Garment structure and manufacturing method thereof

A clothing and clothing technology, applied in the field of clothing structure and its manufacturing, can solve the problems of high cost, insufficient flexibility, and complicated process, and achieve the effect of strong three-dimensional effect, simple structure, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

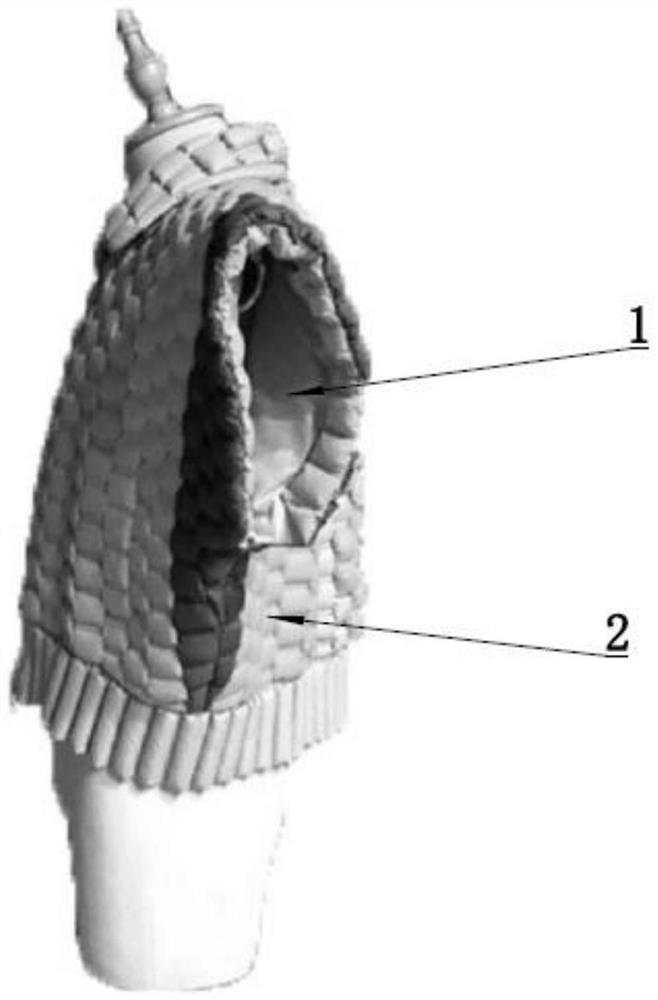

[0036] Such as Figure 1-4 Shown, a kind of clothing structure, comprises: clothing main body 1; And

