Positioning tool for detecting welding seam defects of air inlet casing and judgment method

A technology of intake casing and positioning tooling, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as difficult to determine welds and small distances between welds, reduce internal stress and deformation, and reduce repair welding times , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

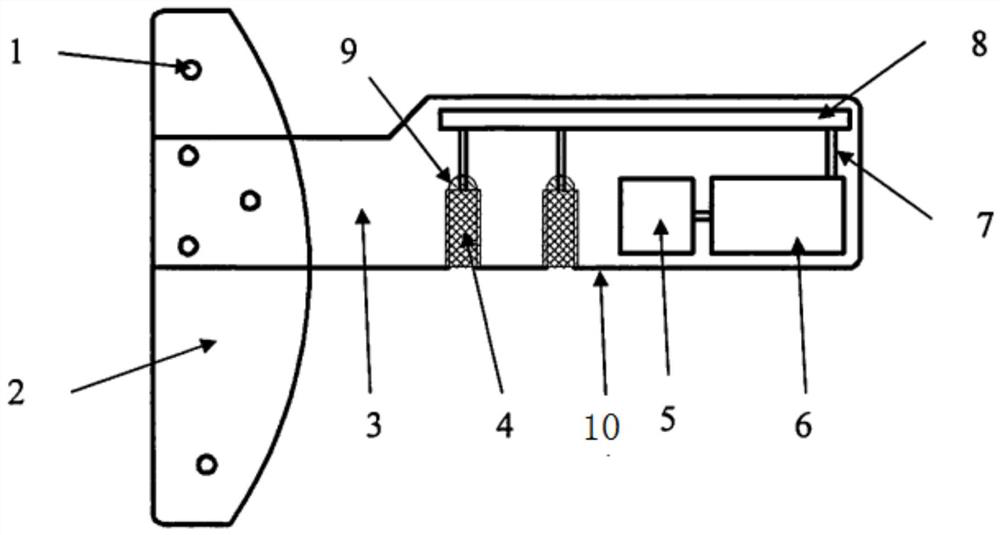

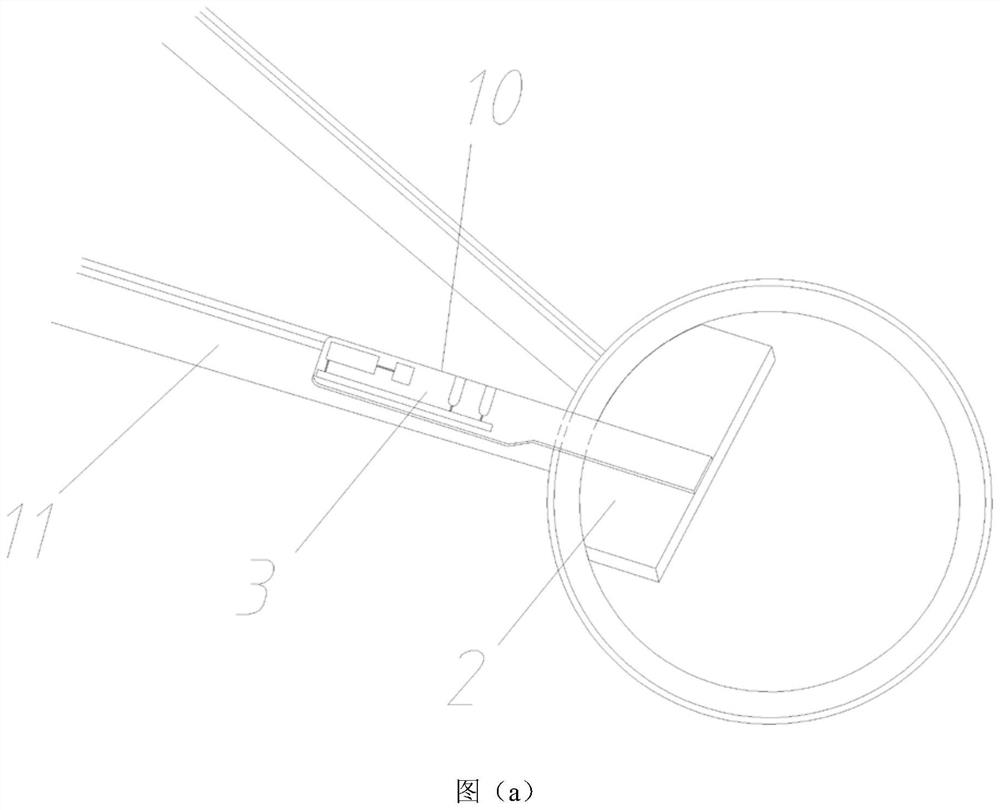

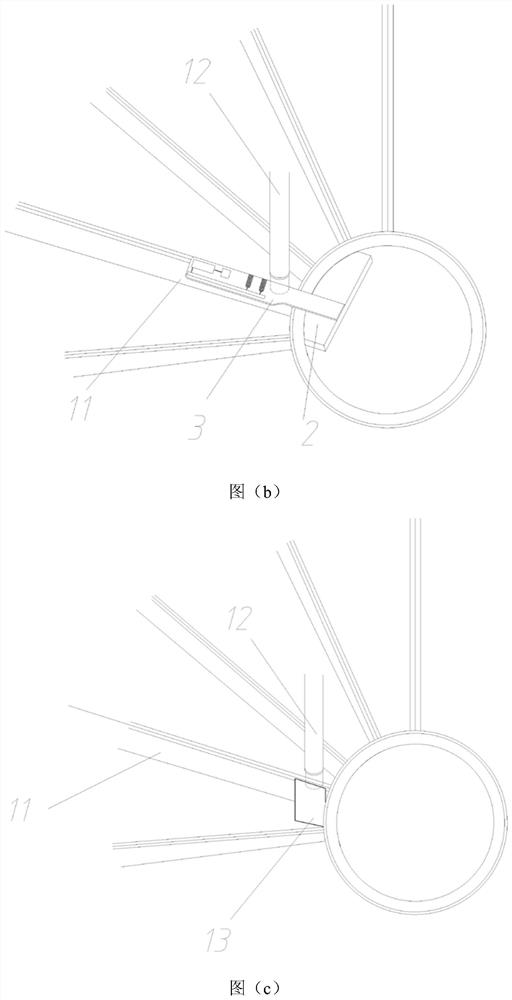

[0023] Such as figure 1 As shown, a positioning tool for detection of weld seam defects in the intake casing, including a fan-shaped support plate 2 and a support plate 3, one side of the fan-shaped support plate 2 is arc-shaped, and the arc-shaped end of the fan-shaped support plate 2 is connected to the inlet The inner arc of the inner ring of the air casing is closely attached, and the fan-shaped support plate 2 is a multi-layer sheet structure, which is assembled with multi-layer pins 1 according to the needs of actual parts, so as to facilitate matching with the inner circle of the inner ring of the air intake casing . In order to increase the thickness without increasing the weight, several gaskets are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com