Manufacturing method of copper foil die cutting piece

A production method and technology of die-cutting parts, which are applied in chemical instruments and methods, lamination auxiliary operations, lamination devices, etc., can solve the problem of copper foil knife marks, misalignment of protective film edges and copper foil gaps, and unsatisfactory products. Customer requirements and other issues to achieve the effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

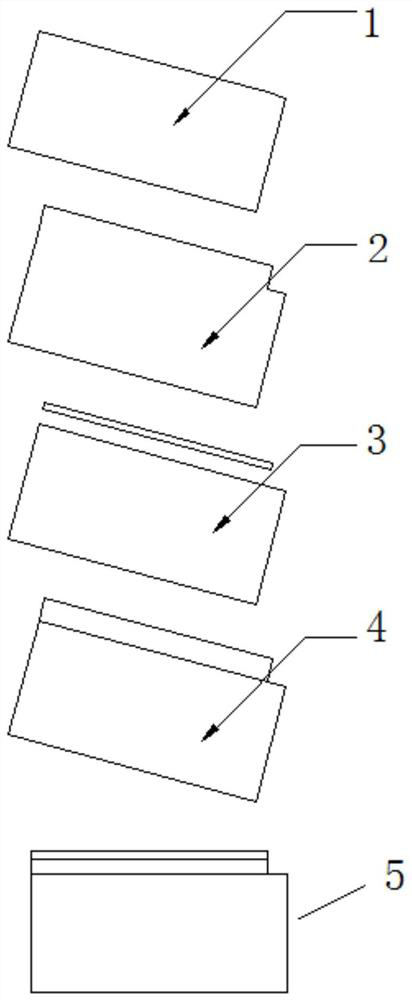

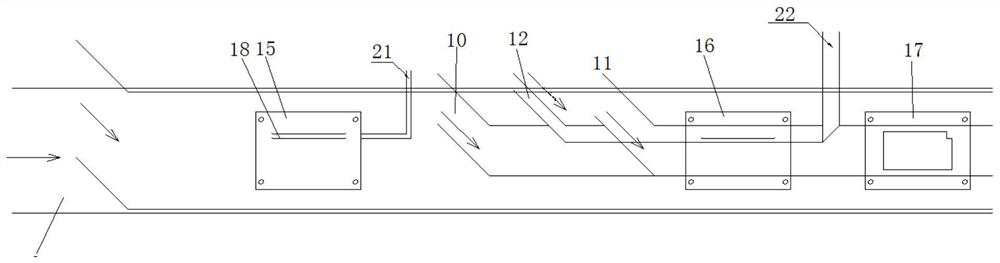

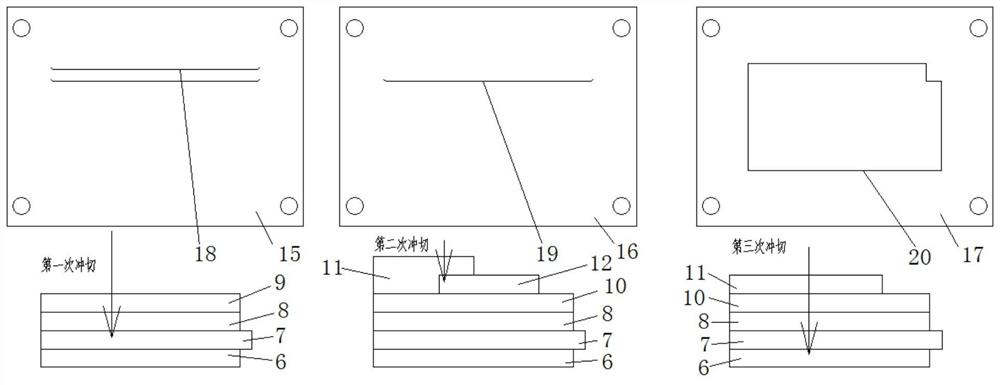

[0031] A kind of manufacturing method of copper foil die-cut piece, such as figure 1 As shown, the copper foil die-cut piece processed in this embodiment includes a protective film layer 1, a copper foil layer 2, a double-sided adhesive layer 3 and a release paper layer 4 arranged in sequence from top to bottom, wherein the release paper layer 4. The outer contours of the double-sided adhesive layer 3 and the copper foil layer 2 overlap, and they are all rectangular shapes with missing corners, which are formed by splicing two rectangles; the protective film layer 1 is rectangular, and is attached to the copper foil layer 2 The surface of the surface is exactly the same as one of the rectangular shapes of the copper foil layer 2, that is, the protective film layer 1 is a rectangle whose three sides coincide with the outline of the copper foil layer 2; the protective film sheet 11 is an insulating single-sided adhesive, and the insulating sheet The adhesive surface of the adhes...

Embodiment 2

[0037] A kind of manufacturing method of copper foil die-cut piece, such as figure 1As shown, the copper foil die-cut piece processed in this embodiment includes a protective film layer 1, a copper foil layer 2, a double-sided adhesive layer 3 and a release paper layer 4 arranged in sequence from top to bottom, wherein the release paper layer 4. The outer contours of the double-sided adhesive layer 3 and the copper foil layer 2 overlap, and they are all rectangular shapes with missing corners, which are formed by splicing two rectangles; the protective film layer 1 is rectangular, and is attached to the copper foil layer 2 The surface of the surface is exactly the same as one of the rectangular shapes of the copper foil layer 2, that is, the protective film layer 1 is a rectangle whose three sides coincide with the outline of the copper foil layer 2; the protective film sheet 11 is an insulating single-sided adhesive, and the insulating sheet The adhesive surface of the adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap