Bridge concrete mixing equipment

A technology for mixing equipment and concrete, which is applied to clay preparation devices, cement mixing devices, cleaning methods and tools, etc. It can solve the problems of accelerated dust inhalation by construction workers, troublesome operation, and bulky volume, and achieve the goal of reducing dust inhalation and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

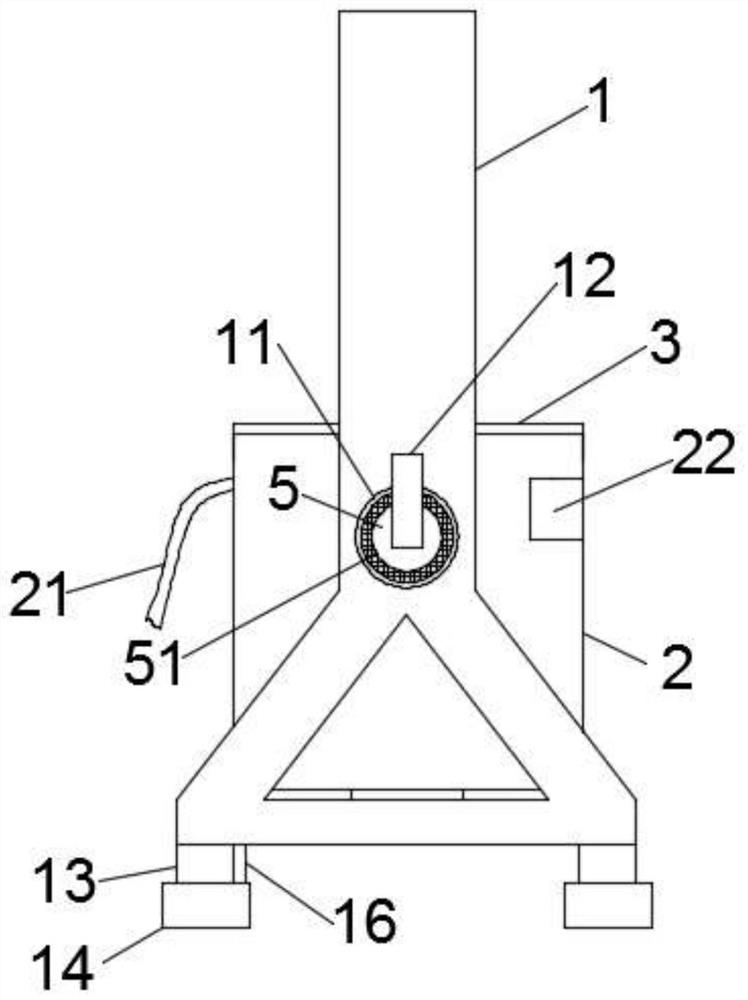

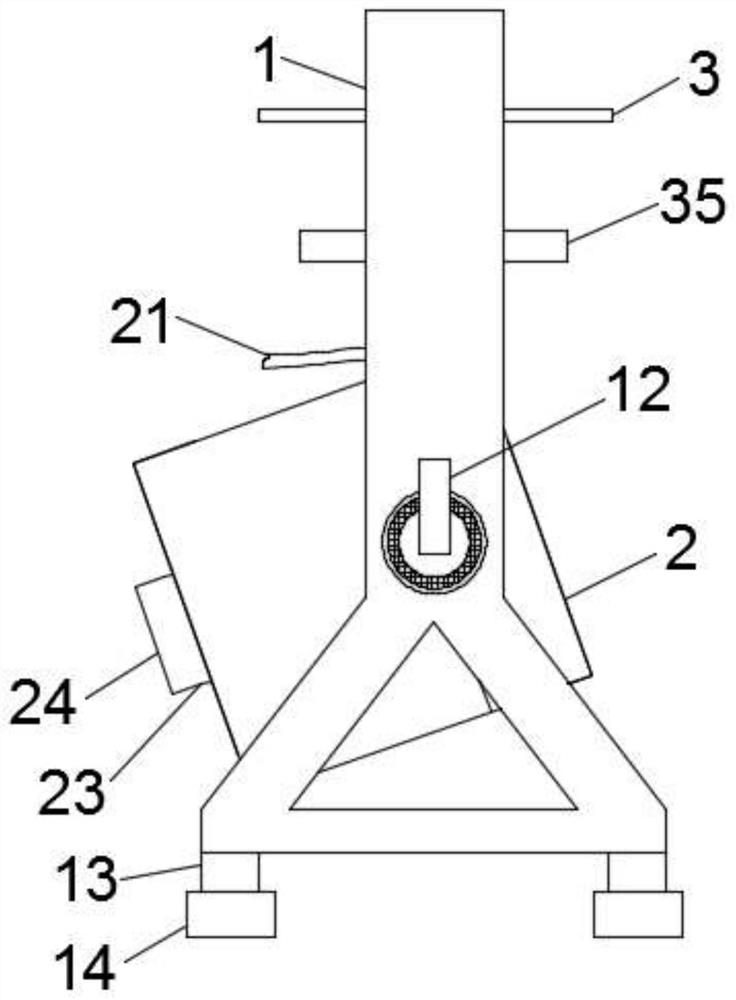

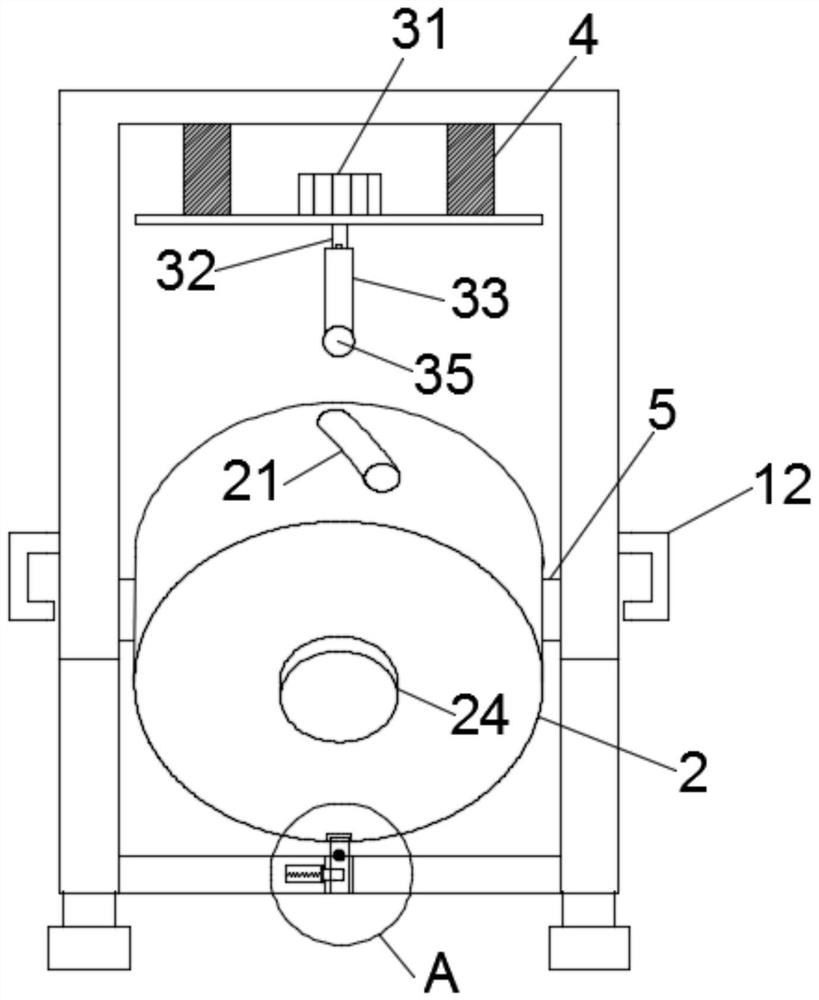

[0031] see Figure 1 to Figure 4 , the present invention provides a technical solution: a concrete mixing equipment for bridges, including a mixing tank and a support frame 1, the mixing tank includes a tank body 2 and a cover body 3, and the left and right ends of the tank body 2 are connected to the support frame through connecting columns 5 1 connection, the tank body 2 is provided with a water injection pipe 21, an observation window 22, a bottom outlet 23, an outlet cover 24 and a receiving hole 25, the outlet cover 24 is screwed to the bottom outlet 23, and the support frame 1 is connected to the receiving hole 25 through a positioning rod 16 , the cover body 3 is connected with the support frame 1 through two sets of symmetrical vertical electric telescopic rods 4, the cover body 3 is equipped with a stirring motor 31 and a stirring shaft, the output end of the stirring motor 31 is connected with the stirring shaft, and the stirring shaft is fixedly connected with a stir...

Embodiment 2

