Screen, especially prepared for dust induced explosions and preferably usable in the wood-working industry

A screening, the best technology, applied to screening parts, to achieve the effect of space efficient and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

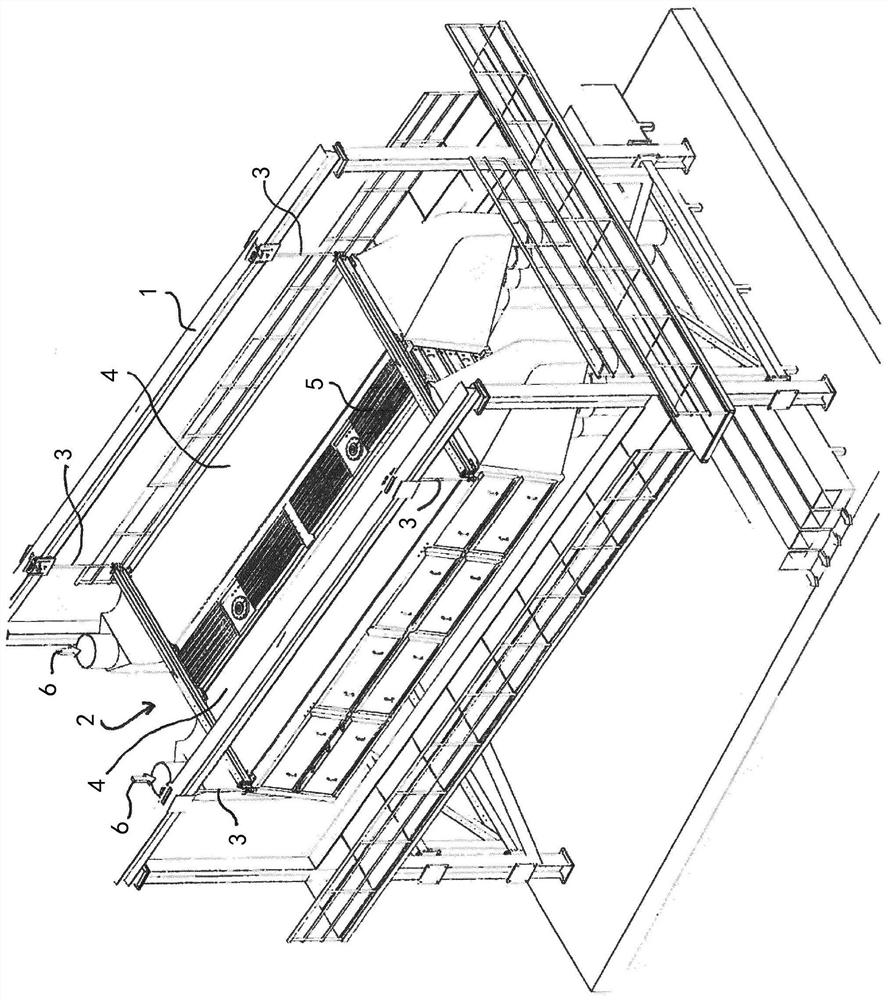

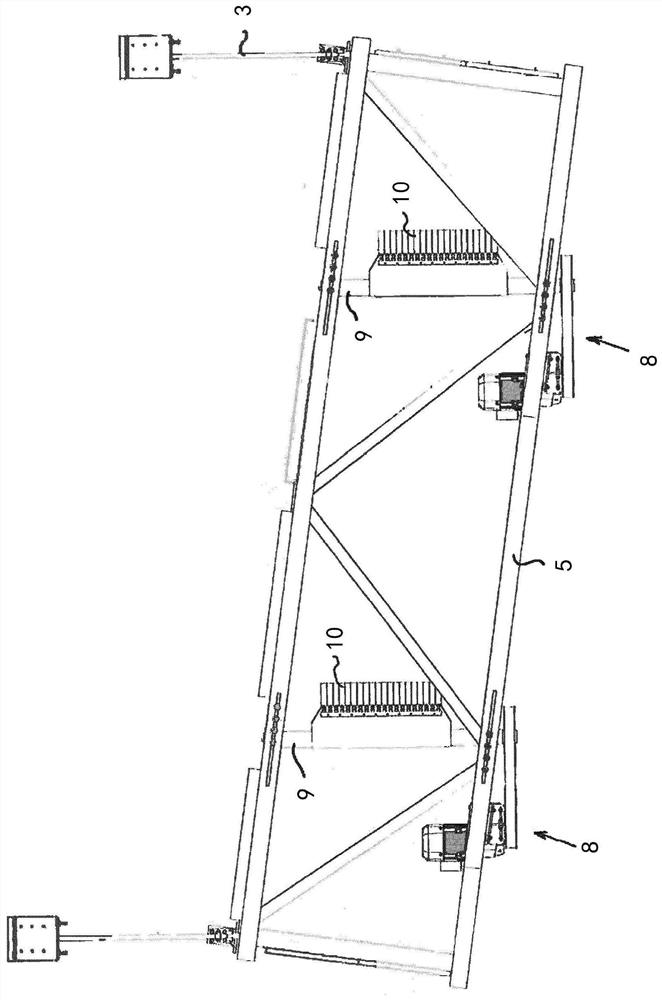

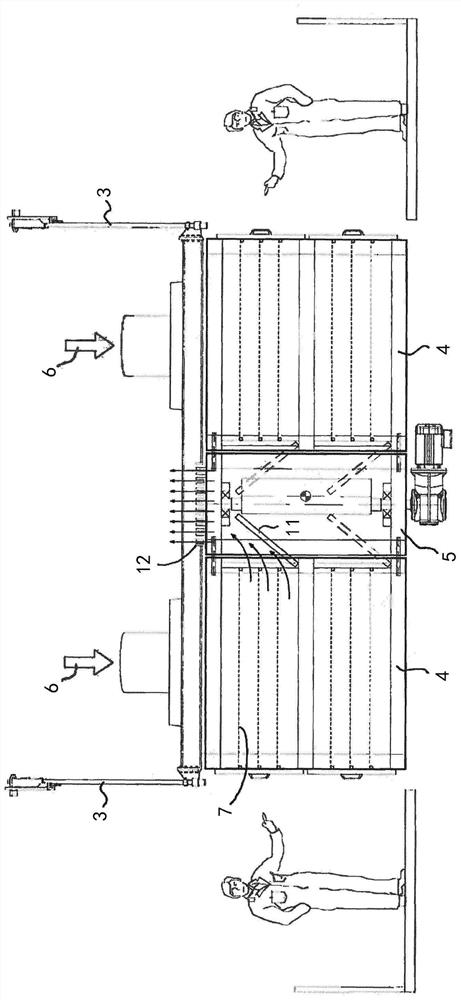

[0038] figure 1A screen according to an embodiment of the invention is shown viewed from the end. It consists of a frame structure and a moving part suspended from it. The moving part of the screen can also be supported from below instead of being suspended. Suspension is achieved here by means of the articulated rod 3 . Instead of the articulated rod 3 , the suspension can also be realized by means of steel cables. The moving part comprises two screen modules 4 and a frame module 5 between them. The screen module 4 comprises a screen chamber or a plurality of screen chambers substantially one above the other, which are structurally separated from each other, for example by a solid intermediate layer, in each screen chamber for screening The divided material is sieved into at least two fractions. In the figures an embodiment is shown in which the screens are double-layered, in other words there are two screen chambers one above the other in each screen module 4 .

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com