Method for automatically assigning handler after reporting abnormal problem

A technology for dealing with people and problems, applied in office automation, data processing applications, instruments, etc., can solve problems such as random contact with handlers, high hardware costs, and lack of specificity, and achieve the effect of reducing invalid waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

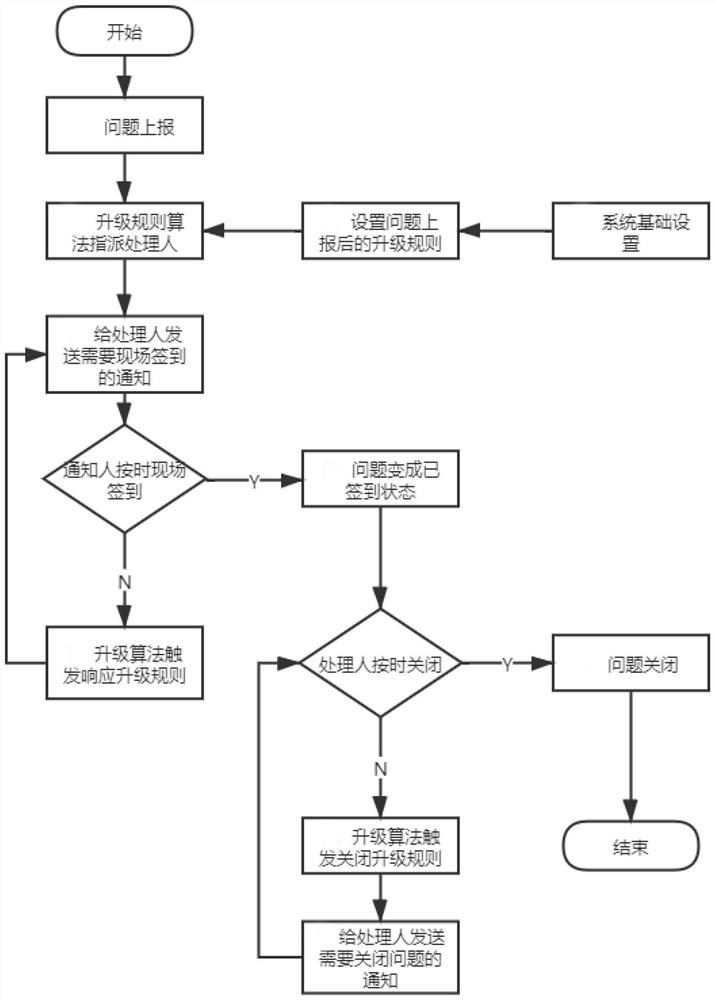

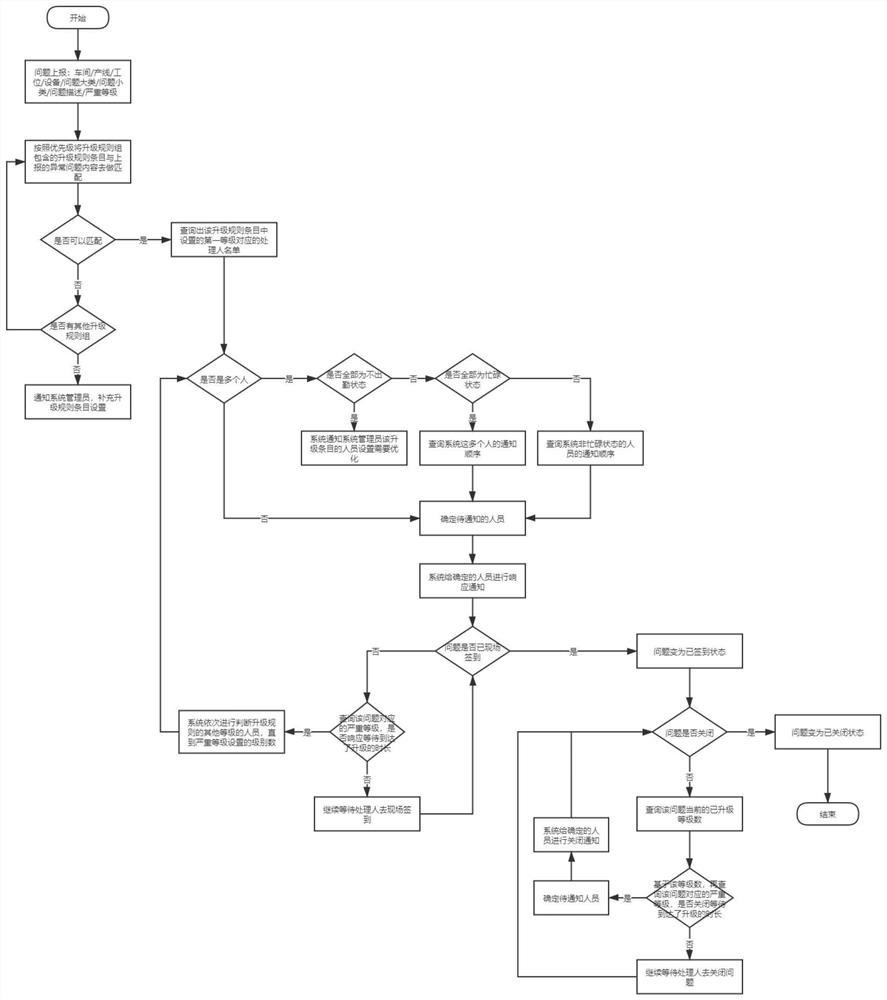

[0062] In a specific embodiment, such as figure 1 and figure 2 As shown, a method for automatically assigning a handler after an abnormal problem in a factory is reported, including the following steps,

