Optimised three-position switch

A three-position switch and path technology, applied in the direction of electric switch, grounding switch, high voltage/high current switch, etc., can solve the problem of reducing structural space, etc., and achieve the effect of compact structure, maximized dielectric strength, and simple movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

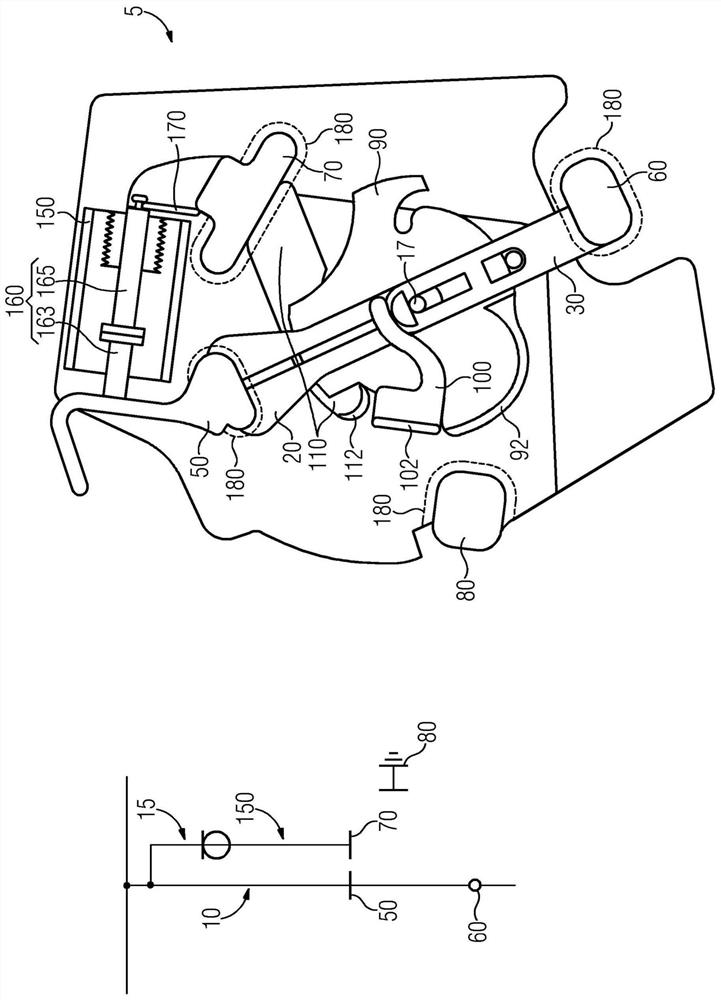

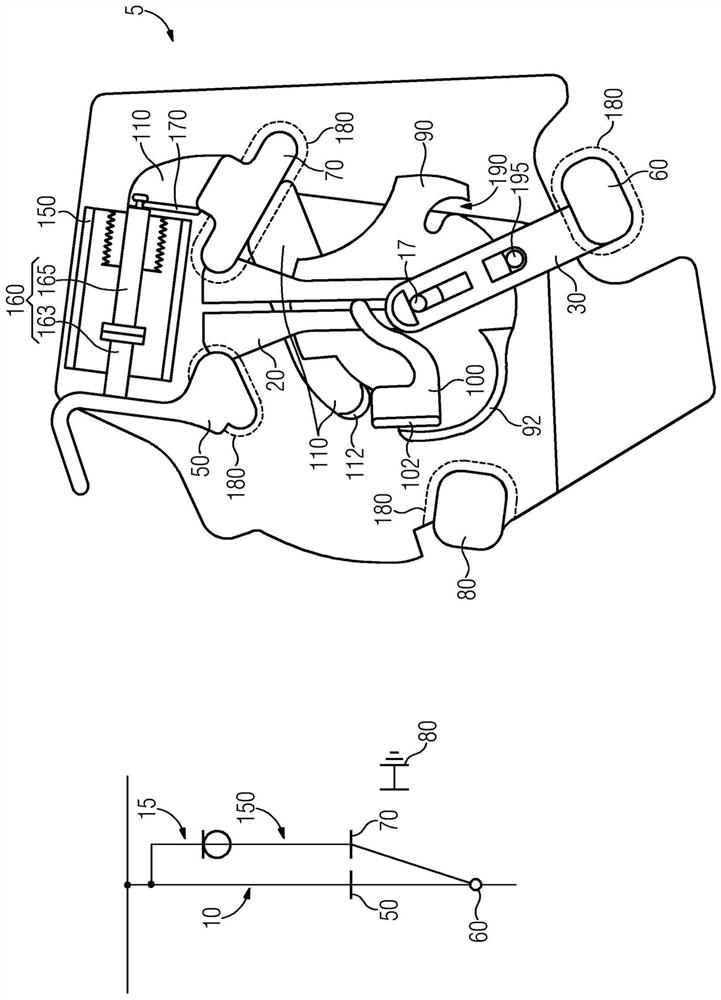

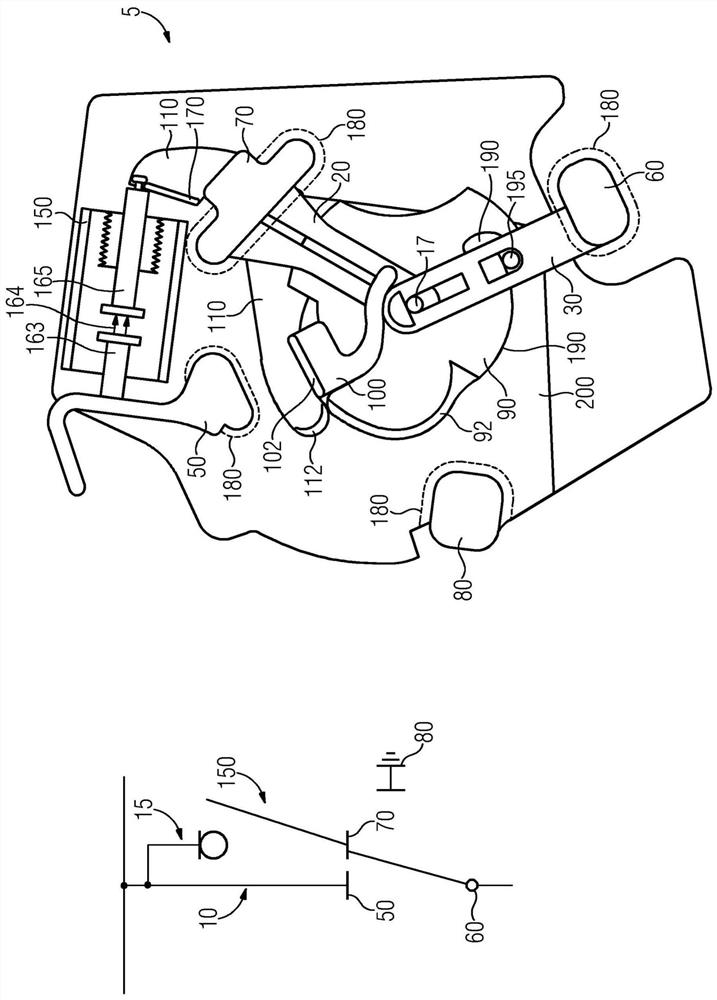

[0072] figure 1 On the left is shown the equivalent circuit diagram of a three-position switch 5 with a main current path 10, a bypass current path 15, a first main current path fixed contact 50, a second main current path fixed contact 60 , the bypass current path fixed contact 70, the grounding fixed contact 80 and the arc extinguishing device 150 (here a vacuum switching tube).

[0073] exist figure 1On the right side of , a schematic diagram of the three-position switch 5 according to the invention is shown in the "on" position. The three-position switch 5 has a bypass current path formed by an arc extinguishing device 150, and has an arc extinguishing contact 160, that is, an arc extinguishing fixed contact 163, an arc extinguishing movable contact 165, an arc extinguishing movable contact 165 and a bypass current path The contact strip 170 between the fixed contacts 70 and the bypass current path to the fixed contacts 70 . Furthermore, the three-position switch 5 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com