Constant-power electrothermal regeneration method and device for granular active carbon

A technology of granular activated carbon and constant power, which is applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of unstable electric heating regeneration power, reduced electric heating regeneration efficiency, low power, etc. The effect of stabilizing problems and improving regeneration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

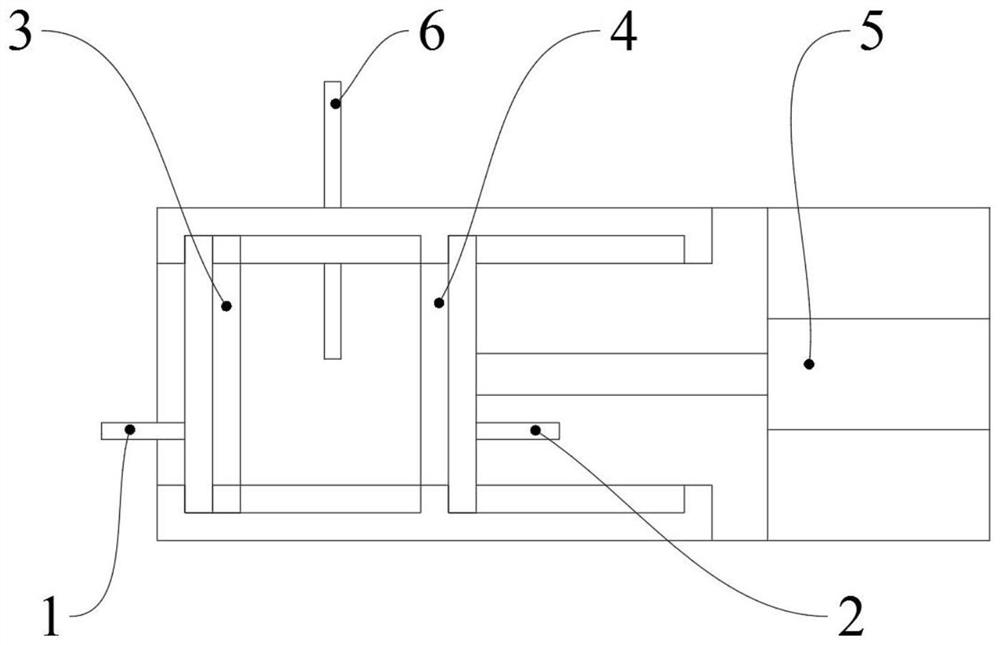

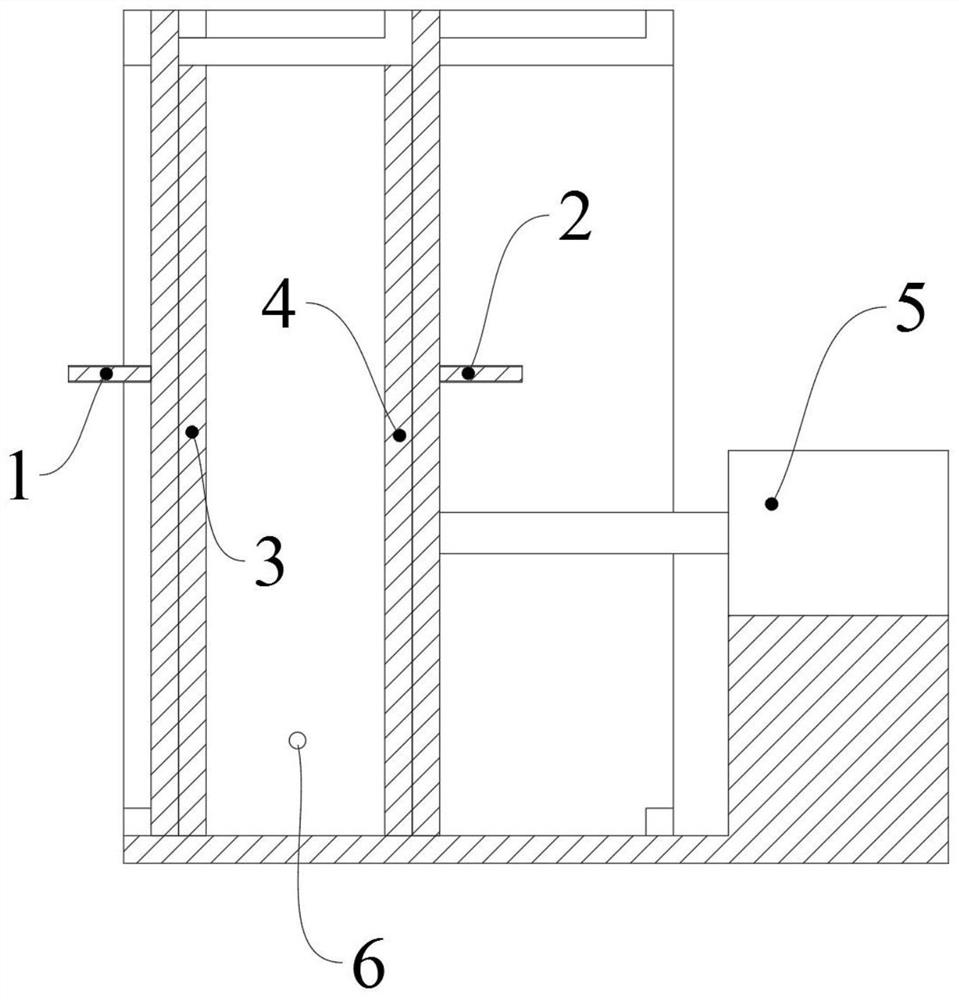

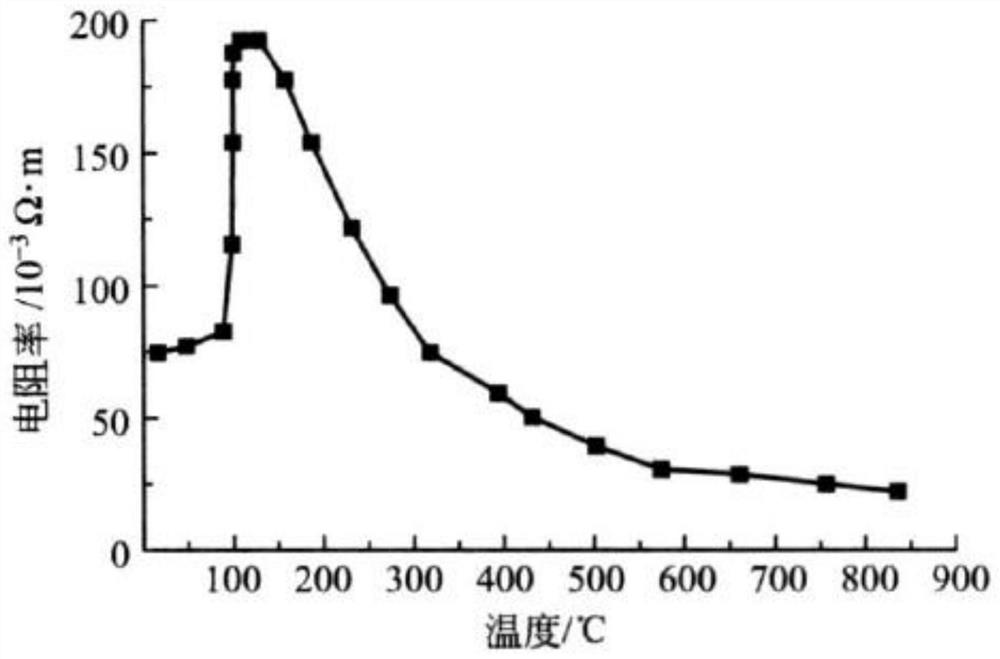

[0024] Such as figure 1 and 2 As shown, an electrothermal regeneration device with constant power of saturated activated carbon includes a first electrode plate 3, a second electrode plate 4, a cylinder 5, a temperature sensor 6, a display and a power supply box. The base and the track plate are made of high-temperature-resistant materials (specifically, they can be used continuously in an environment of 900°C). The first electrode plate 3 and two track plates are fixed on the base. The first electrode plate 3 is located at the same end of the two track plates. The second electrode plate 4 is slidingly connected with the two track plates, and is located between the two track plates. The base, the first electrode plate 3, the second electrode plate 4 and two track plates form a regenerative chamber with an open top and closed other positions. By sliding and adjusting the position of the second electrode plate 4, the length of the regeneration chamber can be dynamically adju...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that in the process of electrothermal regeneration, the magnitude of the input voltage U is detected in real time, and the electrothermal regeneration power P=UI is calculated; where, I is the input current; when the electrothermal regeneration power P increases , the cylinder drives the second electrode plate 4 to move close to the first electrode plate 3, reducing the overall resistance of the granular activated carbon; when the electrothermal regeneration power P decreases, the cylinder drives the second electrode plate 4 to move away from the first electrode plate 3, increasing the particle size The resistance of the activated carbon as a whole; so that the electric heating regeneration power P remains constant.

[0034] At the same time, the display shows the input current and input voltage of electrothermal regeneration in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com