Filter residue recycling device for preparing adblue

A technology of urea and filter residue for vehicles, applied in the direction of filtration and separation, fixed filter element filter, separation method, etc., can solve the problems of easy blockage and trouble of filter parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

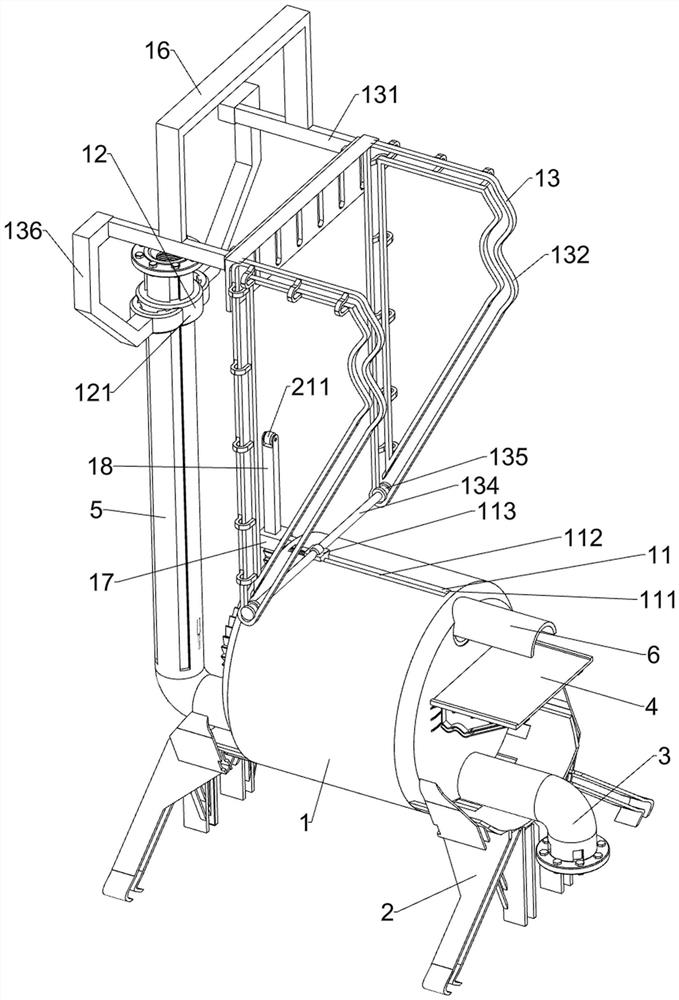

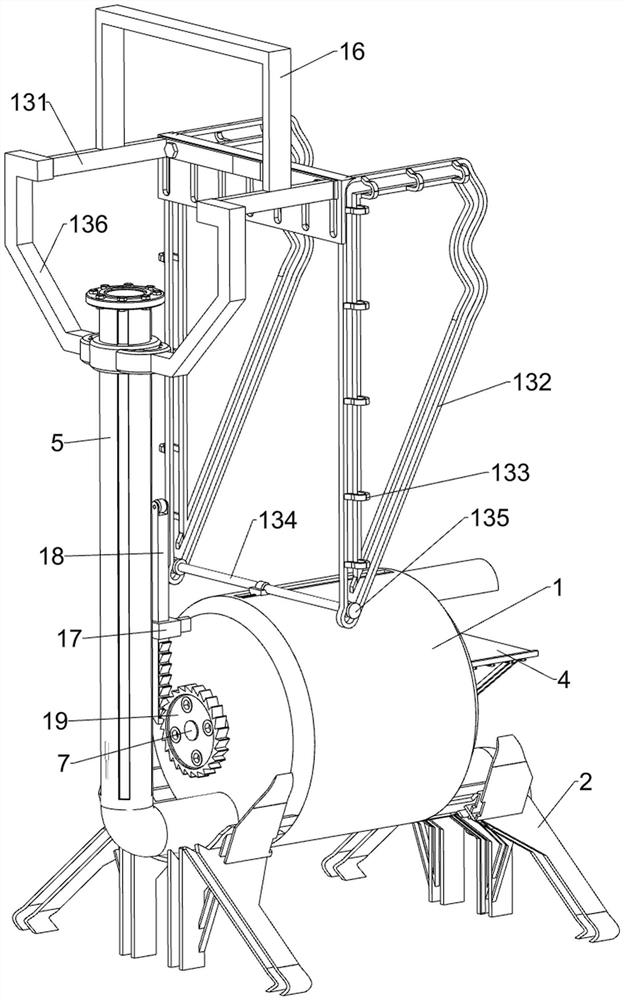

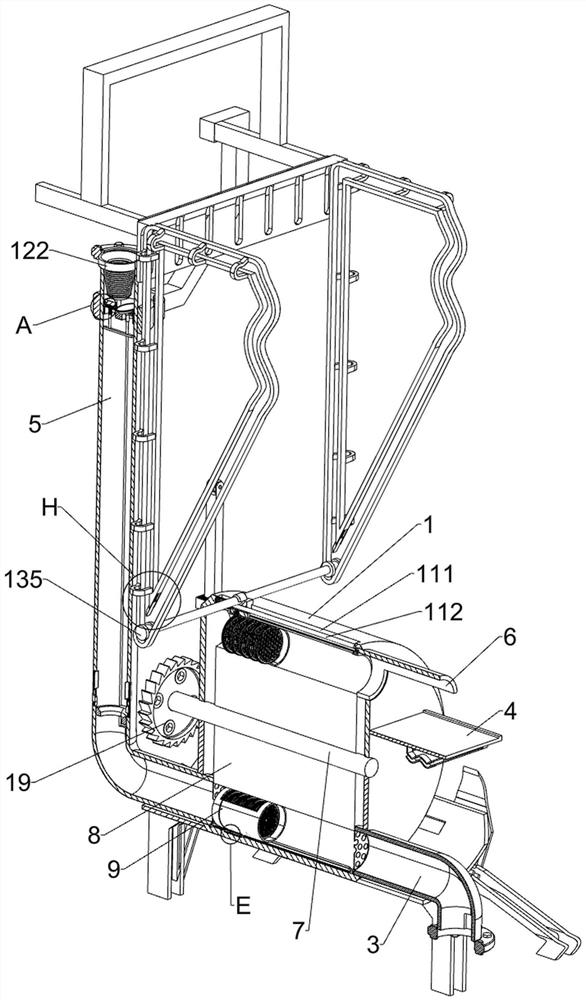

[0036] Embodiment: A kind of recycling filter residue device for the preparation of vehicle urea.

[0037] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 8, Figure 9 , Figure 12 and Figure 13 As shown, it includes a cylinder body 1, a leg 2, a liquid outlet pipe 3, a support plate 4, a liquid inlet pipe 5, an arc plate 6, a first rotating shaft 7, a porous cylinder 8, a hollow pipe 9, a filter screen 10, iron Block 101, driving mechanism 11 and feeding mechanism 12, outriggers 2 are fixedly connected to the lower parts of the left and right sides of the cylinder body 1, a support plate 4 is fixedly connected to the upper middle of the outer right side of the cylinder body 1, and the upper right side of the cylinder body 1 An arc-shaped plate 6 is fixedly connected in the middle, and a first rotating shaft 7 is connected rotationally between the center positions of the left and right sides of the cylinder body 1. The middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com