Method for deeply purifying flue gas of sintering machine and recycling waste heat of flue gas of sintering machine

A technology for deep purification of flue gas and recovery of waste heat. It is applied in the direction of combustion method, waste heat treatment, combustion type, etc. It can solve the problems of strong carcinogenic effect, body necrosis, health damage, etc., and achieve the effect of eliminating harmful gases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

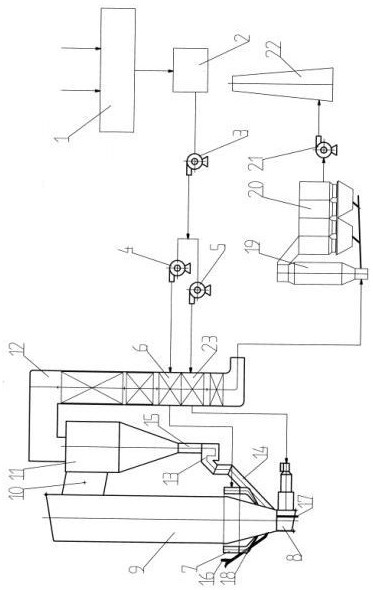

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

[0014] A sintering machine flue gas deep purification and waste heat recovery and utilization device, including sintering machine 1, sintering flue gas dust collector 2, spindle fan 3, secondary fan 4, primary fan 5, circulating fluidized bed boiler furnace 9, cyclone separation Device 11, tail flue 12, on the hearth 9 of the circulating fluidized bed boiler, a secondary hot air box 7 is arranged, at the bottom of the hearth 9 of the circulating fluidized bed boiler, a water-cooled air chamber 8 is arranged, and the tail flue 12 is set There are secondary air air preheater 6 and primary air air preheater 23, the working temperature in circulating fluidized bed boiler furnace 9 is higher than 900°C, the output flue gas port of sintering machine 1 and the input of sintering flue gas dust collector 2 The ends are connected together, the output end of the sintering flue gas dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com