Camera module and imaging control method

A camera module and imaging control technology, which is applied in the field of cameras, can solve problems such as difficulty in achieving expectations in imaging effects, difficulty in miniaturization, and complex structure, and achieve the goals of improving sensory resolution, reducing image quality loss, and improving image sharpness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

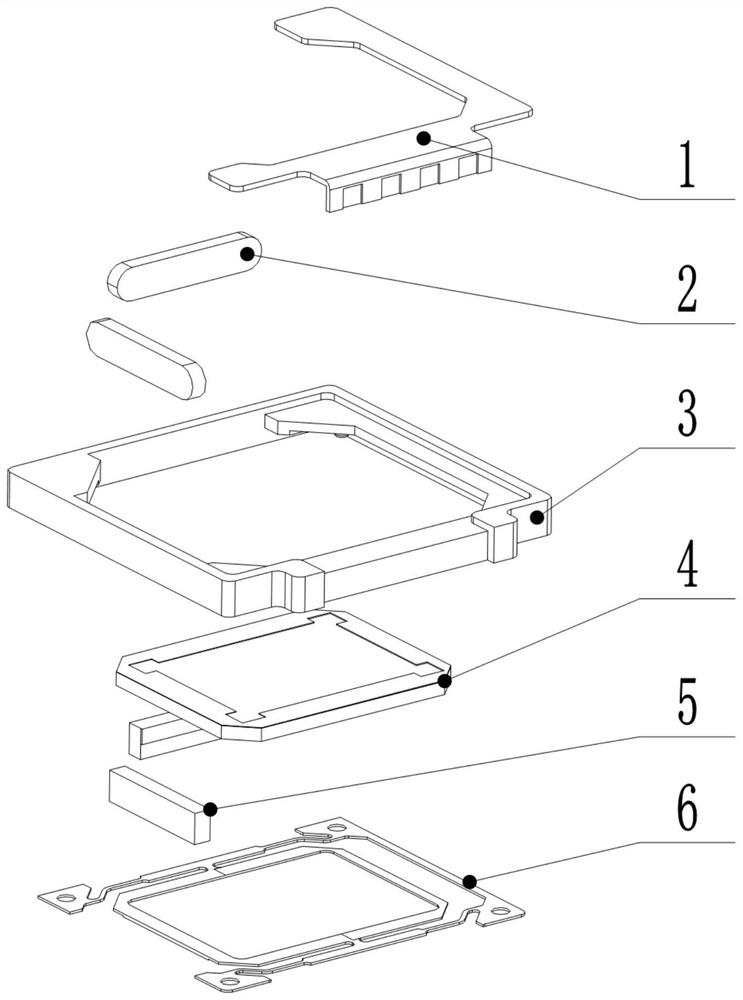

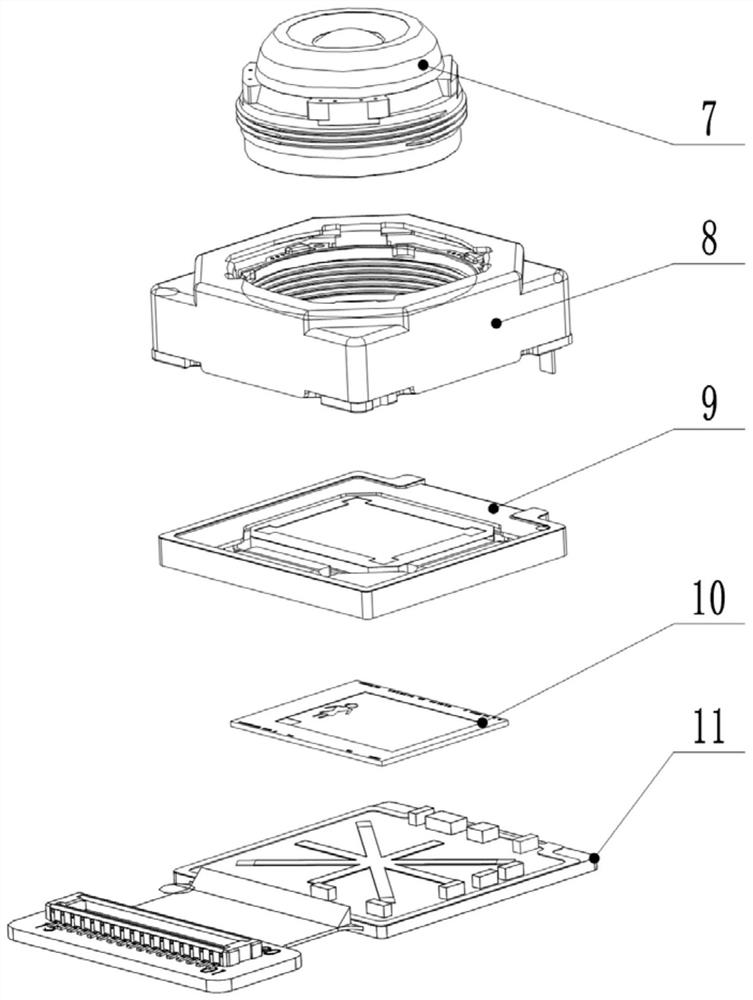

[0035] A camera module, basically figure 1 As shown: including the lens 7, the mirror 8, and the PCBA plate 11 sequentially provided, and a photosensitive chip 10 is provided on the PCBA plate 11. Among them, the photosensitive chip 10 on the lens 7, the mirror 8, and the PCBA plate 11, and the photosensitive chip 10 on the PCBA plate 11 are conventional setup structures of the existing camera modules, and the scheme is not improved, so the structure is not specifically described.

[0036] like figure 2 As shown, the mirror 8 and the photosensitive chip 10 are also provided with a gammell assembly 9 including a base bracket 3, a filter 4, and an actuating motor that are in the middle of the base bracket 3. Wide slots, the filter 4 is disposed in the pass slot and is paired with the photosensitive chip 10, the actuation motor mounting between the passage side wall and the filter 4 and electrically connects the PCBA plate 11. Used to move the filter 4 toward the specified direction ...

specific Embodiment approach

[0050] Predetermined driving waveform is input to the actuator motor in the first coil and the second coil, and shaking off setting time has elapsed, the time waveform by combining the control to a fixed frequency of 50Hz or 60Hz moved accurately jitter beam few microns, the galvanometer will shake the filter assembly is tilted to a certain angle, to complete the operation set specifies a first operation a, retention time at an angle, to complete the first image frame collected by the light-sensitive chip. Then after setting the switching time of the operation, the waveform changes at a fixed frequency of 50Hz or 60Hz of a few microns moving the beam jitter precisely, the galvanometer will shake the filter assembly is inclined at an angle to the other, to complete the specified action the second set of actions B, retention time at an angle, to complete the second image frame collected by the sensor chip, and then continue the cycle, the third frame image capture, the fourth frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com