Automatic deviation rectifying system of crude foil engine

An automatic deviation correction and foil machine technology, which is applied in thin material handling, transportation and packaging, and winding strips, etc., can solve problems such as deviation of formed foil, unevenness of formed foil rolls, and low quality of copper foil winding , to achieve the effect of not easy to be damaged and flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

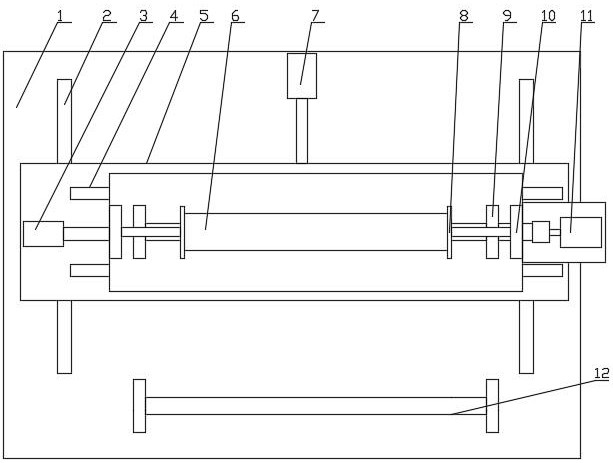

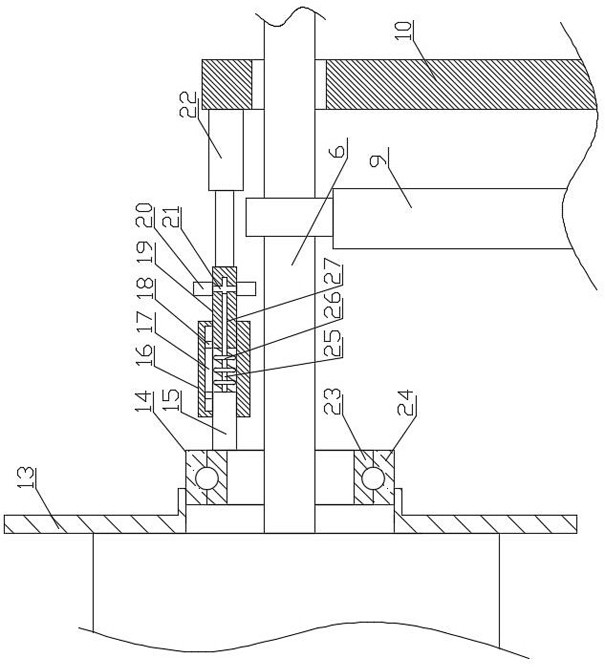

[0028] Such as Figure 1-4 Shown: an automatic deviation correction system for a raw foil machine, including a base 1, a translation mechanism set on the base 1, and a winding mechanism set on the translation mechanism, and a regularizing mechanism 8 is set at both ends of the winding mechanism. The front end is provided with a pressing mechanism 12;

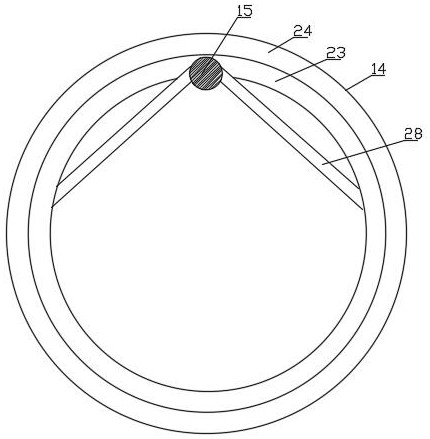

[0029] The winding mechanism includes a first bracket 9 provided on the translation mechanism, and the winding roller 6 is rotated on the first bracket 9, and the regularizing mechanism 8 includes a second bracket 9 arranged on the translation mechanism outside the first bracket 9. The bracket 10, the second bracket 10 is provided with a first telescopic mechanism 22 inwardly, and the front end of the telescopic mechanism is rotated and provided with an annular push plate 13 .

[0030] Specifically, the copper foil comes out from the bottom of the pressing mechanism 12 and is wound up into the winding mechanism. The winding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com