Diesel engine multi-point distribution type guide bench combustion chamber

A guide table and combustion chamber technology, applied in combustion engines, mechanical equipment, machines/engines, etc., can solve the problem of low utilization of combustion chamber headspace space, and achieve the effect of reducing NOx emissions, improving economy, and improving combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

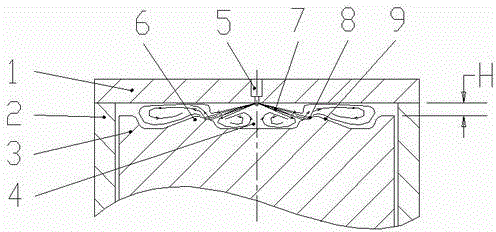

[0031] figure 1 A schematic diagram of the structure of the multi-point distributed guide platform combustion chamber of the diesel engine is shown. In the figure, the porous fuel injector 5 of the combustion chamber of the multi-point distributed guide table of the diesel engine sprays the high-pressure fuel into the combustion chamber 4 composed of the cylinder head 1, the cylinder liner 2 and the piston 3 in the form of multiple oil beams, and the combustion The chamber 4 increases the height H of the head gap and provides a plurality of guide platforms 6 . The mist-like oil jets 7 sprayed from the multi-hole injectors are sprayed onto each guide platform, a part of the oil beams is rebounded for secondary atomization, and a part hits the guide platforms and scattered to the surroundings to achieve better spatial mixing of oil and gas. The guide platform includes a collision surface 8 and a guide surface 9 .

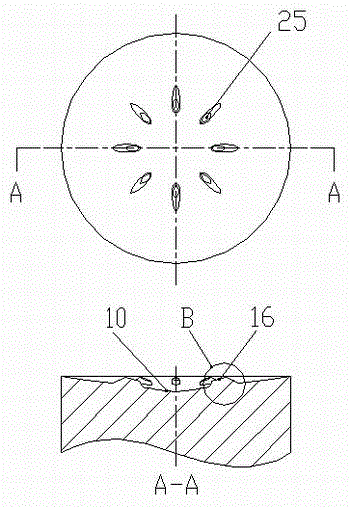

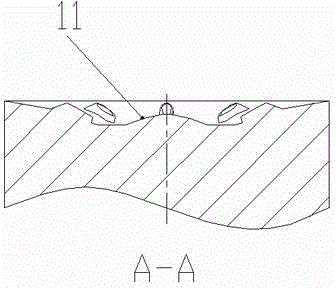

[0032] figure 2 , 3 , 4 show the structural schematic diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com