Sticky food temperature adjusting machine

A temperature control machine and food technology, applied in the confectionary industry, food science, cocoa, etc., can solve the problems of occupying space, inconvenient use, complicated cleaning process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

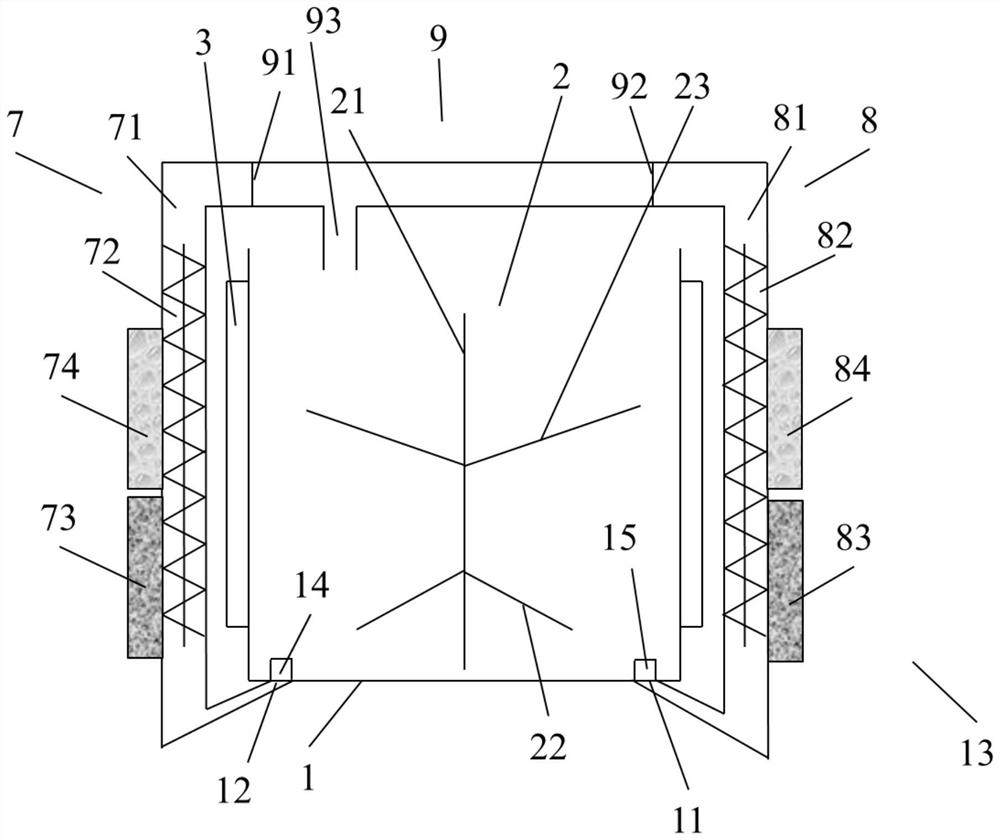

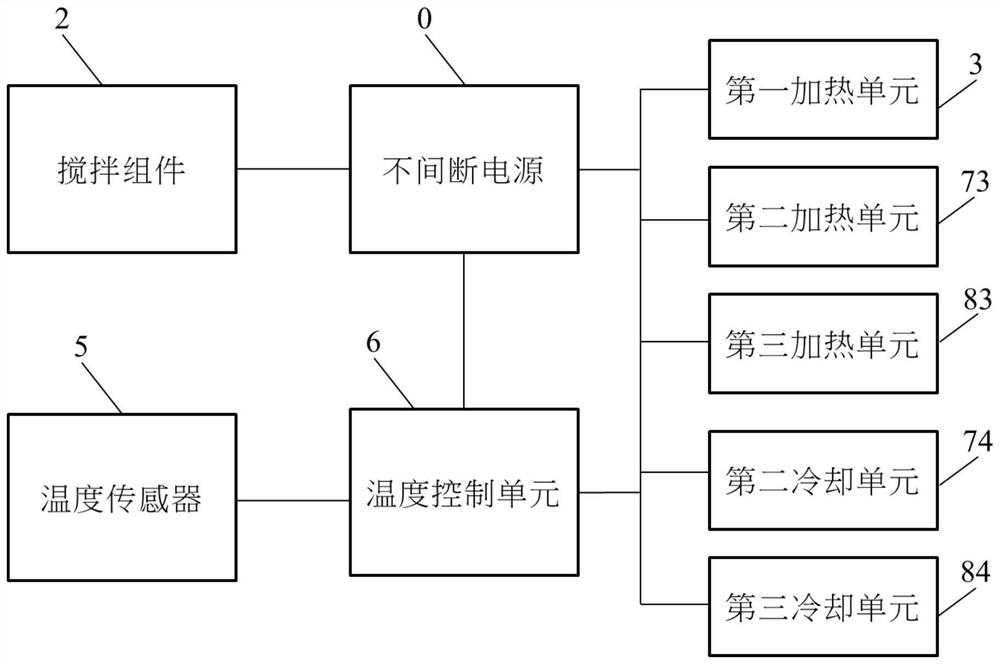

[0057] see figure 1 As shown, the present invention is about a viscous food tempering machine, comprising:

[0058] One container 1:

[0059] The container 1 has a chamber 11 for containing thick food. A stirring assembly 2 is arranged in the chamber 11. The chamber 11 forms an opening on the top surface of the container 1. The container The bottom