A cold press for the production of technical veneers that facilitates stacking and aligning veneers

A technical veneer and cold press technology, applied in the field of cold press, can solve the problems of reducing friction, affecting work efficiency, affecting work quality, etc., and achieve the effect of facilitating quick disassembly, improving work efficiency, and improving work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

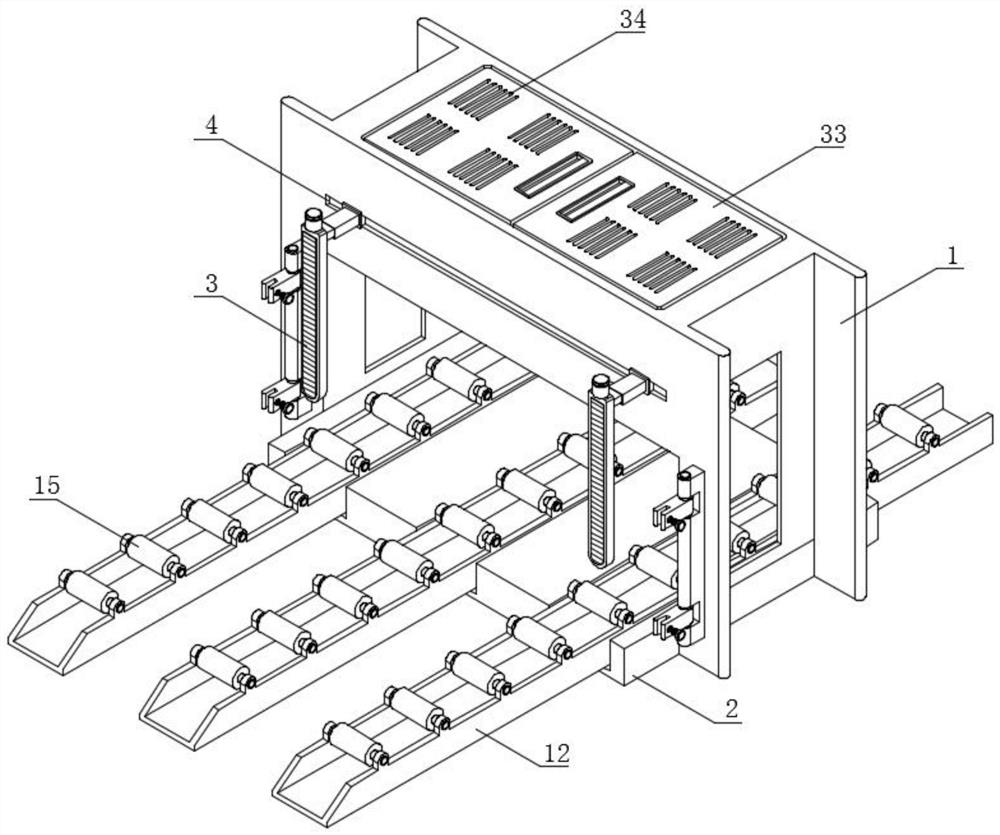

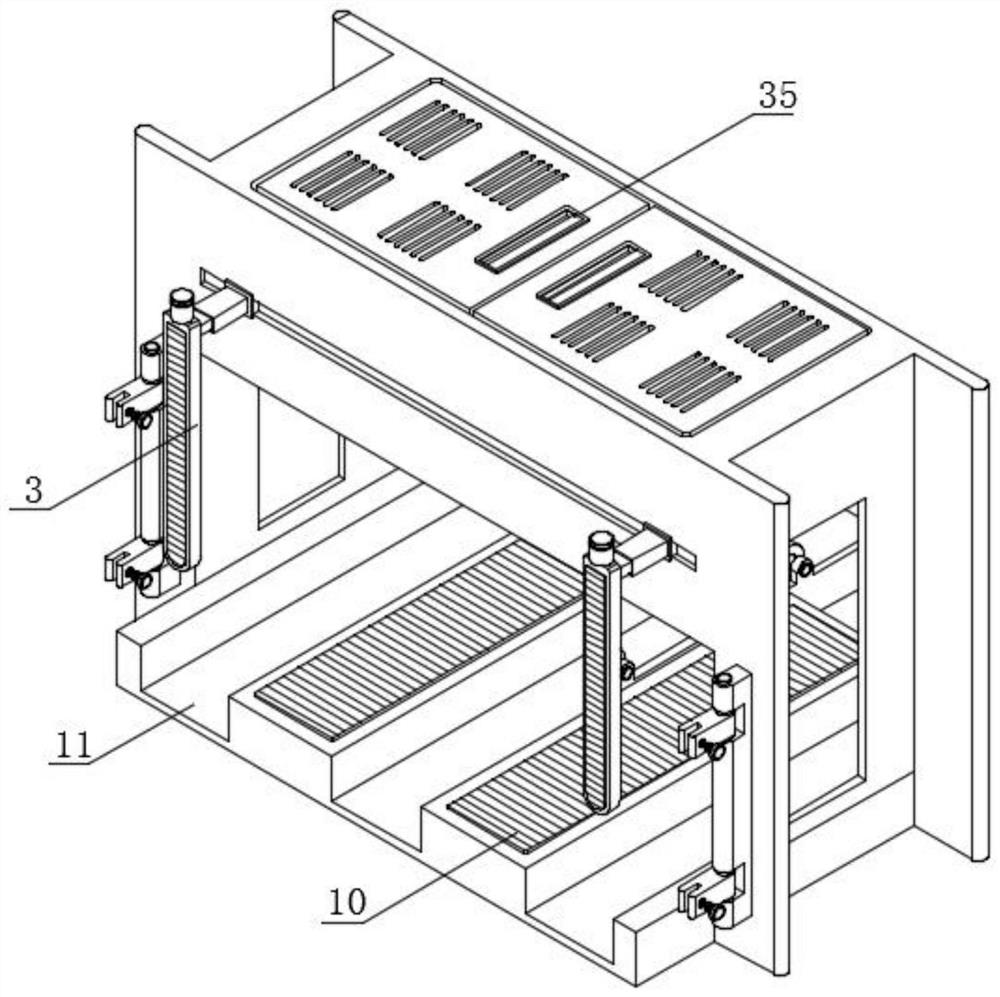

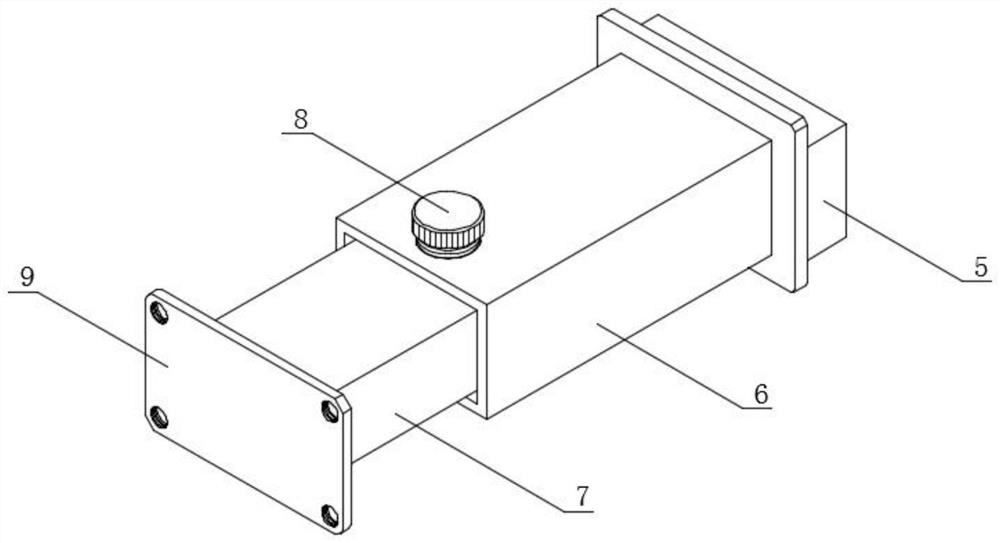

[0042] see figure 1 and image 3 , an embodiment provided by the present invention: a cold press for technological veneer production that can be easily stacked and aligned veneer, including a cold press body 1, a load-bearing platform 2 and a fixed vertical plate 3, and the bottom of the cold press body 1 is installed There is a load-bearing platform 2, and the front end of the top surface of the cold press body 1 is provided with a fixed vertical plate 3, and the number of fixed vertical plates 3 is four; the middle of the surface and the top of the back of the cold press body 1 is provided with a limit slide rail 4 , the interior of the limit slide rail 4 is slidably connected to the limit slider 5; the surface of the limit slider 5 is mounted with a fixed sleeve 6, and the inside of the fixed sleeve 6 is slidably connected with an adjustment plate 7, and the adjustment plate 7 is connected with the fixed sleeve The intersection of the cylinder 6 is threadedly connected wit...

Embodiment 2

