Flush car door structure

A technology for car doors and car door glass, which is applied to doors, car parts, windows, etc. It can solve the problems of uneven transition between car door glass and car door trim panels, poor sealing performance, and increased wind resistance, achieving a clean and simple appearance, low cost, and The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

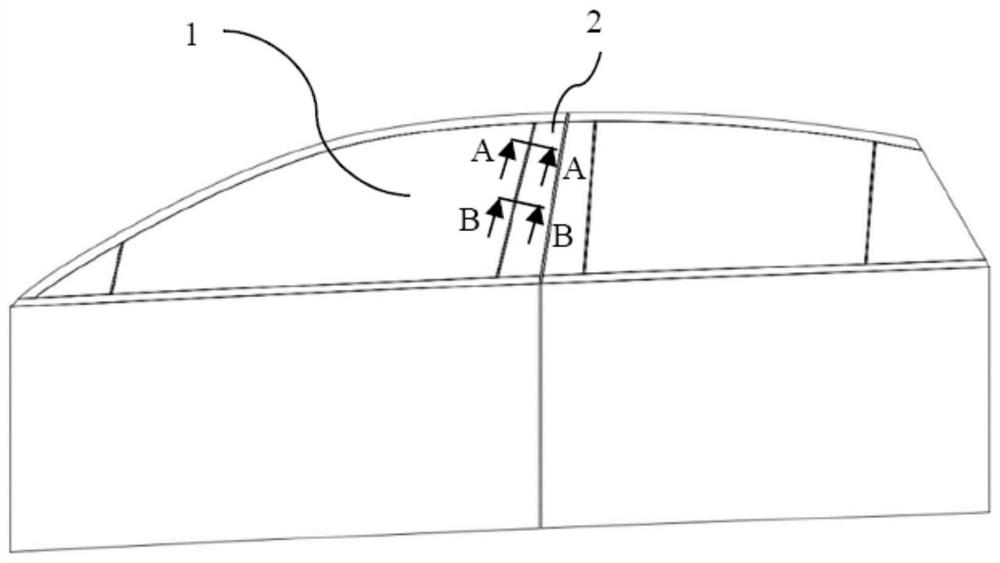

[0020] Such as figure 1 As shown, a flush door structure includes the door glass 1, the door trim 2 and the side appearance of the entire door, as well as the position of the door pillar area (section A-A, B-B).

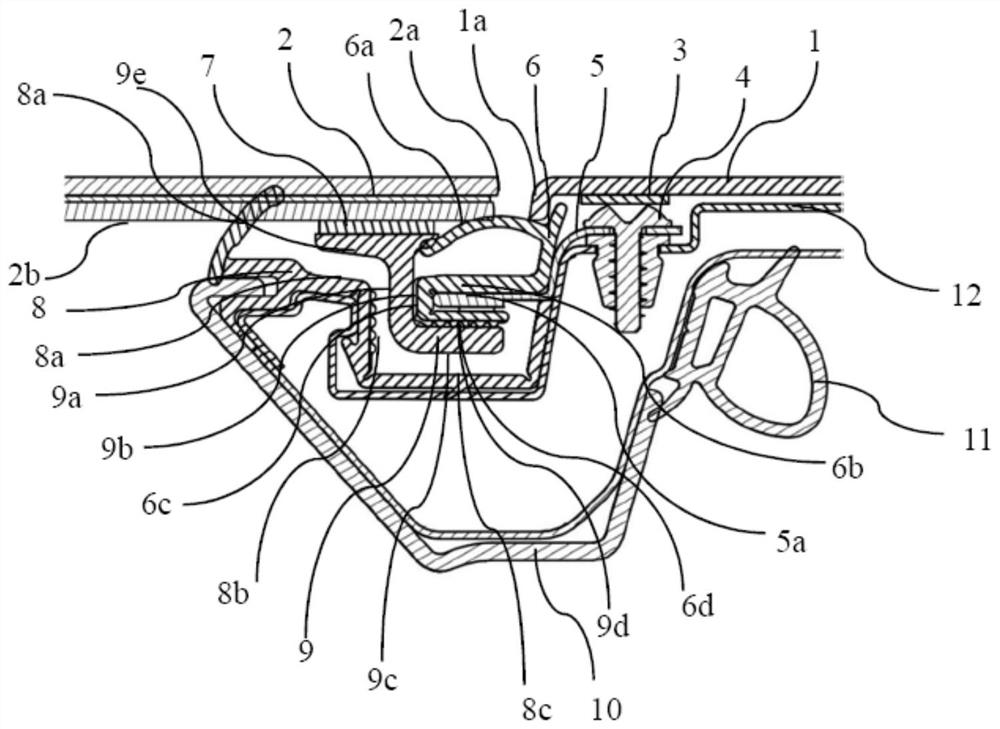

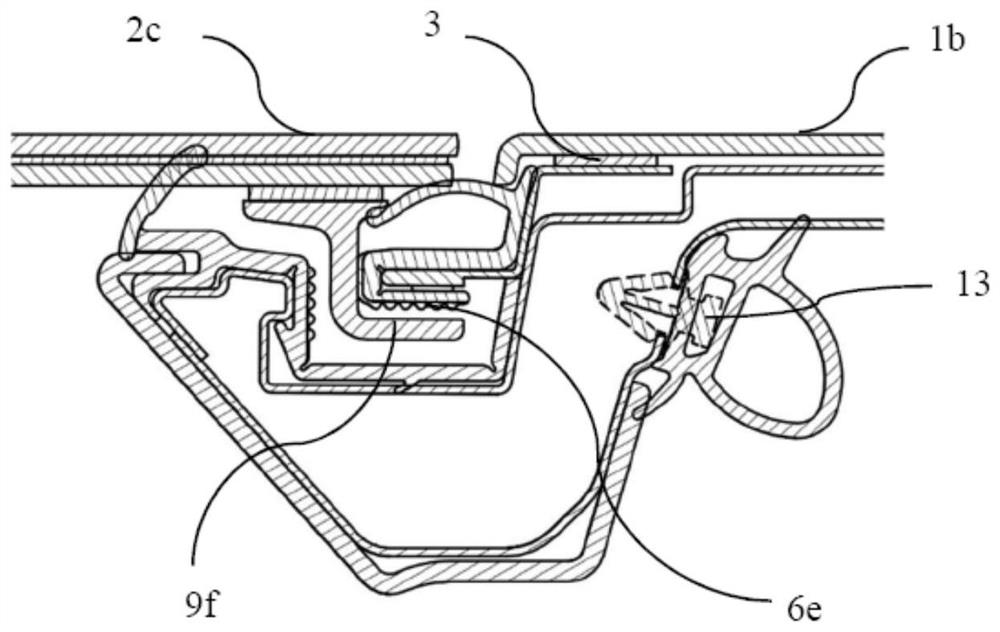

[0021] Such as figure 2 As shown, the door glass lifting slider 9 is bonded to the door glass inner side 2b near the door glass edge 2a by glue 7, and the door glass lifting guide rail 5 is fixed on the door window frame 12 by screws 4. The door glass lift guide rail sealing strip 6 is supported on the door glass lift guide rail flange 5a, the door glass lift guide rail sealing strip second limiting surface 6d and the door glass lift slider second limiting surface 9d are attached, and the door glass 2 is moved along the door. Inside and outside limit. The first limiting surface 6c of the sealing strip of the door glass lifting guide rail is bonded to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com