[0037] see Figure 1 to Figure 5 , the present invention provides a technical solution: a concrete mixing equipment for bridges, including a mixing tank and a support frame 1, the mixing tank includes a tank body 2 and a cover body 3, and the left and right ends of the tank body 2 are connected to the support frame through connecting columns 5 1 connection, the tank body 2 is provided with a water injection pipe 21, an observation window 22, a bottom outlet 23, an outlet cover 24 and a receiving hole 25, the outlet cover 24 is screwed to the bottom outlet 23, and the support frame 1 is connected to the receiving hole 25 through a positioning rod 16 , the cover body 3 is connected with the support frame 1 through two sets of symmetrical vertical electric telescopic rods 4, the cover body 3 is equipped with a stirring motor 31 and a stirring shaft, the output end of the stirring motor 31 is connected with the stirring shaft, and the stirring shaft is fixedly connected with a stir...

Embodiment 3

[0041] see Figure 1 to Figure 9 , the present invention provides a technical solution: a concrete mixing equipment for bridges, including a mixing tank and a support frame 1, the mixing tank includes a tank body 2 and a cover body 3, and the left and right ends of the tank body 2 are connected to the support frame through connecting columns 5 1 connection, the tank body 2 is provided with a water injection pipe 21, an observation window 22, a bottom outlet 23, an outlet cover 24 and a receiving hole 25, the outlet cover 24 is screwed to the bottom outlet 23, and the support frame 1 is connected to the receiving hole 25 through a positioning rod 16 , the cover body 3 is connected with the support frame 1 through two sets of symmetrical vertical electric telescopic rods 4, the cover body 3 is equipped with a stirring motor 31 and a stirring shaft, the output end of the stirring motor 31 is connected with the stirring shaft, and the stirring shaft is fixedly connected with a stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com