Tractor synchronizer gear shifting oil cylinder, gear shifting method and tractor

A shift cylinder and synchronizer technology, which is applied in the field of tractors, can solve problems such as sticking, high failure rate, and reduced response speed of the oil cylinder, and achieve the effect of stable and fast shifting process and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

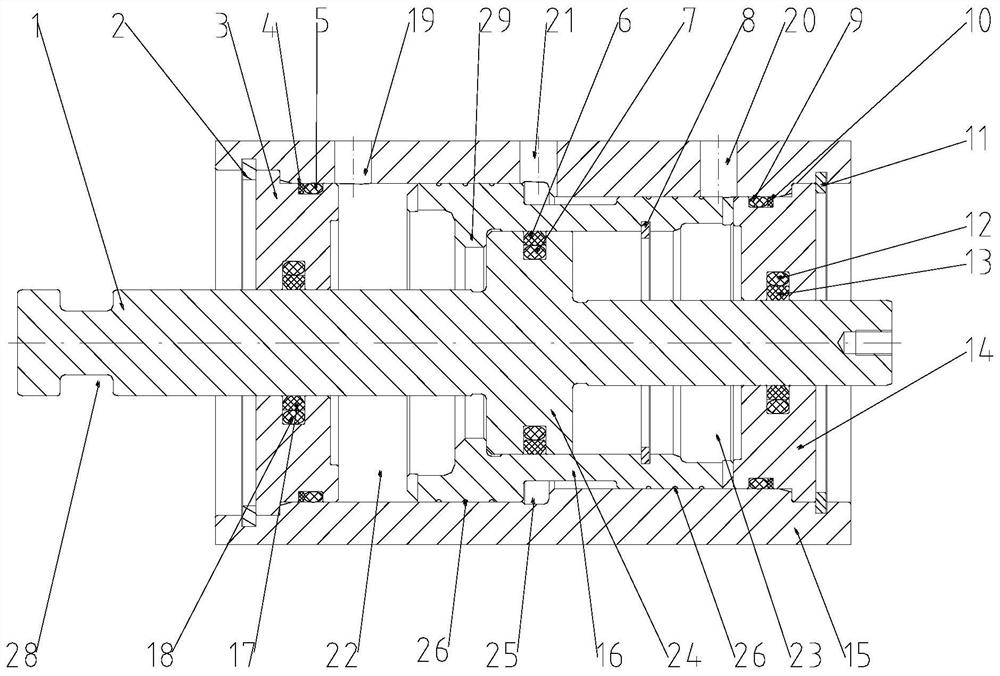

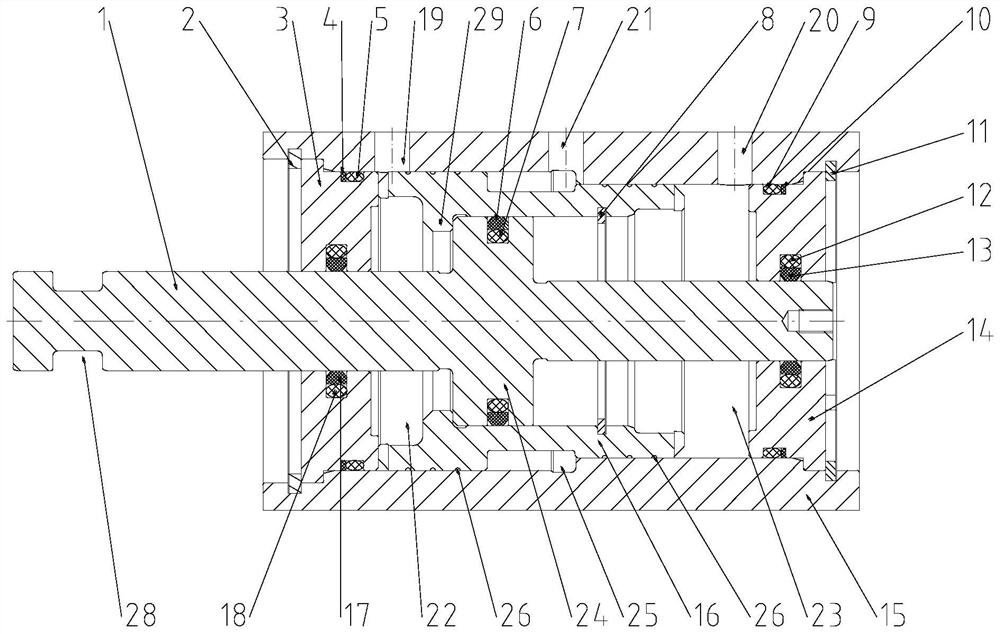

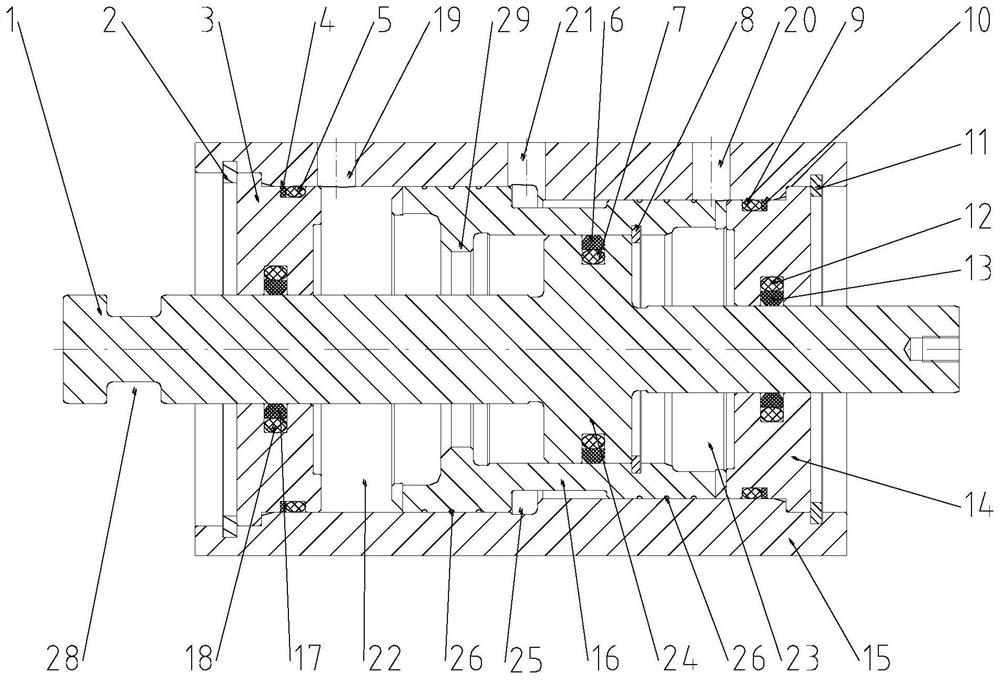

[0040] Such as Figure 1 to Figure 7 As shown, a kind of tractor synchronizer shift oil cylinder of this embodiment includes a piston rod 1, a cylinder body 15 and a positioning piston 16, and the positioning piston 16 is arranged in the cylinder body 15 capable of axial movement, and the The piston rod 1 is sealed and pierced on the cylinder body 15 and can move axially relative to the cylinder body 15; the positioning piston 16 has a cylindrical structure, and the piston rod 1 is sleeved in the positioning piston 16. The middle part of the piston rod 1 is provided with a piston 24, the peripheral side wall of the piston 24 is in sealing connection with the inner side wall of the positioning piston 16 and can move axially relative to the positioning piston 16, and the piston 24 moves the cylinder body 15 The cavity is divided into a first cavity 22 and a second cavity 23; the cylinder 15 is provided with a first oil port 19 and a second oil port 20, and the first oil port 19 ...

Embodiment 2

[0056] A shift method of the present embodiment using the above-mentioned tractor synchronizer shift cylinder includes the following steps:

[0057] The piston rod 1 is connected to the load. Specifically, the load connection notch 28 on the piston rod 1 can be used to connect to the load, and the load is a shift fork;

[0058] The first oil port 19 and the second oil port 20 supply pressure oil at the same time, so that the positioning piston 16 is positioned on the right side of the cylinder body 15, and the piston 24 on the piston rod 1 is positioned on the left side of the positioning piston 16;

[0059] The first oil port 19 releases pressure, the second oil port 20 supplies pressure oil, and the positioning piston 16 moves leftward to the limit position on the left side of the cylinder 15 under the action of the pressure oil provided by the second oil port 20, because the piston rod 1 The action is delayed by the action of the load. When the pressure of the pressure oil ...

Embodiment 3

[0063] A tractor in this embodiment includes the gear shift cylinder of the tractor synchronizer. The tractor adopting the above-mentioned shifting oil cylinder has a stable and quick shifting process and a low failure rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com