of the container 1 is provided with a first perforation 12 and a second perforation 13 respectively communicated with the chamber 11, a first plug 14 is operatively provided at the first perforation 12, and a first plug 14 is operatively provided at the second perforation 13. A second plug body 15 is provided; a first heating unit 3 is provided outside the container 1 .

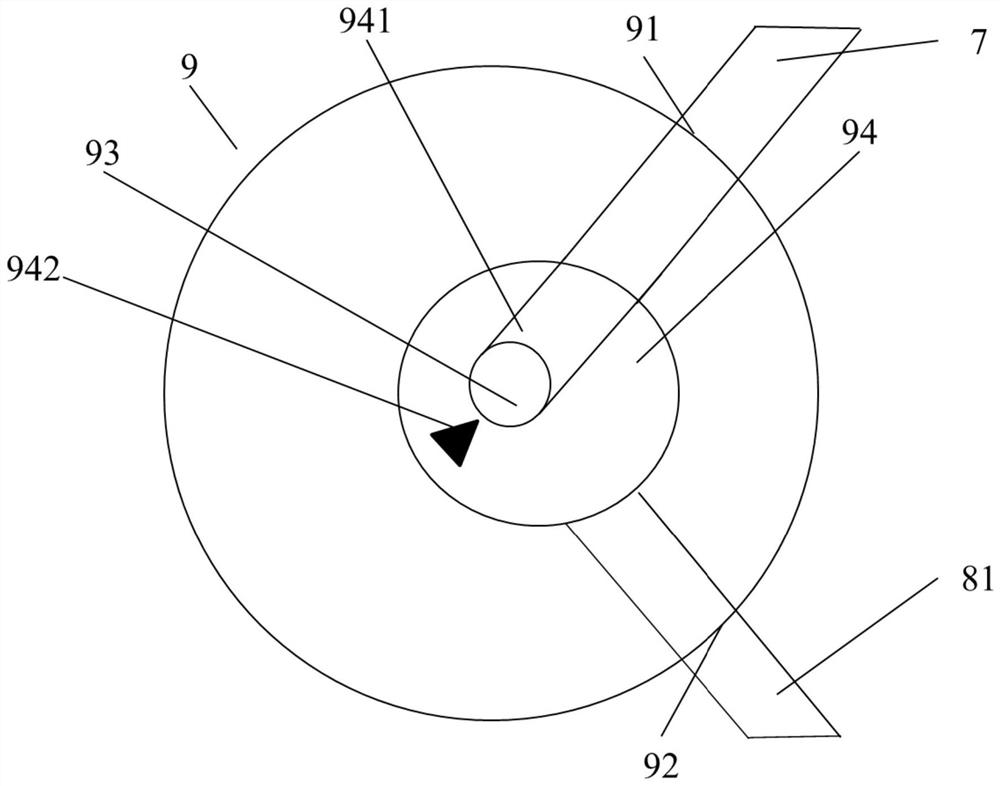

[0060] please cooperate figure 2As shown, in order to improve the temperature adjustment efficiency, the stirring assembly 2 for the temperature adjustment operation preferably includes a rod body 21, and a first fan blade group 22 and a second fan blade group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com