Steam box control method and steam box

A control method and technology of a steam box, which are applied in the steam generation method, timing control ignition mechanism, steam generation and other directions, can solve the problems of low heating efficiency, etc., and achieve the effect of improving the effect, shortening the time, and short the heat conduction distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

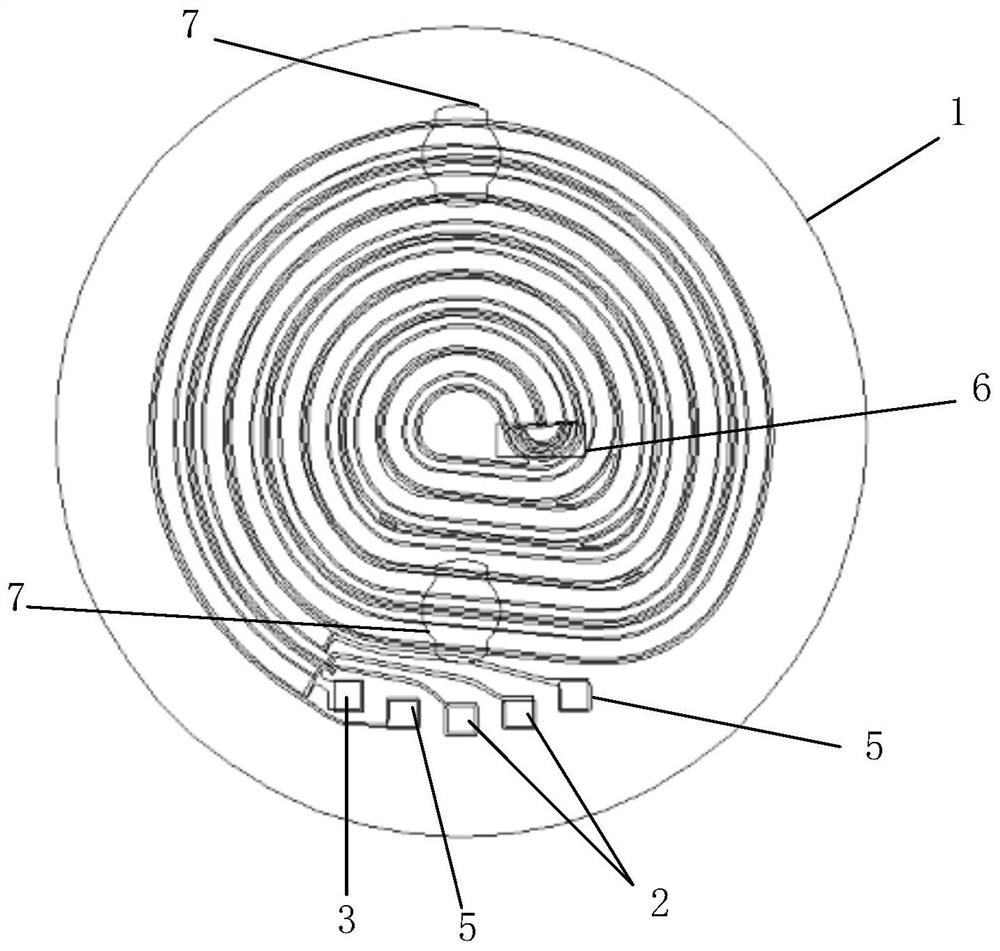

[0051] Such as figure 1 As shown, this embodiment provides a steam generating device for a steam box. The steam generating device includes: a chassis structure 1, and at least one group of thick film heating resistance wires 2 arranged on the chassis structure 1, adjacent thick film heating resistance wires are coiled independently or in parallel, and each group of thick film heating resistance wires The wires are all connected to the same zero line 3; the temperature acquisition unit 4 is in contact with each group of thick film heating resistance wires, and the temperature acquisition unit is used to collect the temperature data of the thick film heating resistance wires.

[0052] Such as figure 2 As shown, in an optional embodiment, the steam generating device includes two sets of thick-film heating resistance wires 2; two sets of thick-film heating resistance wires 2 are coiled and arranged on the chassis structure 1 in parallel.

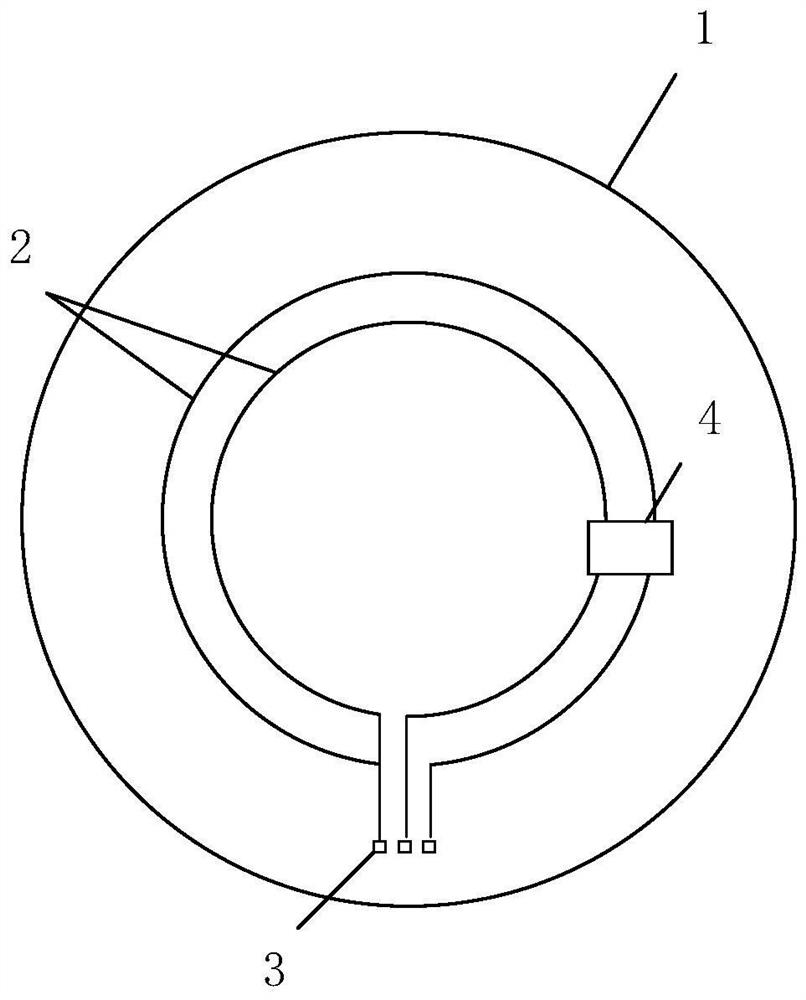

[0053] Such as image 3 As shown, in ...

Embodiment 2

[0090] Such as Figure 7 As shown, this embodiment provides a steam box, including a box body 8 and the steam generating device 9 in embodiment 1 or embodiment 2; the steam control device 9 is arranged inside the box body.

[0091] The steam box can also include other components such as a water tank, a water pump and a water pipe; the water tank and the water pump are arranged outside the casing, the water tank and the water pump are connected to the steam generating device through the water pipe, and the water pump is electrically connected to the controller of the steam generating device; the controller is used for A steam generating unit that controls the water pump to draw water from the tank to the steam generating unit.

[0092] In an optional embodiment, the steam box further includes a display, which is arranged outside the box and is electrically connected to the controller. The controller can send the display information to the display, so that the display can displ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com