A prefabricated prestressed concrete composite beam with cast-in-place conical connectors and its construction method

A technology of conical connectors and concrete, which is applied in the direction of load-bearing elongated structural components, building components, buildings, etc., can solve the problems of component instability, difficulty in ensuring prestressing, and difficult prestressing of concrete, etc., to achieve The effect of increased strength, fast construction speed and high prefabrication rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

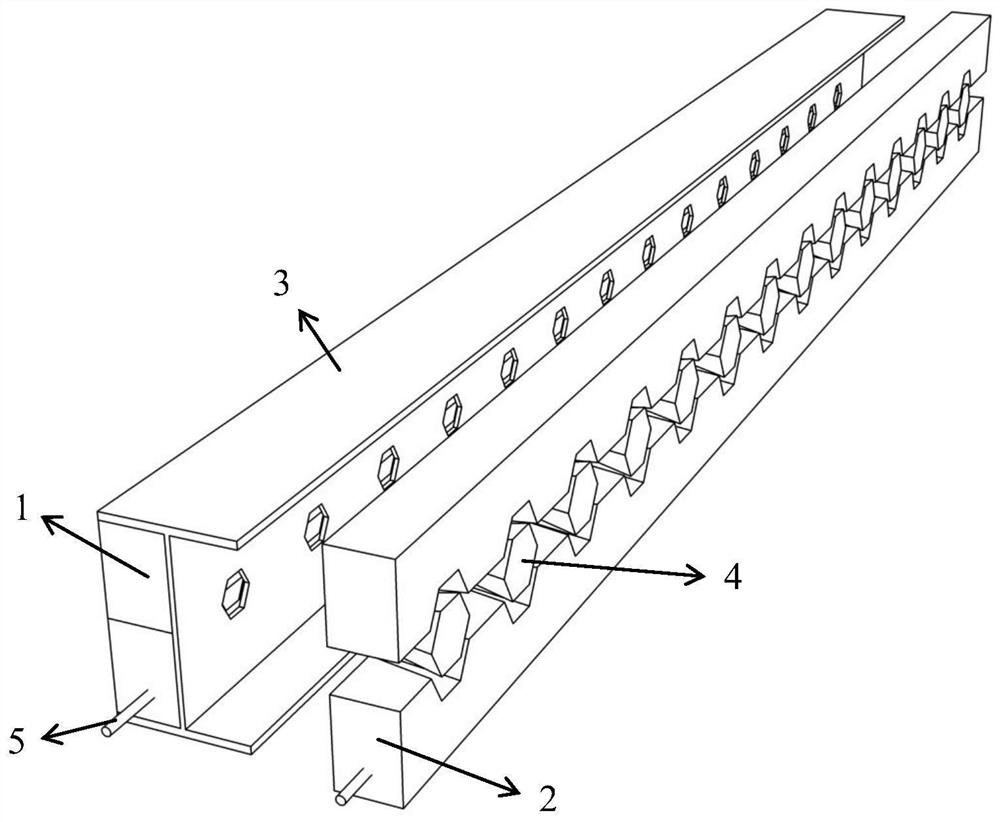

[0037] like figure 1 As shown, a prefabricated prestressed concrete composite beam with cast-in-place conical connecting pieces, comprising:

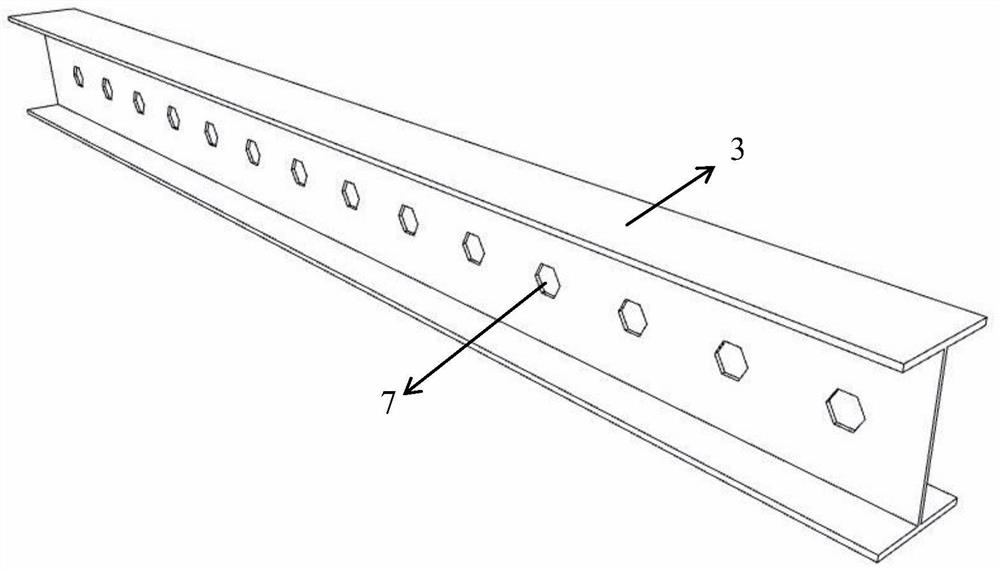

[0038] Honeycomb type I-beam 3, reference figure 2 , there are holes 7 on its web. For example, the holes 7 are regular hexagons, and the plurality of holes 7 are evenly arranged along the length direction of the honeycomb-shaped I-beam 3 . In the up-down direction, there is generally only one row of holes 7, but multiple rows can also be provided according to actual conditions such as size and strength requirements. When multiple rows are provided, the holes 7 in each row may be located in the same vertical direction, or may be staggered in the up-down direction.

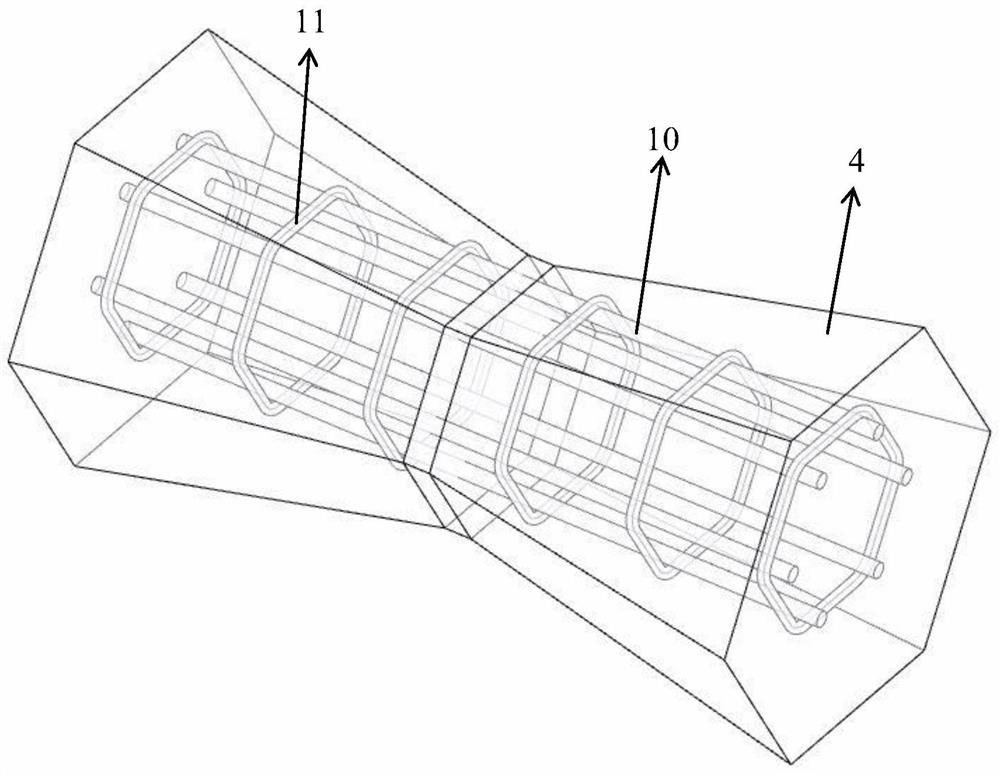

[0039] The split concrete strips are arranged on both sides of the web of the honeycomb I-beam 3, and between the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com