[0063] S1: Establish a software system for production abnormal problem management, and perform system basic settings; the basic settings include setting the physical location information of the problem handling site and setting the type of problem. The physical location information includes workshops, production lines, equipment, and workstations; the types of set problems include problem categories, problem subcategories, and problem descriptions.

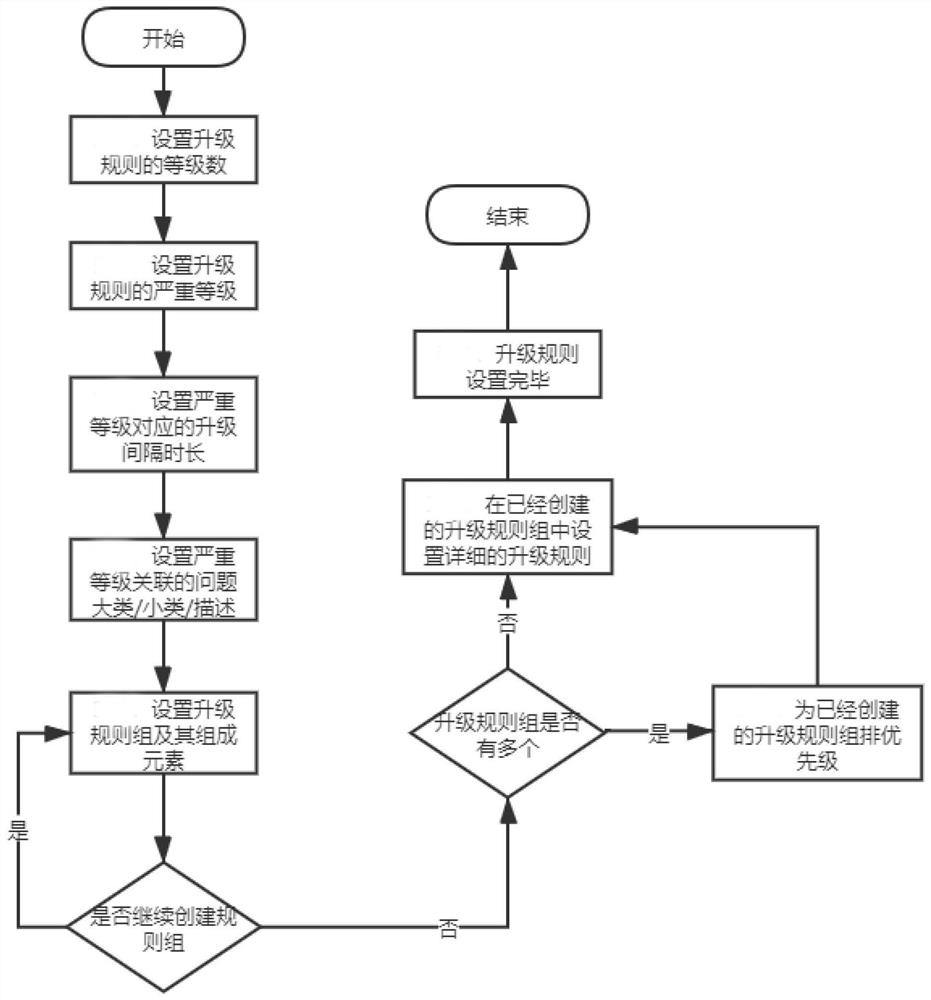

[0064] S2: Set the problem feedback escalation rule algorithm, including the response escalation mechanism. Response refers to the process from reporting a problem to the handler arriving at the site to sign in. Response escalation refers to the problem being reported automatically if no one signs in on site within the required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com