Encoder, motor and driving system

An encoder and code disc technology, applied in the encoder field, can solve the problem of high production cost, improve efficiency, solve the complex process of measuring position information, and simplify complex procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

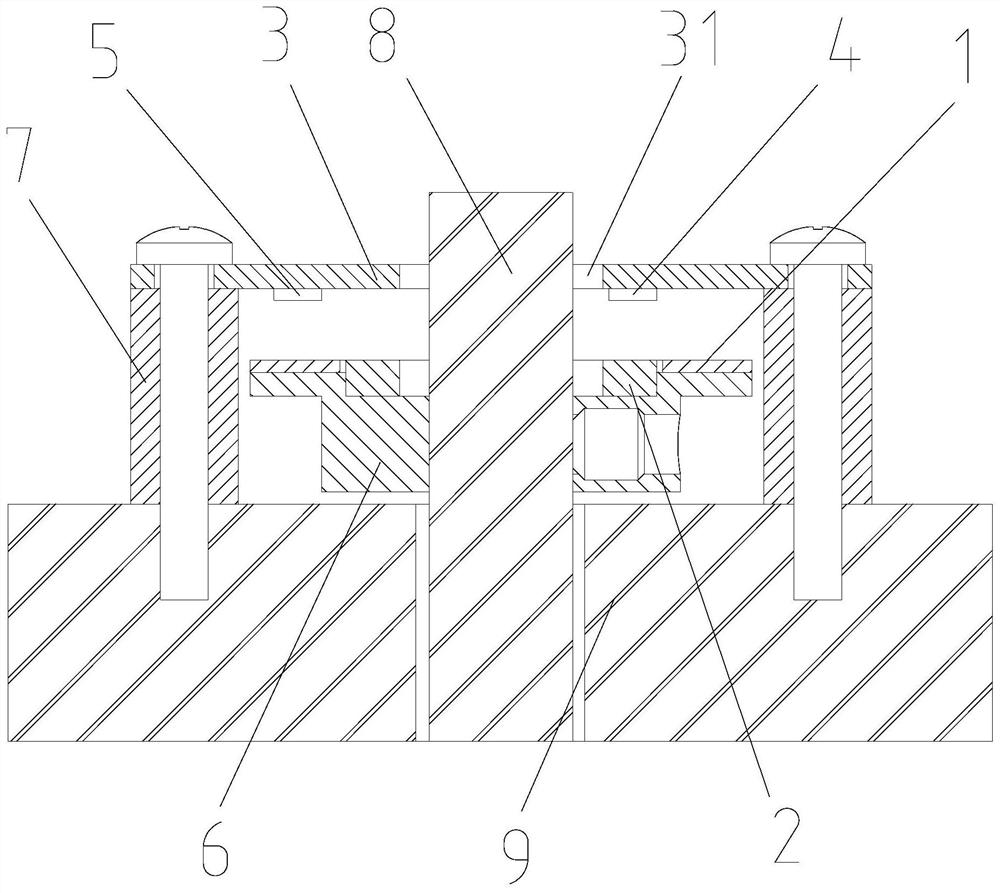

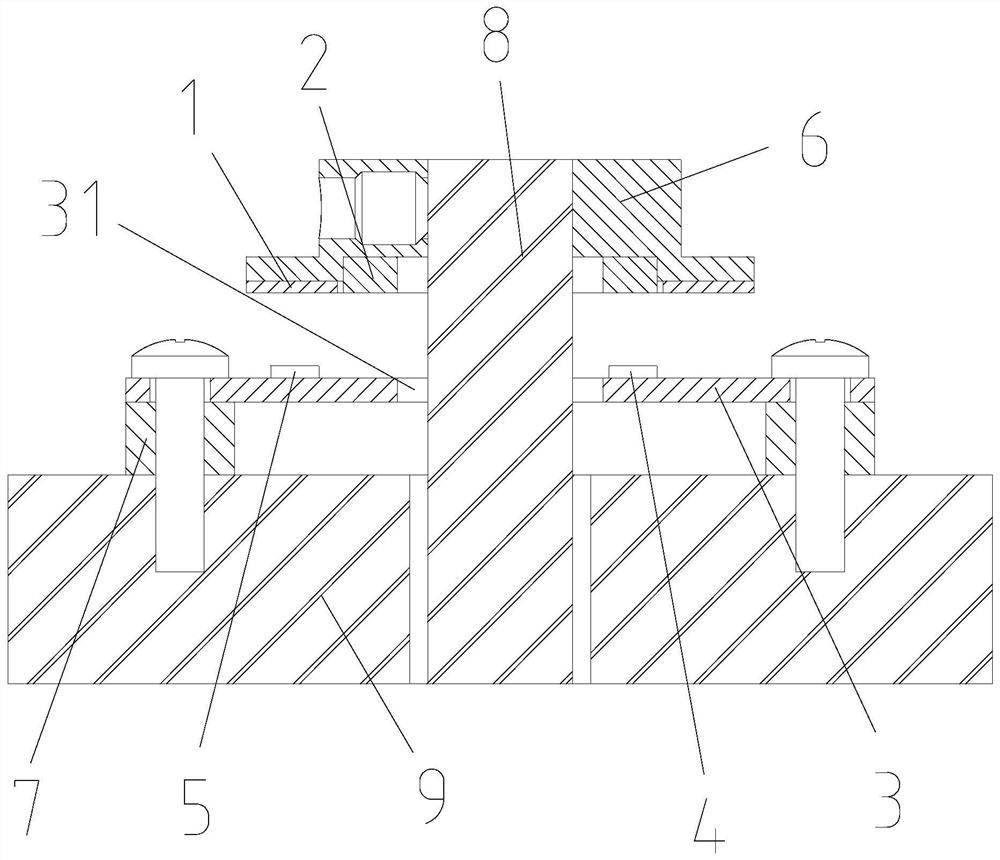

[0040] In the present embodiment, the encoder of the present invention, includes: the code disk 1 and magnet or magnetic ring 2, the code tray 1 and the magnetic steel or magnetic ring 2 are mounted on the rotor of the motor and synchronously with the rotor; circuit board 3 Including at least one magnetic sensing module 4, at least one light sensing module 5, and signal processing module, the magnetic sensing module 4 corresponds to the magnetic steel or magnetic ring 2, the light sensing module 5 is set corresponding to the code disk 1; wherein the encoder is also Including the encoder base 9, the encoder base 9 is mounted on the rear end cover of the motor, and the circuit board 3 is fixed to at least one first mounting portion provided on the encoder base 9.

Embodiment 2

[0042] This embodiment differs from the embodiment of the embodiment in the mounting position of the circuit board 3, in the present embodiment, the encoder of the present invention, including: code disc 1 and magnetic steel or magnetic ring 2, code disc 1 and magnet steel Or the magnetic ring 2 is mounted on the rotor of the motor and moves synchronously with the rotor; the circuit board 3 includes at least one magnetic module 4, at least one light sensing module 5 and the signal processing module, magnetic module 4 and magnet or magnetic ring 2 Corresponding setting, the light sensing module 5 is set corresponding to the code disk 1; wherein the encoder further includes a rear end cap, a rear end cap and a rear end cover of the encoder base 9 or the motor, and a rear end cover for the motor. The disk 1, magnet or magnetic ring 2 and the receiving space of the circuit board 3 are fixed to at least one second mounting portion provided on the rear end cover of the encoder.

Embodiment 3

[0044] The difference from the first and seconds of the present embodiment is different from the mounting position of the circuit board 3, in the present embodiment, the encoder of the present invention, including: the code disc 1 and magnetic steel or magnetic ring 2, the code disc 1 and Magnetic steel or magnetic ring 2 is mounted on the rotor of the motor and moves synchronously with the rotor; the circuit board 3 includes at least one magnetic module 4, at least one light sensing module 5 and the signal processing module, magnetic module 4 and magnet or magnetic The ring 2 corresponds to the setting, the light sensing module 5 corresponds to the code disk 1; wherein the encoder is mounted on the rear cover of the motor, and the circuit board 3 is fixed to at least one third mounting portion provided on the rear end cover of the motor. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com