Firework lift-off device and operation method thereof

A technology of fireworks and fireworks, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as environmental pollution and hindering the development of fireworks economy, and achieve the effects of protecting the environment, eliminating harmful gases and smoke particles, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

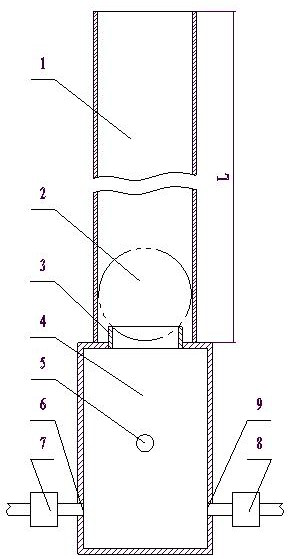

[0023] Example 1, such as figure 1 As shown, a firework lift-off device has a steel container with a closed bottom and an open upper end. The lower part of the container is a combustion chamber 4, and the upper part of the container is a guide channel 1. There is a fireworks support between the combustion chamber 4 and the guide channel 1. Flange 3, spherical fireworks (can also be replaced by cylinder fireworks) 2 are placed on the fireworks support flange 3, an arc igniter 5, a combustion-supporting gas input port 9 and a combustible gas input port 6 are provided on the side wall of the combustion chamber 4 to support combustion The gas input port 9 is connected to the combustion-supporting gas solenoid valve 8 through a pipeline, the combustion-supporting gas solenoid valve 8 is connected to the combustion-supporting gas cylinder (not shown in the figure) through a pipeline, and the combustible gas input port 6 is connected to the combustible gas solenoid valve 7 through a ...

Embodiment 2

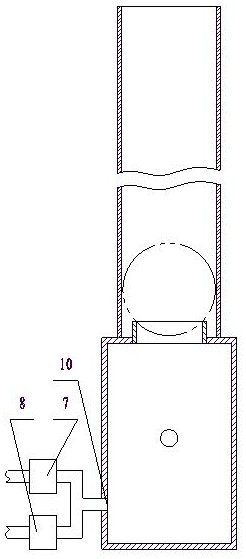

[0034] Example 2, such as figure 2 As shown, except that there is only one mixed gas input port 10, others are the same as in Embodiment 1. The mixed gas input port 10 is connected with the combustion-supporting gas solenoid valve 8 and the combustible gas solenoid valve 7 through the pipeline, the combustion-supporting gas solenoid valve 8 is connected with the combustion-supporting gas cylinder (not shown in the figure) through the pipeline, and the combustible gas solenoid valve 7 is connected with the combustible gas solenoid valve through the pipeline. Combustible gas cylinders (not shown in the figure) are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com