Mining wet dust collector and dust collection method thereof

A wet dust collector and mine-used technology, applied in dust prevention, mining equipment, earth square drilling and mining, etc., can solve the problems of secondary dust, large volume, high cost of filter use and maintenance, and achieve the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

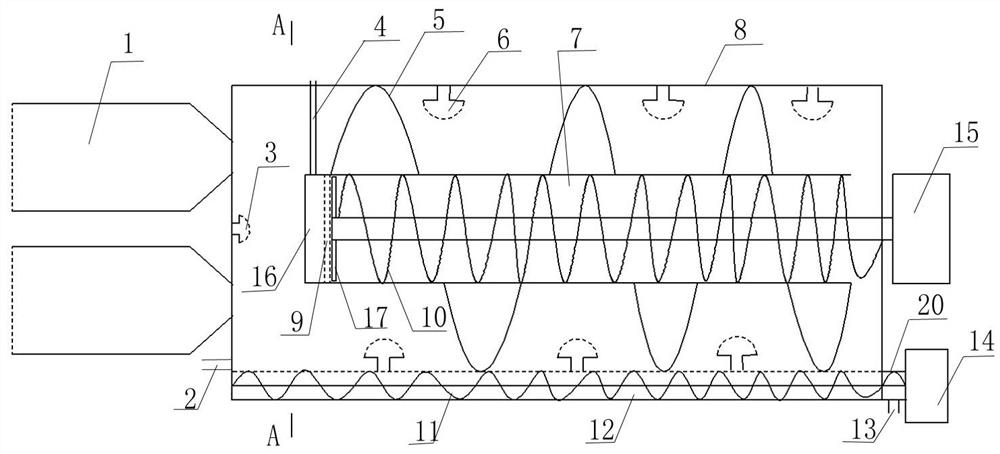

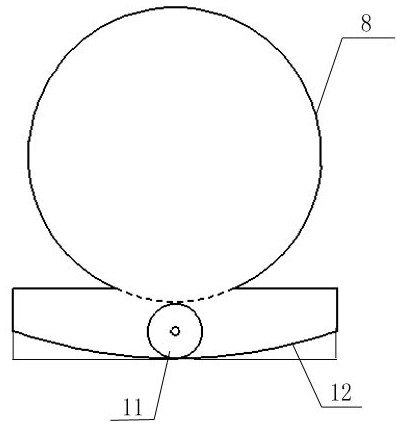

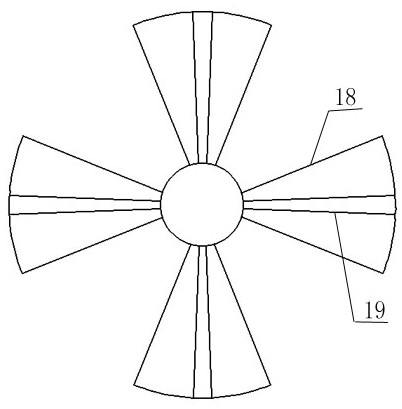

[0018] Such as figure 1 As shown, a mining wet dust collector includes a main cylinder 8, a base 12 of the main cylinder 8, and an air cylinder 1 installed on the main cylinder 8. The main cylinder 8 is a horizontally placed cylinder, and the main cylinder 8 has a A horizontally placed cylindrical purification pipe 7 with an open right end, the inner wall of the main cylinder 8 and the outer wall of the purification pipe 7 are fixedly connected by a spiral connecting plate 5 (the spiral connecting plate 5 is spirally connected from right to left, and the thickness does not exceed 3mm), There are patterns on the surface of the spiral connecting plate 5, which is more likely to cause dust gas to condense. There is a gap of 20-30cm between the left side wall of the main cylinder 8 and the left side wall of the purification pipe 7. Sufficient water spraying space, on the other hand, is convenient to form a stable deposition area below, and is convenient for pumping water. There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com