VR Lens stray light noise detection and calculation method

A calculation method and stray light technology, applied in the direction of calculation, complex mathematical operation, image data processing, etc., can solve the problems of stray light, low efficiency, untraceable detection process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only a part of the present invention, rather than Full examples.

[0030] The present invention provides a VR Lens stray light noise detection calculation method, including the following steps:

[0031] S1 acquires an image;

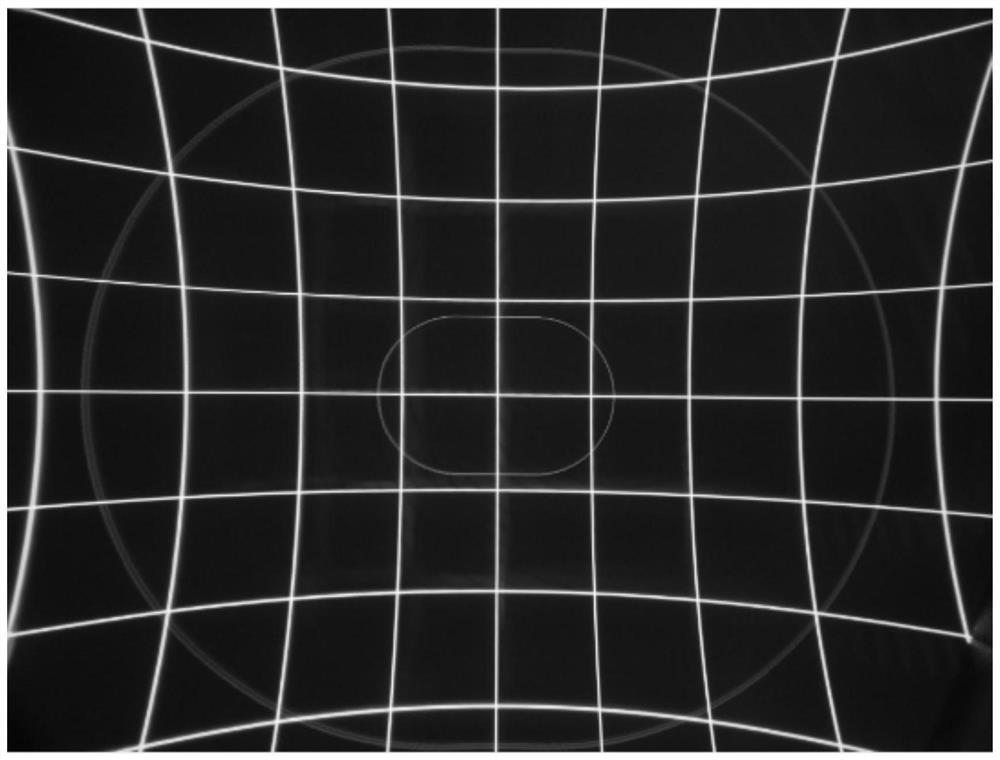

[0032] S2 processes the image to capture astigmatism noise;

[0033] S3 partitions the region where the astigmatism noise is located, calculates the area of each partition, and determines the value of the astigmatism noise according to the area.

[0034] The embodiment of the present invention realizes intelligent detection of VR Lens by effectively analyzing VR images and capturing astigmatism noise. At the same time, in the embodiment of the present invention, by partitioning the area where the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com