Injection-molded product demolding mechanism of injection molding machine

A technology of injection molding products and demoulding mechanism, applied in the field of product processing, can solve problems such as easy slipping of products, and achieve the effect of not easy to fall and stable clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

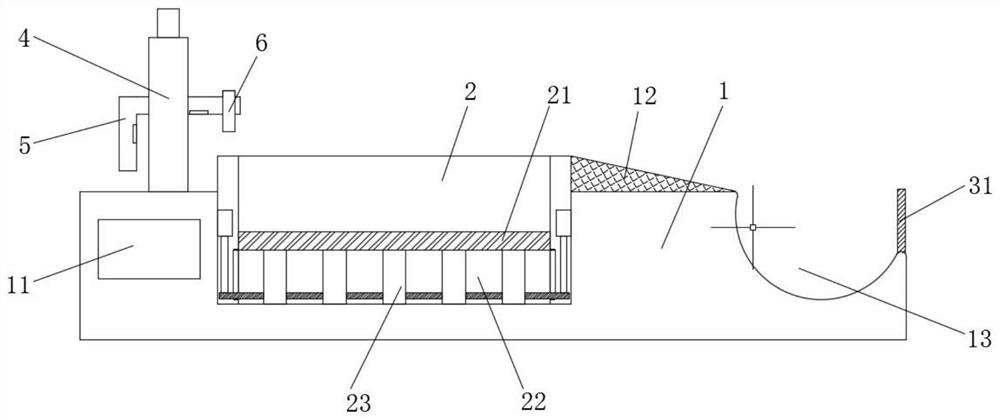

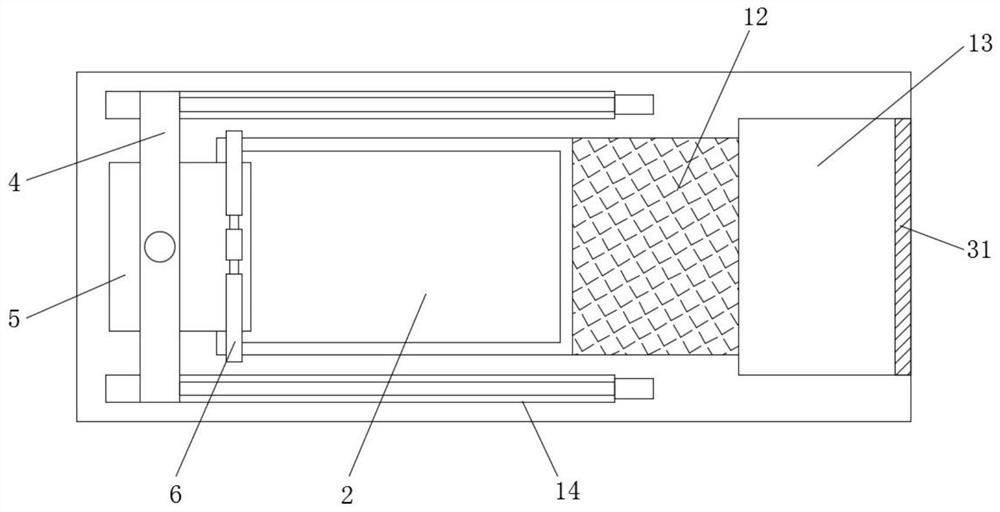

[0028] After the molding is completed, start the second linear motor to drive the connecting rod to move up, thereby driving the ejector rod 23 to lift the product upwards. After the jacking, the first linear motor is started to drive the fixed frame 4 along the figure 2 The guide groove 14 in the middle slides to the right. At the same time, during the movement, start the first lifting motor to make the adjustment plate 5 move down. When the vertical part of 5 is in contact with the product, start the first lifting motor again, so that the adjustment plate 5 continues to move down to contact with it, and then the electric suction cup is activated to suck the product, and then the first lifting motor drives the adjustment plate 5 And the product moves upwards synchronously. During the upward movement, the second lifting motor starts to drive the lifting seat 7 to move upwards, so that the connecting handle 71 drives the sliding bolt to slide in the adjusting hole 62, so that t...

Embodiment 2

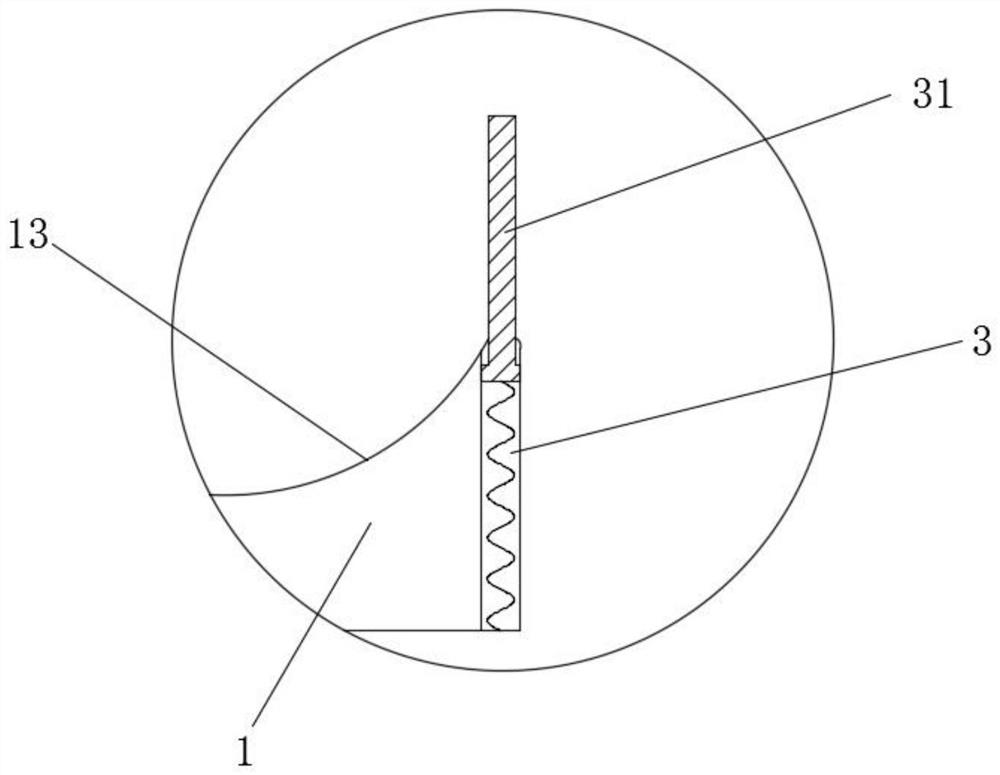

[0029] Embodiment 2: In this embodiment, on the basis of Embodiment 1, the spring board 31 and the receiving trough 13 can be directly integrated, and the height of the spring board 31 can be set as required.

Embodiment 3

[0030] Embodiment 3: In this embodiment, on the basis of Embodiment 1, the bottom plate 21 can be directly set to be movable, but it is seamlessly connected with the inner wall of the bottom mold 2, and under the bottom plate 21 An electric cylinder is provided, so that the lifting of the product can be realized directly by raising the bottom plate 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com