Cheese plate of large electronic clean workshop and construction method

A technology for cleaning workshops and construction methods, applied in the direction of formwork/template/work frame, connection parts of formwork/formwork/work frame, housing structure support, etc., which can solve the problems of time-consuming assembly and poor Cheese board effect. , to achieve the effect of increasing the sealing performance, shortening the project schedule, and improving the construction efficiency of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

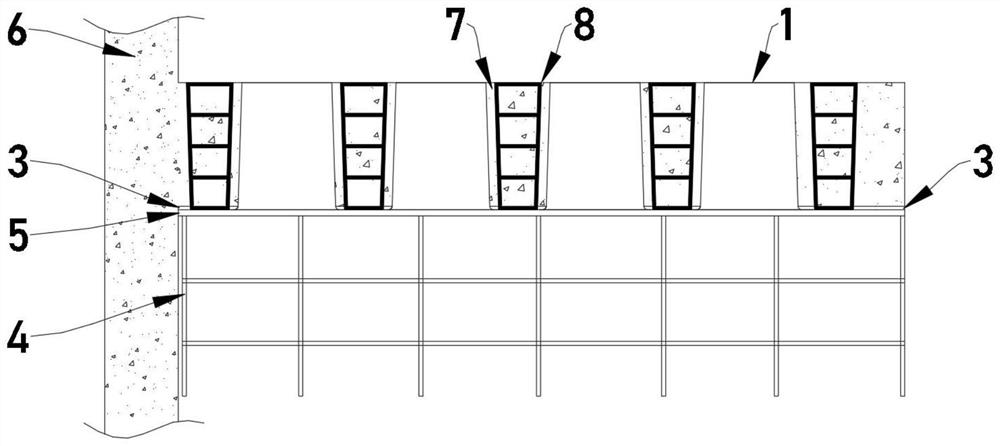

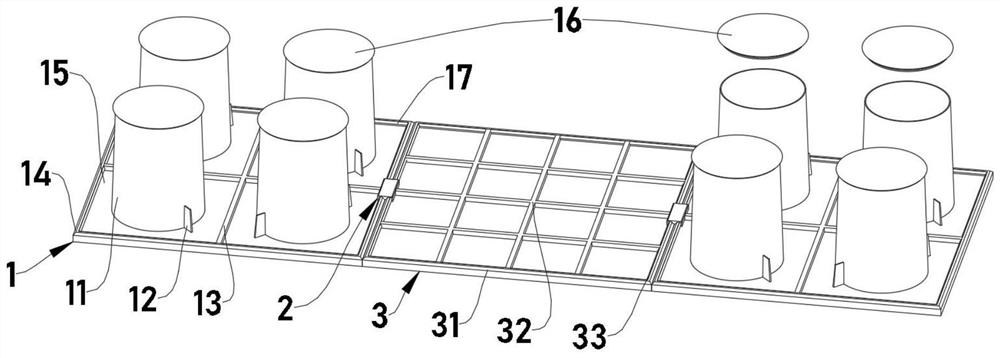

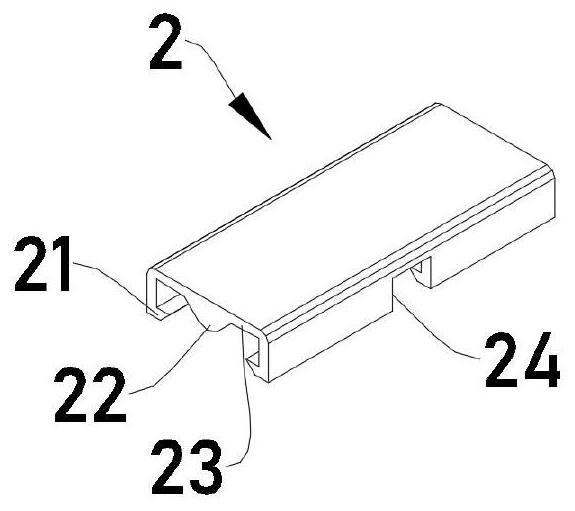

[0049] see Figure 1-9 , the present invention provides a kind of Cheese board of large-scale electronic clean factory building, by erecting full frame 4 on the floor of the lower floor, full frame 4 is fixedly connected with structural column 6, and template 5 is laid on the top of full frame 4 to make, including SMC formwork 1, Multiple sets of SMC formwork 1 are laid on the top of the template 5, and the SMC formwork 1 is fixedly connected and positioned with the adjacent SMC formwork 1 or formwork 1 connecting plate 3 through the positioning clip 2.

[0050] SMC formwork 1 comprises base plate 15, and the top of base plate 15 is uniformly provided with at least one hole mold 11, and the inside of hole mold 11 is hollow and top and bottom opening, and hole mold 11 is evenly arranged between the bottom of outer wall and the top of base plate 15. Reinforcing ribs 12, positioning ribs-13 are provided at the central position of the top of the base plate 15, guide chamfers-14 ar...

Embodiment 2

[0062] see Figure 6 , a kind of construction method of Cheese board of large-scale electronic clean workshop, comprises the following steps:

[0063] Step S1, formwork 1 matching plate, calculate the specific quantity of SMC formwork 1, formwork 1 connecting plate 3 and positioning clip 2 of various specifications required according to the design requirements of the drawing, and carry out spare parts, the periphery of the structural column 6 and the beam Next, the cuttable formwork 1 connecting plate 3 is used for construction;

[0064] Step S2, Cheese board production, use the five-step leveling method to carry out construction on the following steps;

[0065] Step S21, constructing the skeleton, first set up a full hall frame on the surface of the lower floor, and use the bottom bracket and the upper bracket, and then lay the building formwork 5, the building formwork 5 is made of wood plywood, and reserve 5mm at the joints to avoid deformation and warping of the formwork ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap