Front end opening and closing mechanism for railway vehicle

A technology for a rail vehicle and an opening and closing mechanism, which is applied in the field of rail vehicles, can solve the problems of poor flexibility and inconvenient use of the opening and closing mechanism, and achieves the effects of a reasonable segmentation method, convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

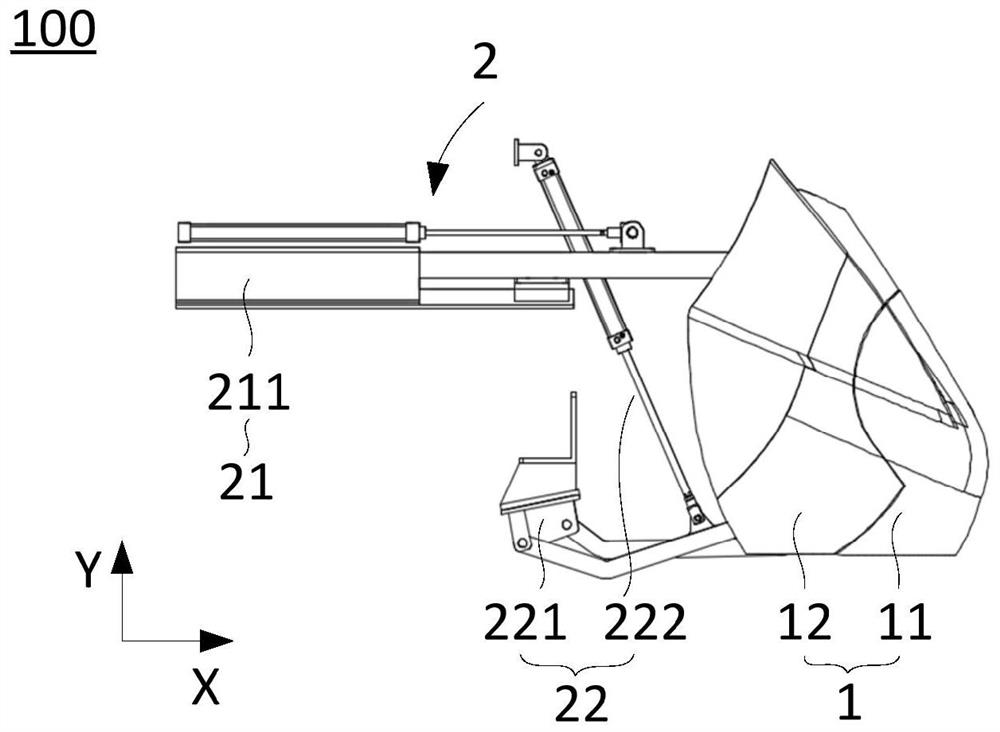

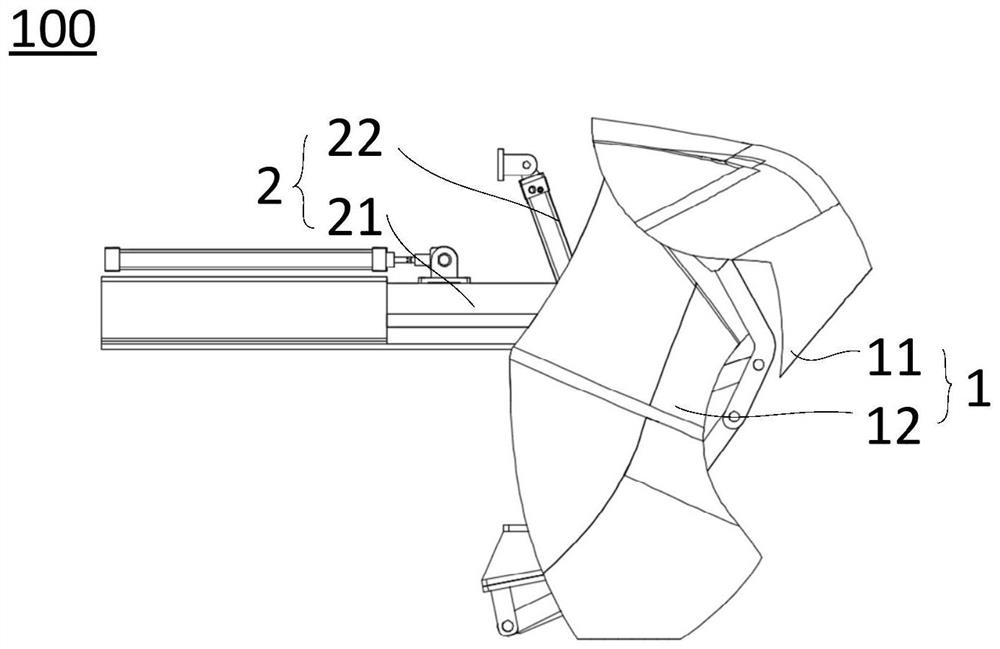

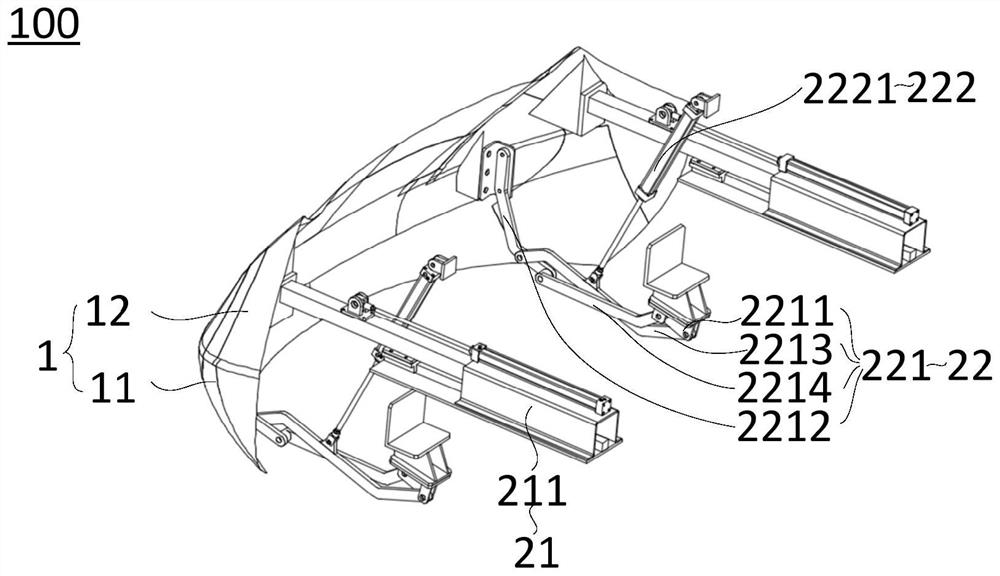

[0033] refer to Figure 1-5 , the front end opening and closing mechanism 100 includes a vehicle head cover 1 and a driving mechanism 2 . Among them, such as figure 1 and figure 2 As shown, the vehicle head cover 1 includes a direction along the extension of the rail vehicle (for example figure 1 The front cover 11 and the rear cover 12 that are arranged front and rear in the direction shown by X in the middle. The drive mechanism 2 is connected between the vehicle head cover 1 and the rail vehicle body, and is used to drive the front cover 11 and the rear cover 12 to close or separate. The drive mechanism 2 includes a translation assembly 21 and a rotation assembly 22. The translation assembly 21 is connected to the front cover One of the front cover 11 and the rear cover 12 is used to drive it to translate, and the rotating assembly 22 is connected to the other one of the front cover 11 and the rear cover 12 and used to drive it to rotate.

[0034] The above-mentioned f...

Embodiment 2

[0058] Similar to the first embodiment, the front opening and closing mechanism 100 includes a vehicle head cover 1 and a driving mechanism 2 . The driving mechanism 2 is connected between the vehicle head cover 1 and the rail vehicle body, and is used to drive the front cover 11 and the rear cover 12 to close or separate. The driving mechanism 2 includes a translation assembly 21 and a rotation assembly 22 .

[0059] In this example, if Figure 6 As shown, the translation assembly 21 includes a first linear drive member 211, a first transmission rod 212 and a second transmission rod 213, the first linear drive member 211 includes a main body part 2111 and a movable part 2112 movably connected to the main body part 2111, The main body part 2111 can drive the movable part 2112 to move linearly along the preset direction. There is an angle between the preset direction and the horizontal direction. One end of the first transmission rod 212 is rotatably connected to the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com