[0045] see Image 6 and Figure 8 , an embodiment provided by the present invention: a cold press for the production of scientific and technological veneers that can facilitate stacking and aligning veneers, including a fixed frame 12 and a transmission roller 15, the top of the bearing platform 2 is provided with anti-skid threads 10, A movable slot 11 is opened on the top, a fixed frame 12 is arranged inside the movable slot 11, and the number of the fixed frames 12 is three groups. , a transmission roller 15 is arranged inside the fixed tooth 14, and a rotating shaft is provided at the intersection of the fixed tooth 14 and the transmission roller 15;

[0046] Through the setting of the fixed frame 12 and the transmission roller 15, when the staff needs to assist the veneer feeding, the setting of the movable groove 11 can limit the position of the fixed frame 12, the fixed frame 12, the feeding frame 13, the fixed card The matching work of the teeth 14 and the transmissi...

Embodiment 3

[0048] see figure 2 and Figure 5 , an embodiment provided by the present invention: a cold press for the production of scientific and technological veneers that can facilitate stacking and aligning the veneer, including a protective plate 19, and a fixed seat 16 is installed on both sides of the surface of the cold press body 1. The fixed seat 16 There is a steering tooth 17 connected inside, and a damping shaft is provided at the intersection of the fixed seat 16 and the steering tooth 17, a splint 18 is installed on the top of the steering tooth 17, the surface of the splint 18 is provided with threaded holes, and the interior of the splint 18 is provided with a protection plate 19, and the intersection of the splint 18 and the protective plate 19 is screwed with connecting bolts 20 through threaded holes, and the surface of the protective plate 19 is provided with sound-absorbing cotton 21;

[0049] Through the setting of the protective plate 19, when the staff needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com