Pull-out type rapid control electric cabinet device

A rapid control and pull-out technology, applied in pull-out switchgear, substation/distribution device housing, switchgear, etc., can solve the problems of complex control part of non-standard equipment, cumbersome installation process, and long laying distance of lines , to achieve the effect of convenient strong current control and air source control, convenient later maintenance, and reducing interference and attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

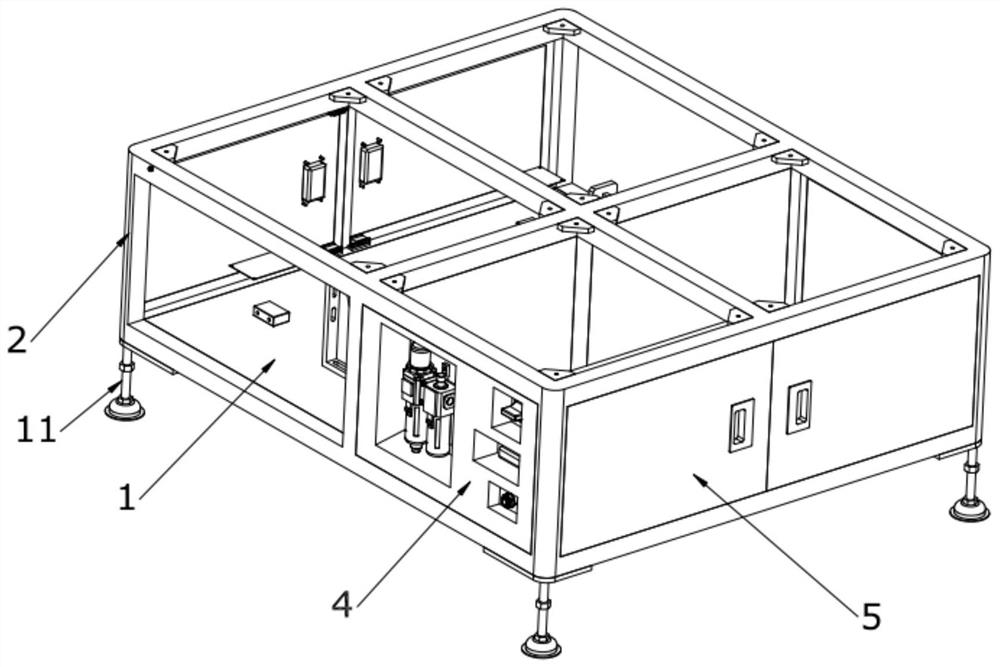

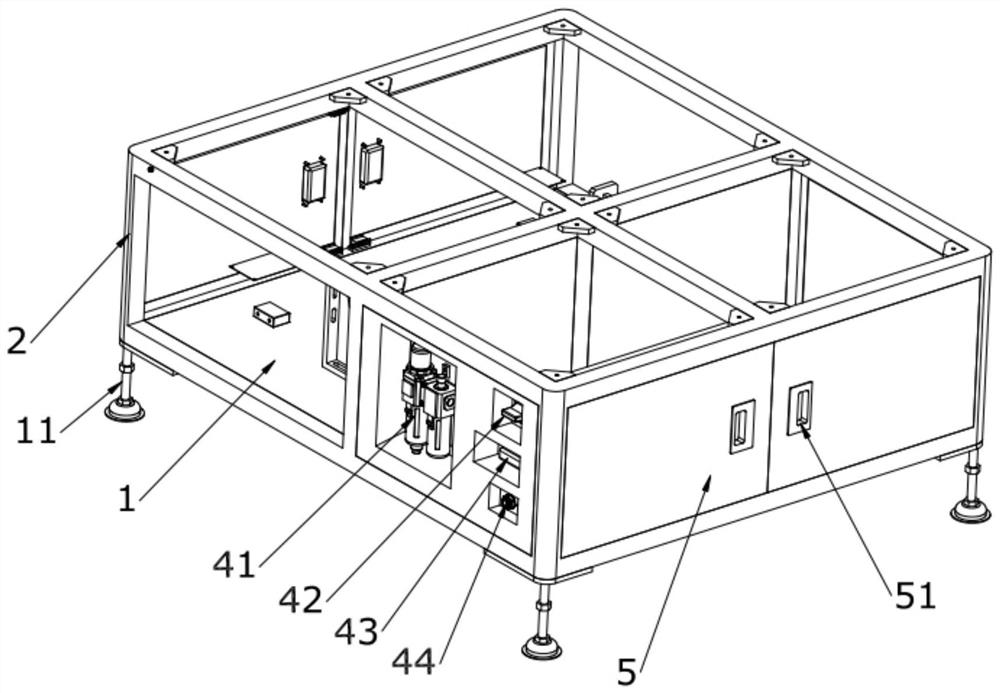

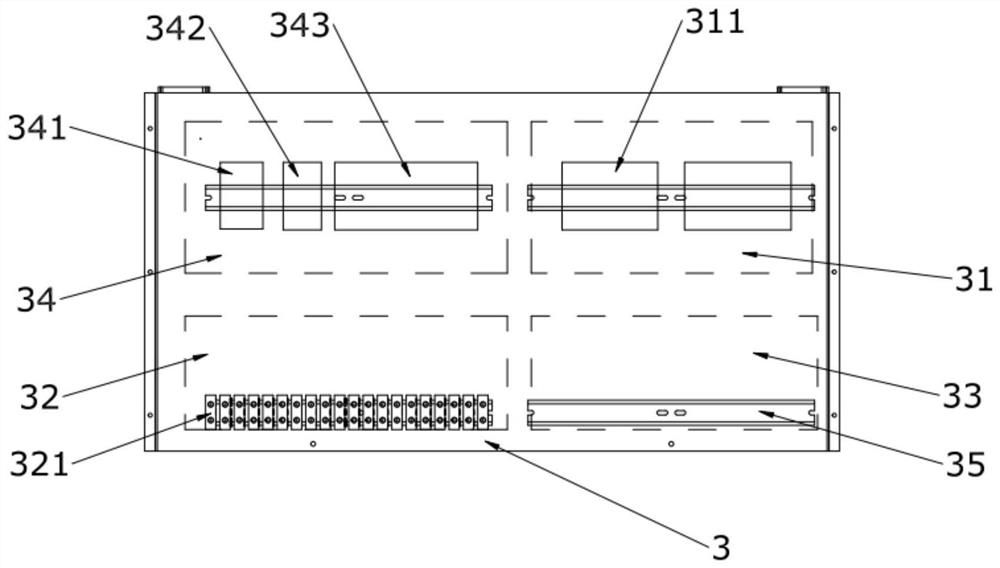

Embodiment example 1

[0047] A pull-type fast control electric cabinet device, including a base, a support frame and an electric control floor, the support frame is fixedly connected to the base, the support frame is a frame structure, and support feet are installed at the bottom of the base, The electric control base plate is used for accommodating the control circuit, and the base is provided with slide rails, and the electric control base plate is slidably connected with the base through the slide rails. The electric control baseboard is provided with a strong current area and a weak current area, the weak current area is provided with connecting terminals, and the strong current area is provided with a servo driver. The electric control base plate is provided with a control area, and the control area is provided with a protection circuit and a PLC controller. The protection circuit is provided with an air switch and a fuse. By providing an air switch and a fuse, electrical safety accidents cau...

Embodiment example 2

[0049] The control electric cabinet device is a horizontal control electric cabinet device, the support frame includes three groups, each group of support frames includes three support rods, and the three groups of support frames are relatively arranged on the base. A support beam is connected above the support bar, and the support beams are vertical in pairs. The support bar and the support beam form a frame structure, and an operation platform is installed on the operation support beam. The rest of the structure is as in the implementation case 1.

Embodiment example 3

[0051] The control electric cabinet device is a vertical control electric cabinet device. The rest of the structure is as in the implementation case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com