Preparation method of LED light-emitting film

A light-emitting film and LED chip technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to form thin-film light-emitting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

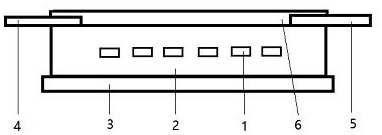

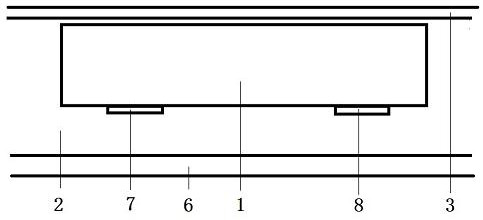

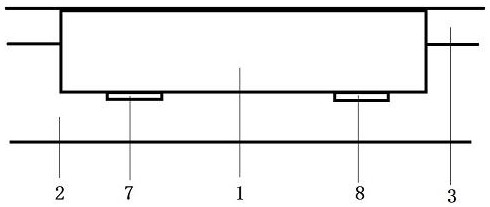

[0022] A method for preparing an LED luminous film, its structure comprises: a transparent base film 3 , an LED luminescent layer 2 , a positive electrode 4 , a negative electrode 5 , and a transparent protective film 6 . It is characterized in that the LED light-emitting layer 2 is formed by mixing the LED chip 1 and transparent glue containing conductive ions. Firstly, the transparent base film 3 provides a smooth plane base, and PET has better stability as a transparent base film, and can be used for the uniform preparation of the LED light-emitting layer. The LED light-emitting layer includes LED chips and transparent glue. The LED chips are arranged in an orderly manner or mixed with the transparent glue in a disordered manner. The LEDs are arranged in an orderly manner to display patterns and characters, and the mixed LEDs in disorder can produce double-sided, especially using alternating current. The number of LED chips contained in the LED light-emitting layer depends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com