cable connector with good water resistance, including a sleeve body 1, the sleeve body 1 is a hollow cylindrical structure, used to protect the indoor optical cable 2 and seal it with the fixed socket housing 5 at the same time, the sleeve body 1 is close to the optical cable One end of the guide head 3 is a shut-off structure. The sleeve body 1 is provided with an indoor optical cable 2. The indoor optical cable 2 is a section of optical cable located in the sleeve body 1. Through the mating of the elastic plug mechanism 4 and the socket 8, the indoor optical cable can be connected. 2 is connected to the optical cable at the end of the socket 8. An optical cable guide 3 is provided at one end of the sleeve body 1. The optical cable guide 3 is a hollow structure. 3 parts are blocked in the sleeve body 1, and the other part passes out of the sleeve body 1. The other end of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com