Method for rapidly switching multi-stage centrifugal low-temperature liquid pump of air separation device

A fast-switching, low-temperature liquid technology, applied in the chemical industry, can solve the problems of tripping risks, difficult operation, system fluctuations, etc., to avoid the risk of tripping, ensure continuous supply, and reduce disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

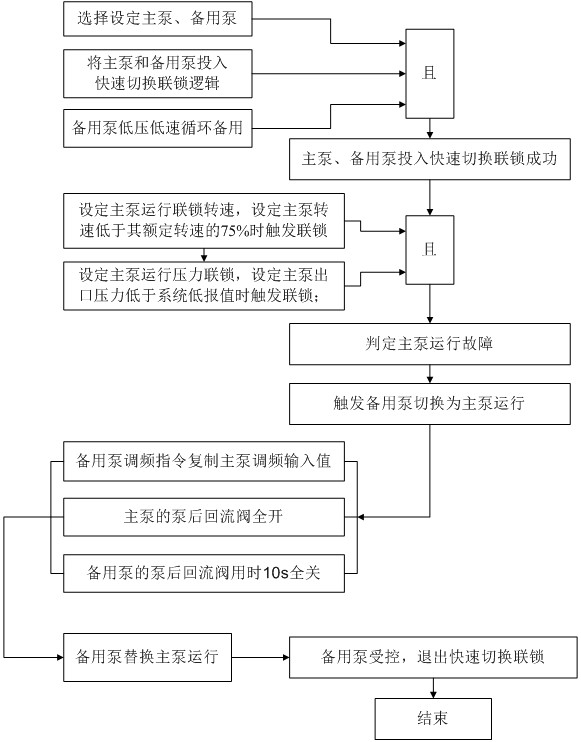

[0025] The air separation unit is equipped with two low-temperature liquid pumps for the same medium. During the operation of the air separation unit, one is used as an output pump and operates at a high speed. Low speed is circulated through the return valve for backup.

[0026] Added interlocking logic for fast switching of cryogenic liquid pumps, and added interlocking input buttons and windows next to the two pumps in the system screen. Click the interlock input button next to the spare pump on the system screen, a confirmation window will pop up, click OK, the button turns red to indicate interlock input. The button next to the main pump on the operation screen does not need to be clicked, and it is green.

[0027] If the main pump is abnormally tripped or the pump is manually stopped, the speed will quickly drop to zero, and the pressure behind the pump will quickly drop to the low alarm value. Logically determine the failure of the main pump and trigger a quick switch....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com