Omnidirectional tactile manipulator

A manipulator and tactile technology, applied in the field of robotics, can solve the problems of unfavorable manipulator perception and interaction ability, low perception accuracy of tactile sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are intended to illustrate the invention, but not to limit the scope of the invention.

[0025] It should be understood that various information is described in the present invention, but these information should not be limited to these terms, which are only used to distinguish the same type of information from each other. For example, "before" information may be referred to as "post" information without departing from the scope of the invention, "post" information can also be referred to as "prior" information.

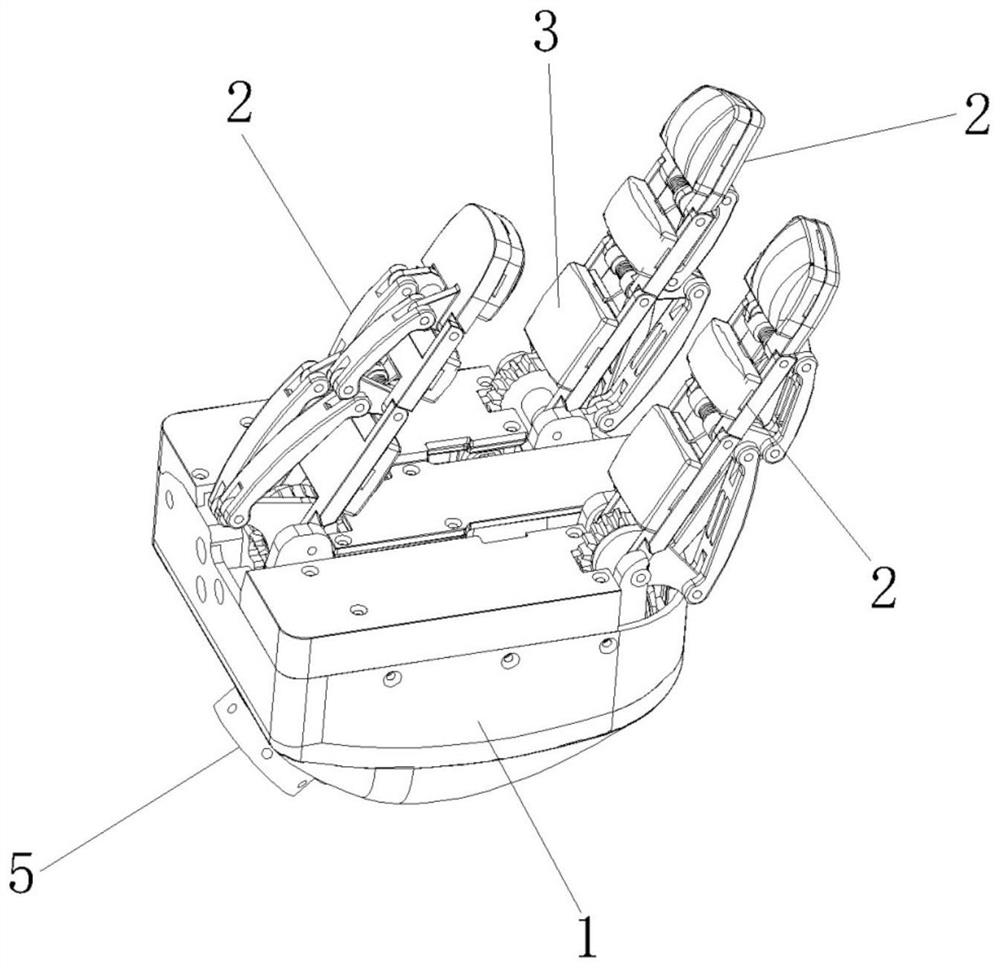

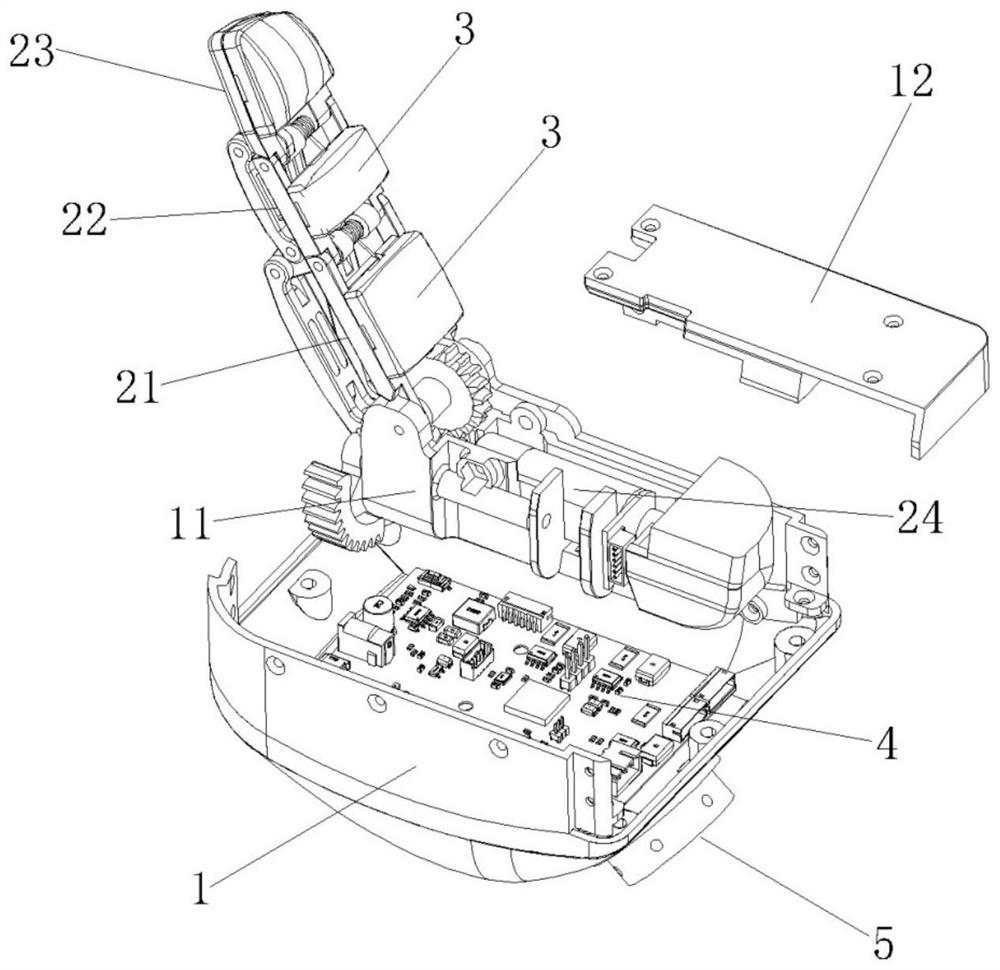

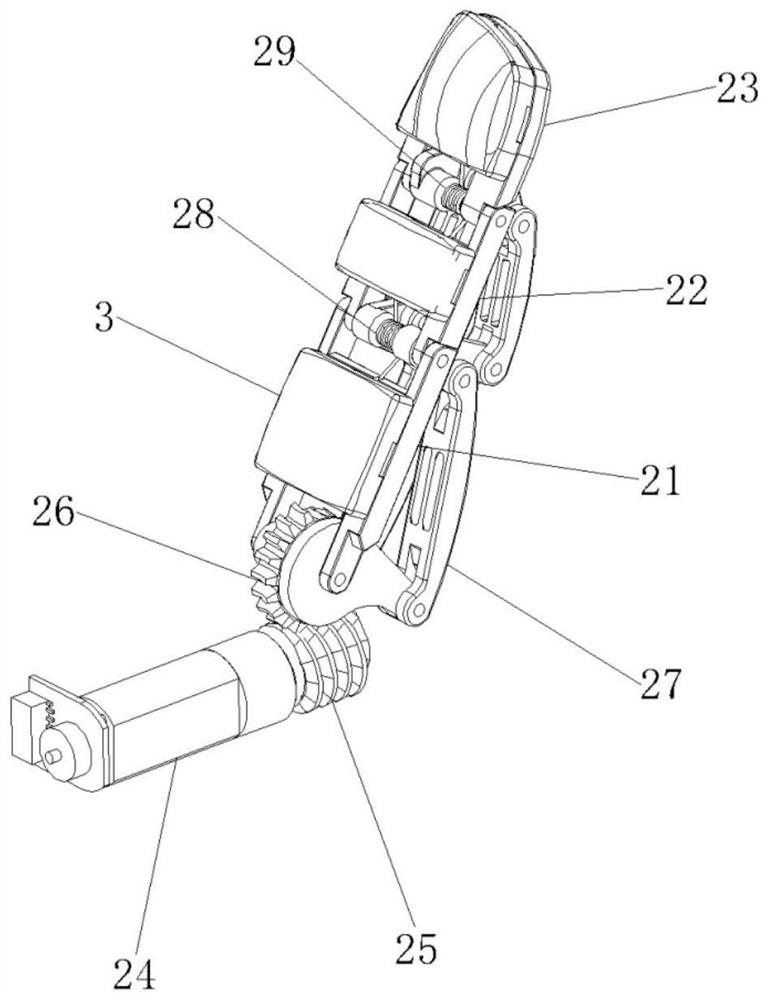

[0026] like Figure 1 to 3 As shown, the embodiment of the present invention provides a full-to-haptical manipulator including the palm 1 and three fingers 2 provided on the palm 1, and the finger 2 includes a finger root 21, refers to 22 and fingertips 23 and a drive device. The root 21 is riveted with the palm 1 through the first axis (not shown), and the middle 22 is riveted by the second a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com