Circulating assembly type building structure based on green building material production

A technology of green building materials and building structures, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems that cannot meet the needs of actual use, the structure of wall components is unstable, and the application cost is high, so as to achieve structural stability and stability The effect of lifting and improving tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

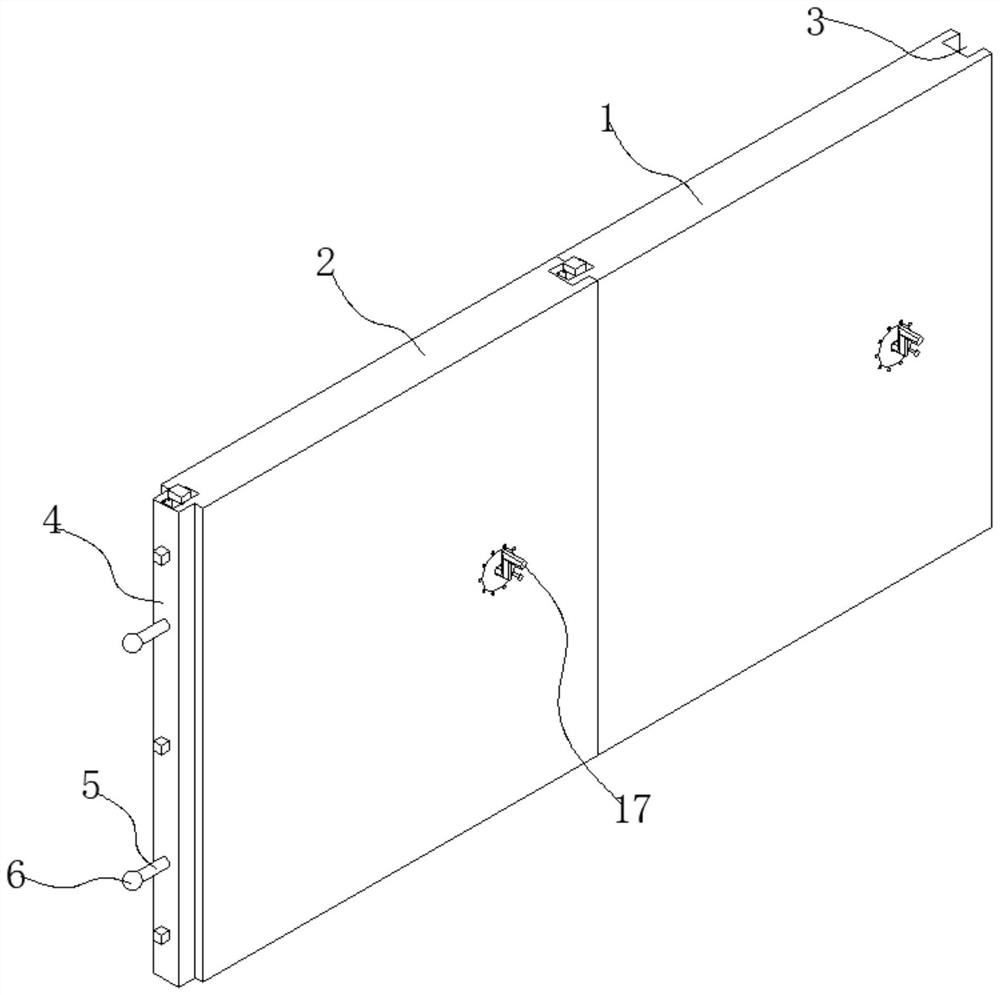

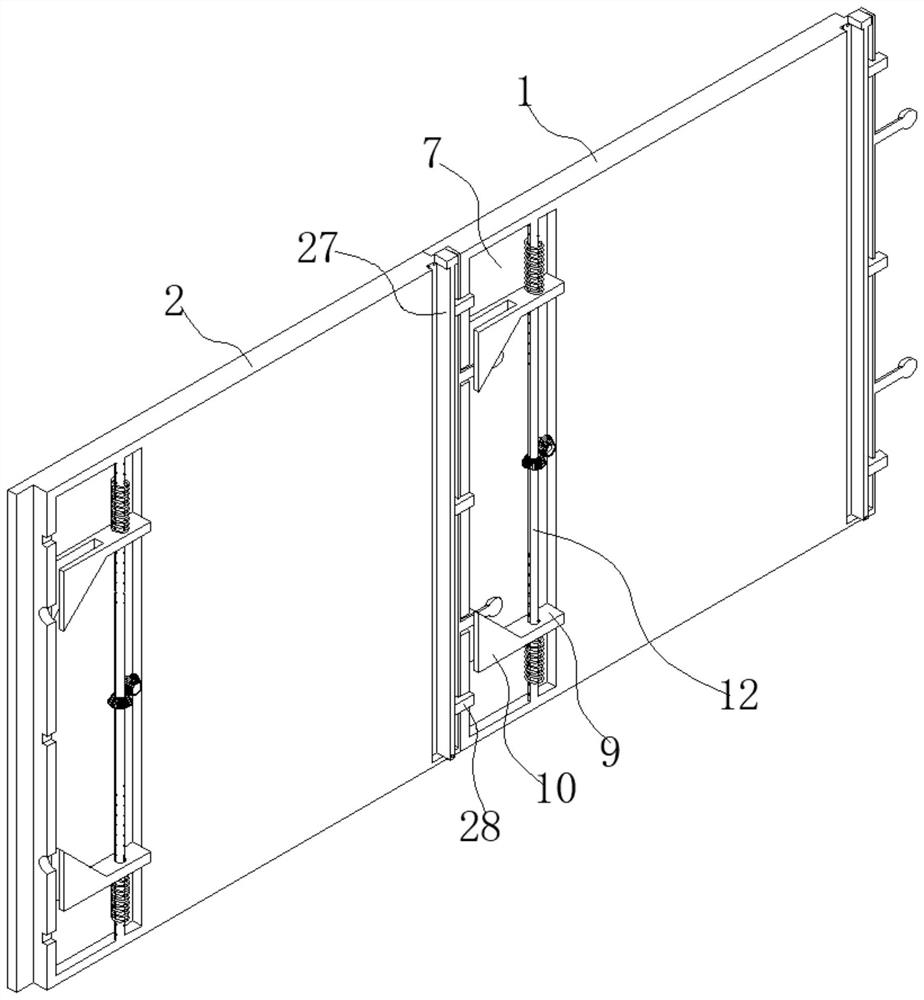