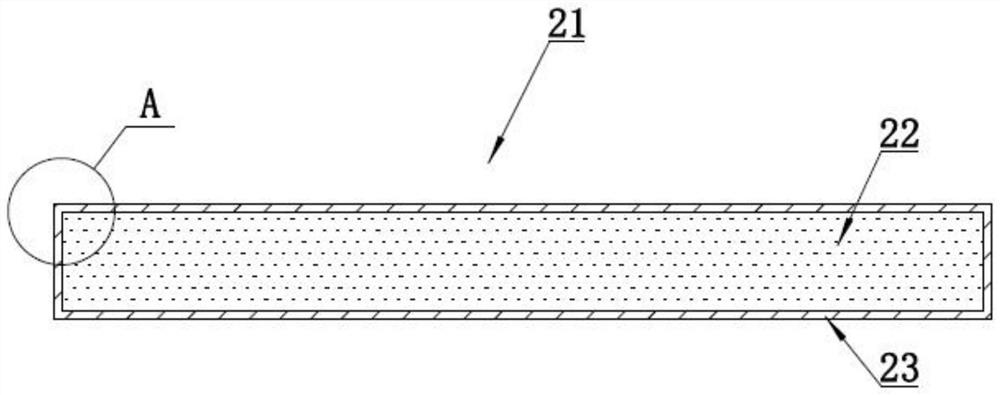

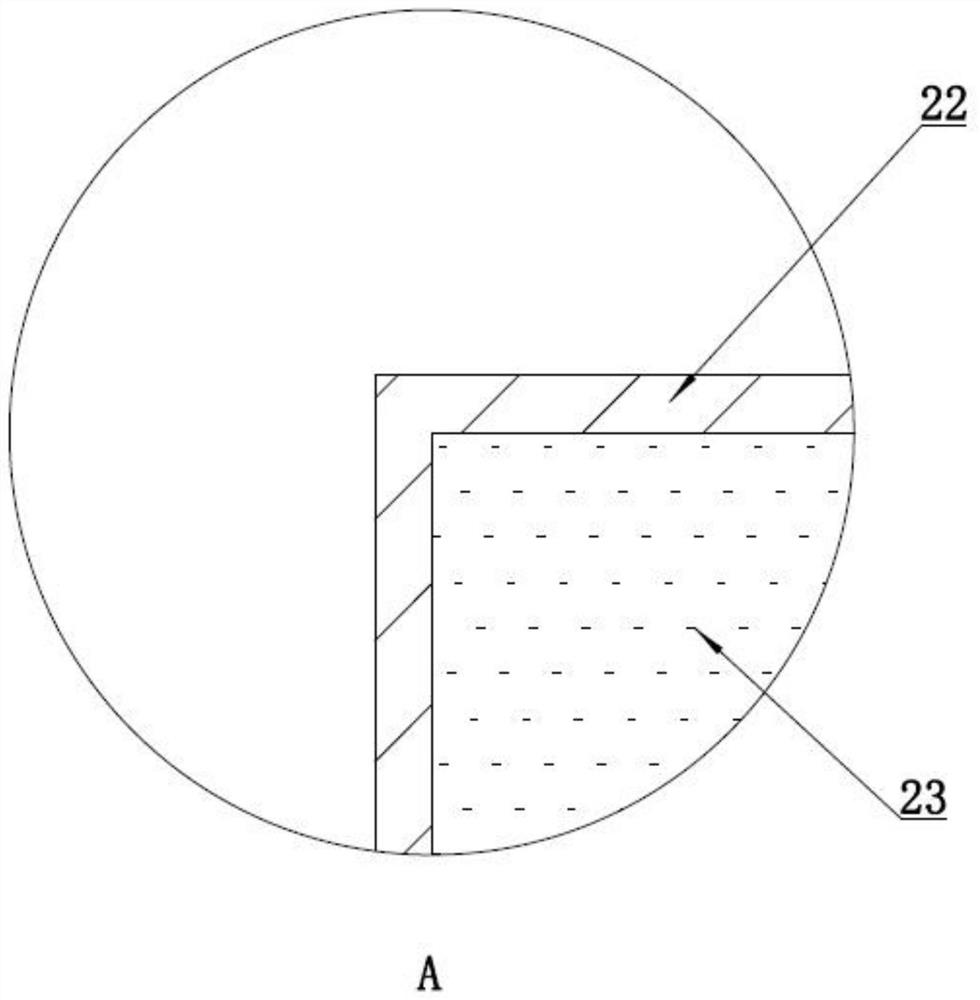

[0037] The three-dimensional structure 2 is arranged on the outer surface of the clothing main body 1. The inner surface of the clothing main body 1 refers to the side in contact with the human body. The outer surface of the clothing main body 1 is far away from the inner surface of the clothing main body 1, and at least includes a deformable The flexible member 21 is configured, and the flexible member 21 includes an outer layer 22 and an inner cavity 23, that is, the outer layer 22 wraps the inner cavity 23, and the inner cavity 23 is specially opened inside the outer layer 22 along the length direction of the flexible member 21 and Filling is provided, such as cotton, down or other soft fillers, the present invention is not limited, the flexible member 21 can be divided into at least one flexible unit 24, and the flexible unit 24 is configured to form connecting sections w...

no. 2 example

[0044] Such as Figure 9 Shown, a kind of garment structure manufacturing method comprises the following steps:

[0045] S1: affixing the first fixed section 26 of the flexible unit 24 to the main body of the garment 1;

[0046] S2: approach the second fixed section 27 of the flexible unit 24 towards the first fixed section 26, so that the distance between the first fixed section 26 and the second fixed section 27 is less than the length of the connecting section 25;

[0047] S3: affixing the second fixing section 27 of the flexible unit 24 to the main body of the garment 1;

[0048] S4: fixing other flexible units 24 of the flexible member 21 in sequence according to a predetermined path.

[0049] It should be noted that the above-mentioned steps are all descriptions for the same specified flexible part 21 , and the operation steps of other flexible parts 21 are similar to this and will not be repeated here.

[0050] In this embodiment, the affixation of the first fixed sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com