Equipment for treating scaling powder on surface of preformed soldering lug

A technology for solder preforms and processing equipment, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of affecting welding quality, inconsistent flow speed of soldering sheets, and a large number of fine particles in welding parts, so as to improve the accuracy of dosage sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

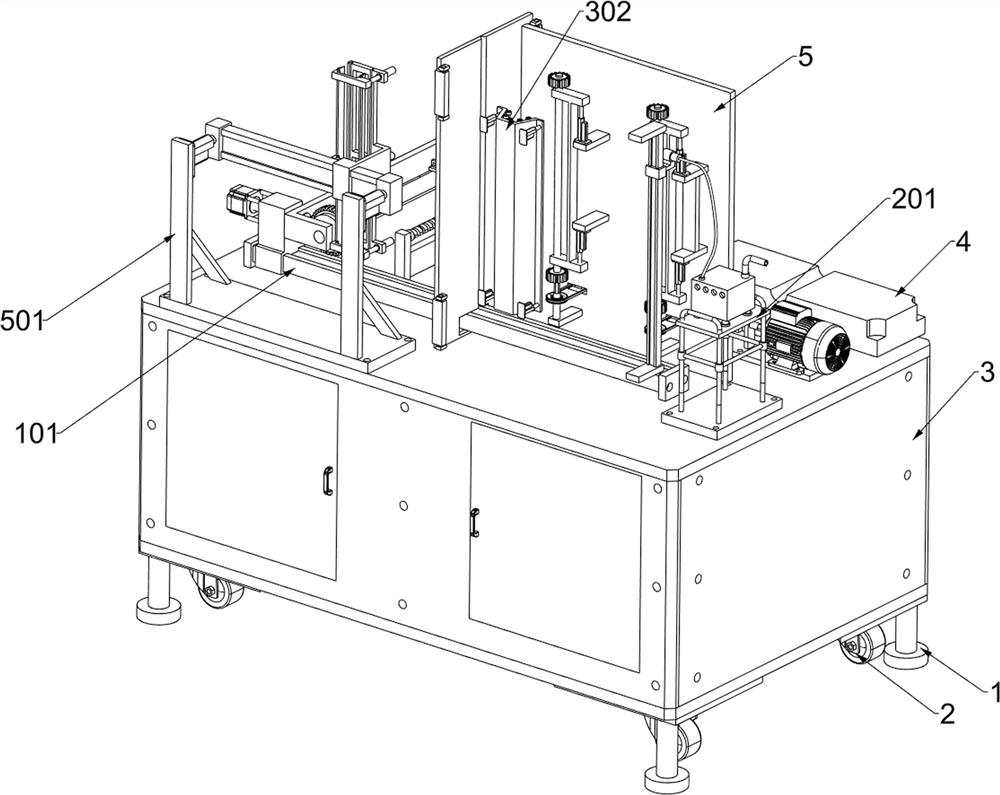

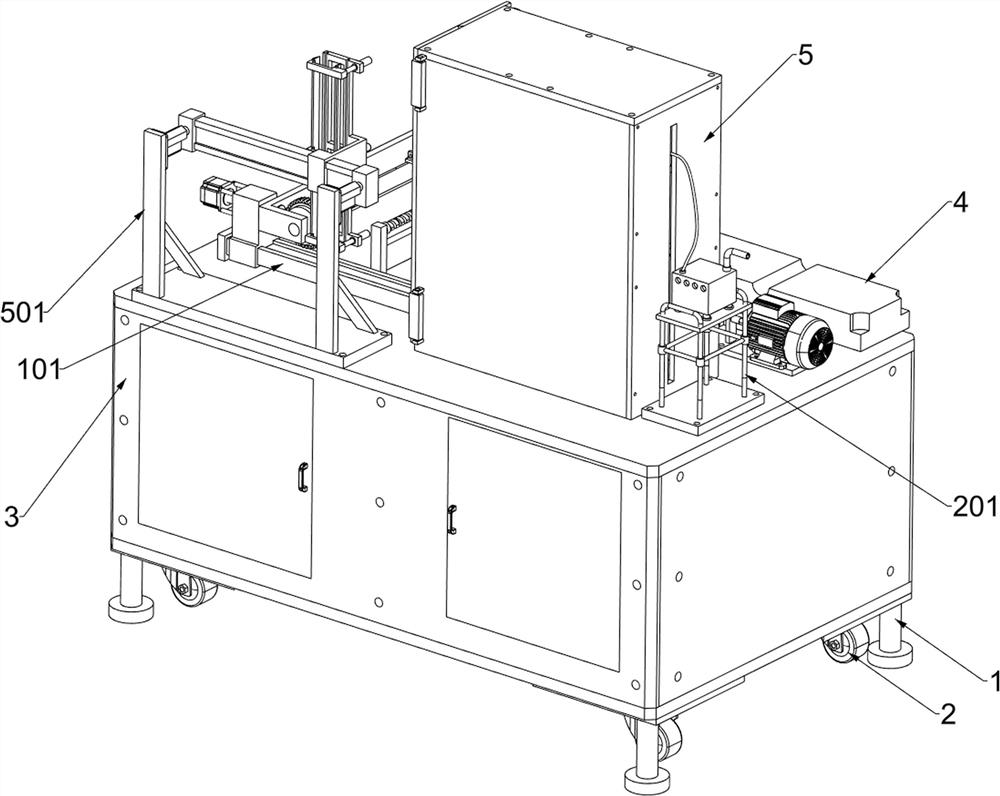

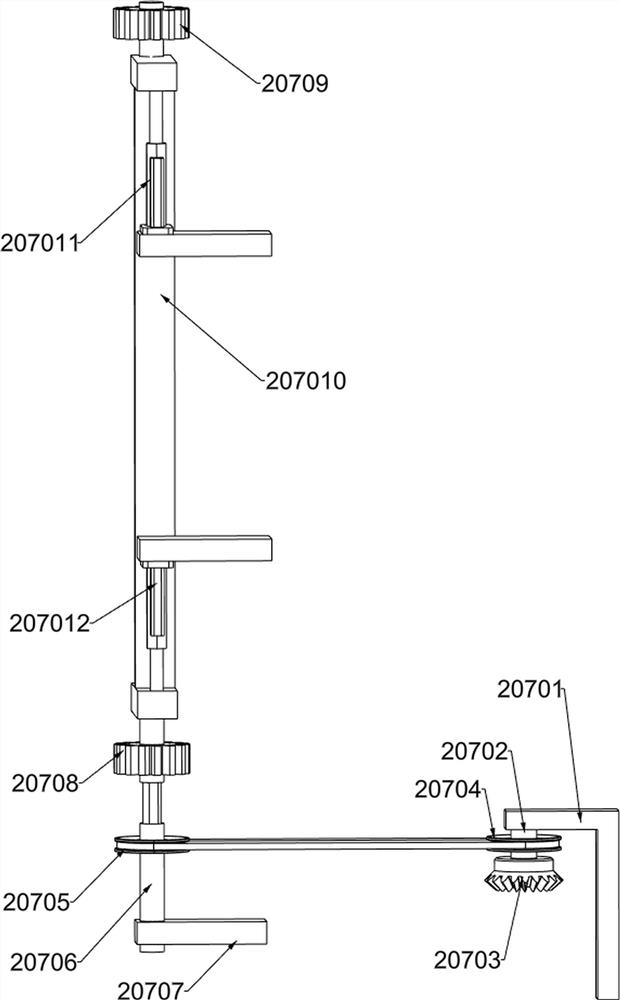

[0037] A preform surface flux processing equipment, according to Figure 1-3 As shown, it includes support column 1, wheel 2, frame 3, battery 4, casing 5, surface finishing system and cutting system; four corners below the frame 3 are respectively provided with a group of support columns 1; the bottom of the frame 3 is provided with Four sets of wheels 2; a battery 4 is installed on the left front side above the frame 3; a casing 5 is installed on the left middle above the frame 3; a cutting system for removing excess scraps from the processed solder pieces is installed on the right rear side above the frame 3; A surface finishing system for treating the surface of the welding sheet is installed on the front side above the frame 3; the surface finishing system is located at the front side of the cutting system.

[0038] Working process: Before the device is running, move the device to a stable working place, then adjust the height of the four sets of support columns 1, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com