A glass panel polishing machine tool and polishing method

A glass panel and machine tool technology, applied in the field of polishing machine tools, to avoid static electricity, reduce labor costs, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the examples, which are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0039] This embodiment is a preferred implementation of the present invention, and any alternative content should be included within the protection scope of the present invention.

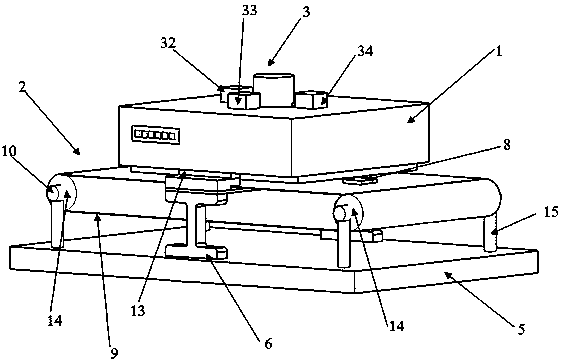

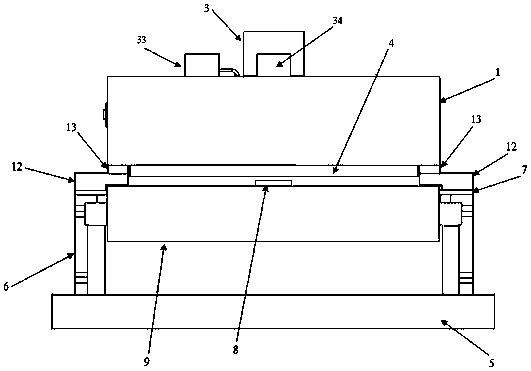

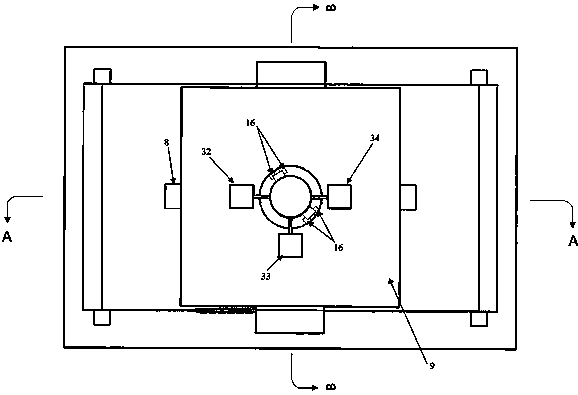

[0040] In one embodiment, the present invention provides a glass panel automatic polishing machine, such as figure 1As shown, it includes a cover body 1, a transmission mechanism 2, a polishing device 3, a polishing powder feeding assembly, a polishing liquid feeding assembly, a cleaning liquid feeding assembly, a shock-absorbing support device, and a substrate 5; There is a cylindrical through hole, the polishing device 3 passes through the through hole, and the polishing device 3 is raised and lowered by the lifting mechanism; the cover body 1 is installed above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com