Paper delivery device and paper delivery table

A technology in the paper output table and device, which is applied in the field of paper output device and paper output table, can solve the problems of product quality hidden dangers, standby, spacer paper waste, etc., to eliminate static interference, avoid mutual adsorption, and improve paper output smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

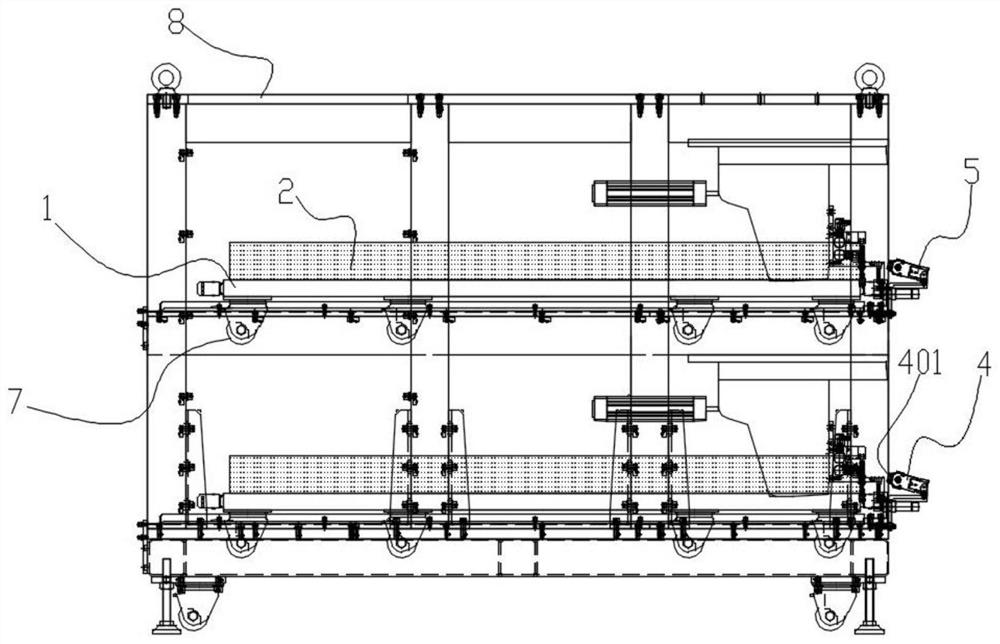

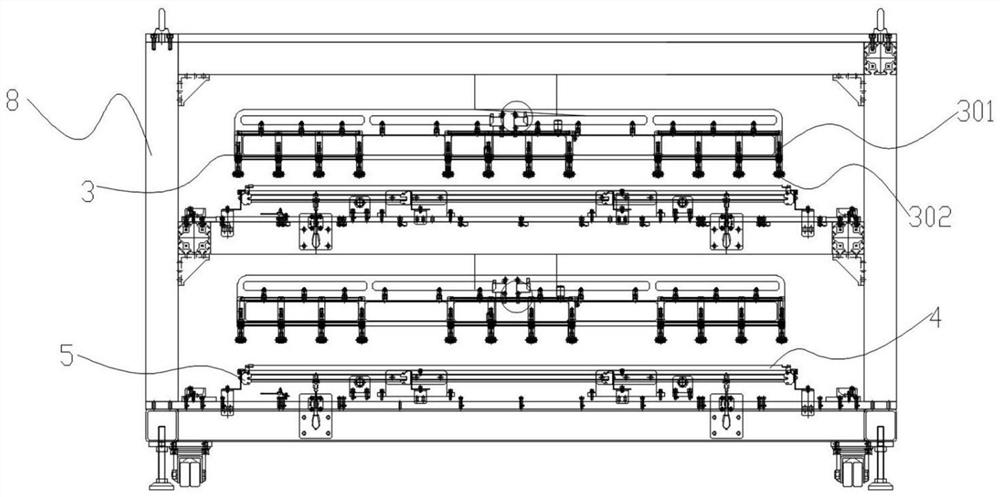

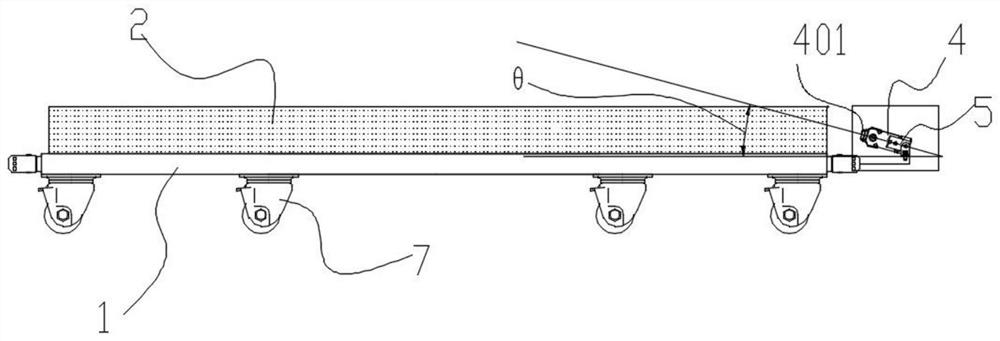

[0035] In the embodiment of the present invention, a new type of paper output device is provided, which is applied in the technical field of paper separation. The paper output device in this embodiment is arranged in the paper output table 8, specifically, the paper output table 8 is used for An output table for ultra-thin glass packaging. The spacer paper used for packaging ultra-thin glass is placed in the carton 1, and the front end of the spacer paper is sucked up by the paper suction mechanism 3, and then moved to the set position by the air cylinder in the paper suction mechanism 3, and the spacer paper is held by the gripper The paper-taking robot takes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com