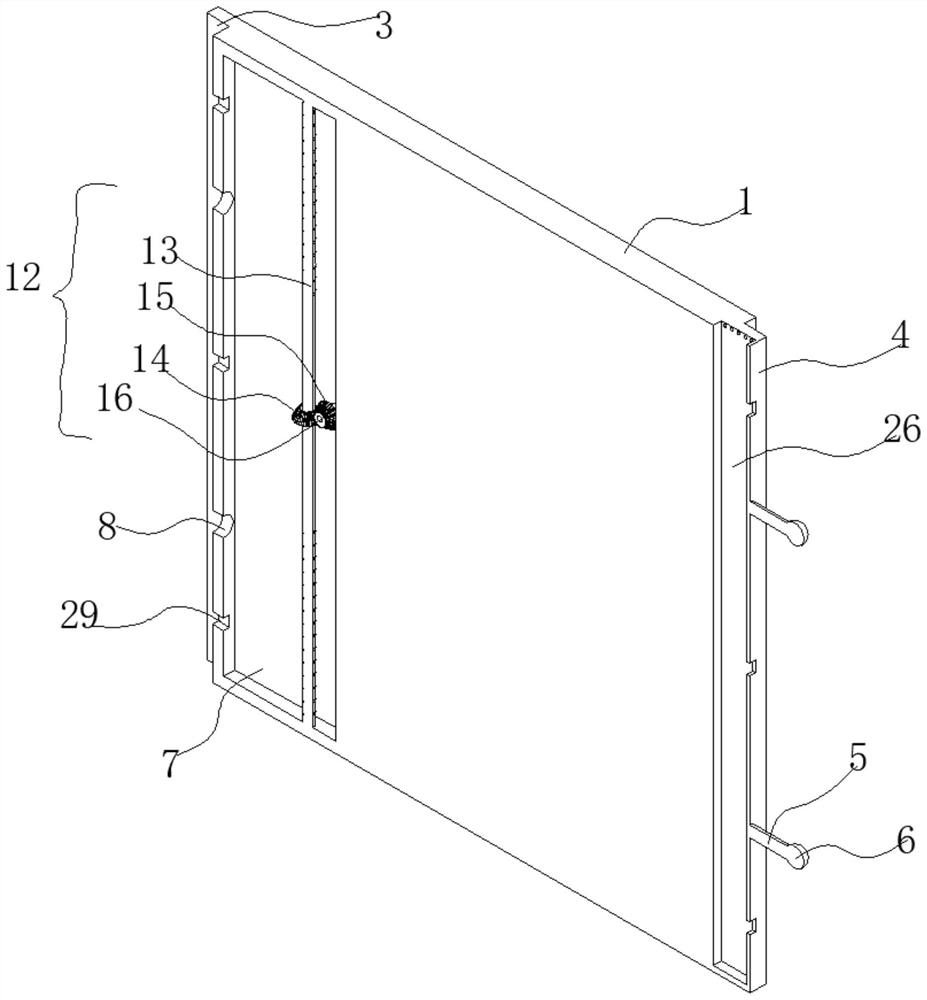

[0036] See Figure 1-13 As shown, the present invention is a circulating assembled building structure produced by green building materials, including the main attachment wall 1 and the secondary connecting wall 2, the main connection wall 1 and the auxiliary wall 2, and more mainly coupled walls 2. The main connection wall 1 and the secondary tail mutual stitching combination, the main connection wall 1 side is opened, and the connecting card slot 3 runs through the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com