Heat insulation connecting column

A connecting column and heat insulation technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of high thermal conductivity of metal materials, low energy saving rate of products, and failure to achieve the use effect, etc., to achieve low thermal conductivity , long service life and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

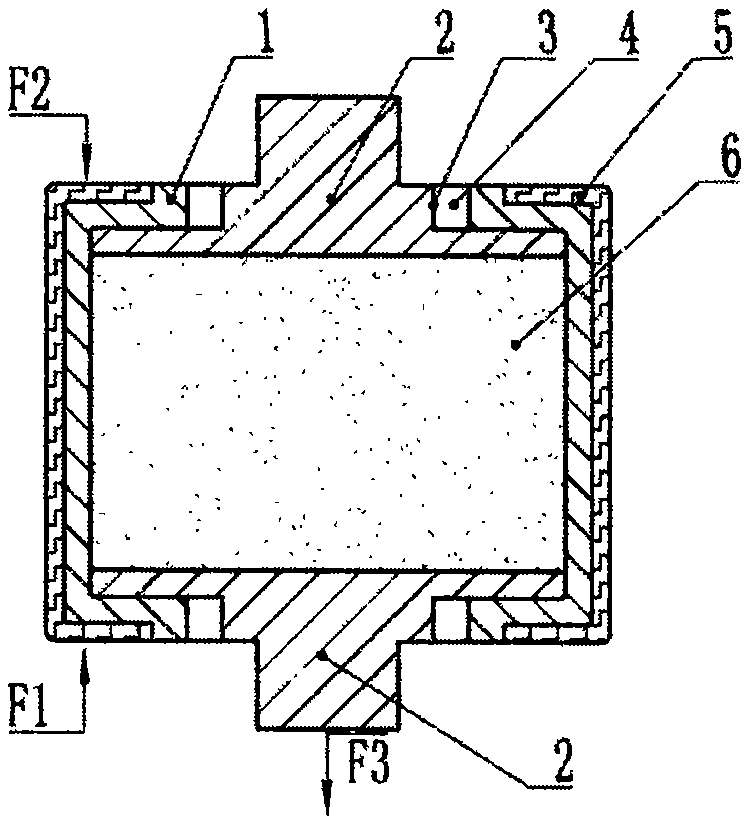

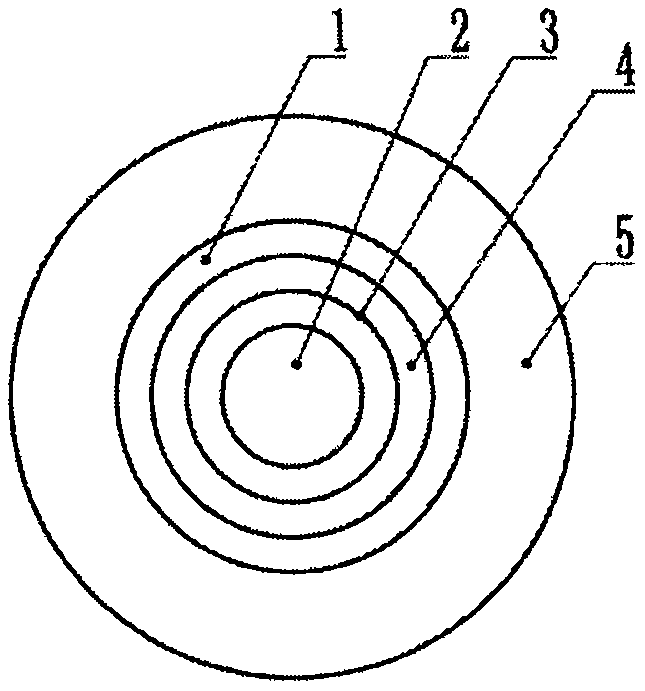

[0015] Such as figure 1 figure 2 The present invention provides a heat-insulating connecting column, which includes the upper and lower parts of the housing 1 and the end cover screw 2 with straight openings 3 bending welds 4, the outer shell 1 is provided with a hardened layer 5, the shell 1 and the Uniform spherical particles 6 are arranged inside the top and bottom symmetrical end cap bolts 2 .

[0016] In actual implementation, the material of the shell 1 is 316 material, and its exterior is provided with a hardened layer 5 with a thickness of 10-200um. Due to the increase in the process performance of the hardened layer 5, its tensile strength is the same as that of the original material. In comparison, the mechanical properties are increased by 118% to 462%, respectively, and the heat transfer cross-sectional area of the shell 1 wall thickness is thinned, so it has the technical advantages of small volume, less heat conduction, and high tensile strength.

[0017] Sp...

Embodiment 2

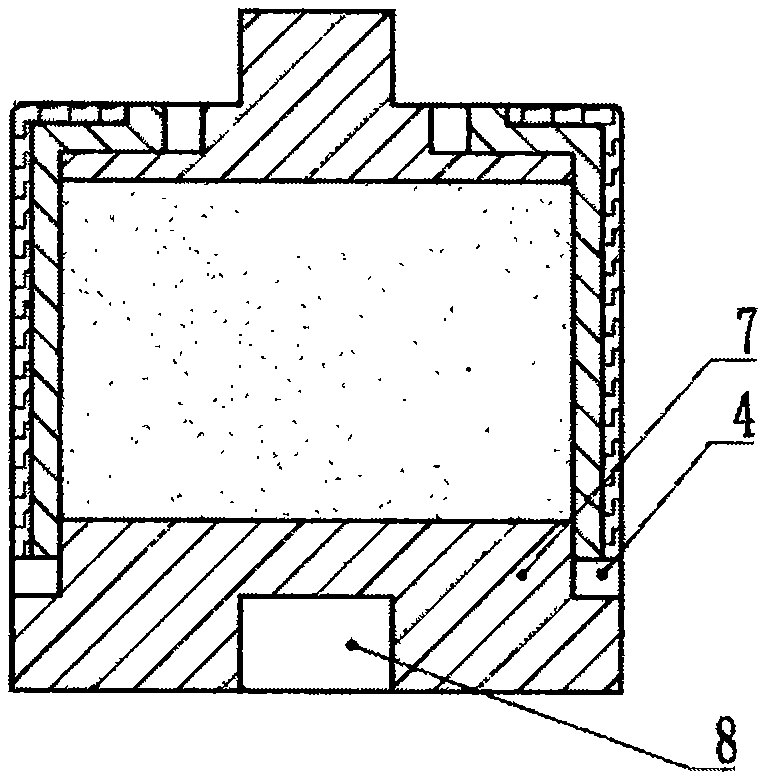

[0020] The difference between Embodiment 2 of the present invention and Embodiment 1 is that the lower part of the heat-insulating connecting column is provided with a nut seat 7 with thread 8 and welded 4 with the shell 1 as a whole.

[0021] In practice, since the lower nut seat 7 of the heat-insulating connecting column is provided with thread 8, bolts can be used for connection, which increases the scope of application.

Embodiment 3

[0023] The difference between Embodiment 3 of the present invention and Embodiment 1 is that the lower part of the heat insulating connecting column is provided with a cross opening 10 and an end cap 9 which is larger than the size of the shell.

[0024] In practice, since the lower part of the end cap 9 which is larger than the size of the shell is provided with a cross opening 10, it can be directly communicated with other components, increasing the scope of application.

[0025] The technical solution provided by the embodiments of the present invention has the following advantages:

[0026] The heat insulating connecting column provided by the embodiment of the present invention has the advantages of small volume, low thermal conductivity, high compressive strength and high tensile strength due to the optimized combination of structure, material and process between the shell and the end cap and the spherical particles inside. , The advantages of long service life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap