Method for improving reliability of electromagnetic shielding film impedance matching requirement product

An electromagnetic shielding film and impedance matching technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve problems such as cost increase, achieve the effects of reducing residual copper rate, widening line width, and improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

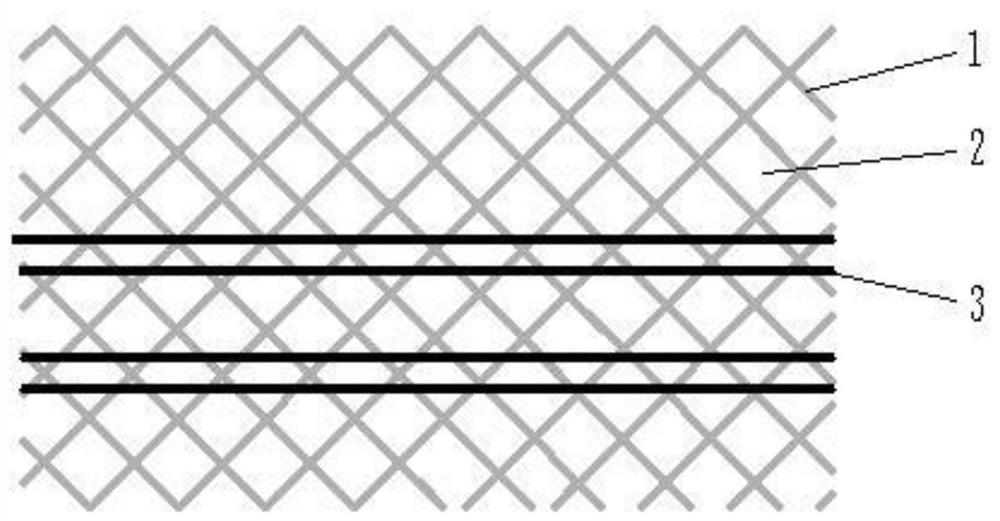

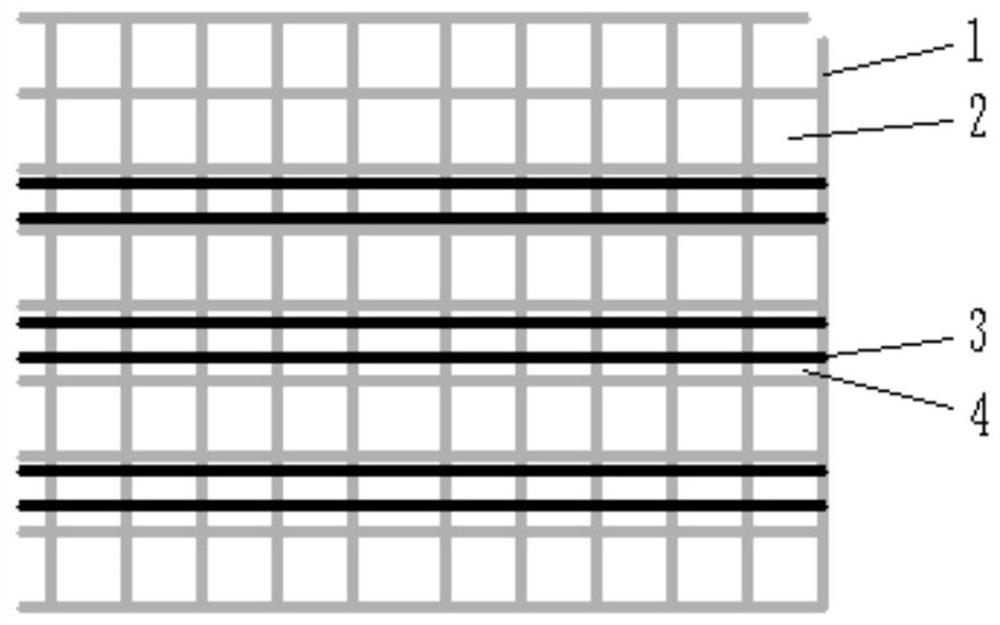

[0031] refer to figure 2 , a method for improving the reliability of products required for impedance matching of electromagnetic shielding films according to the present invention, laying differential signal lines in the signal layer of the circuit board, and laying two groups of intersecting grid lines in the reference layer below the differential signal lines 1 constitutes a grid copper layer, and the routing direction of the differential signal lines is the same as that of one group of grid lines 1 . In the conventional 45° grid copper layer design scheme, the differential signal lines are routed horizontally or vertically directly above the grid copper. Such routing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com