Graphene film etching device

A graphene film and etching device technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve problems such as affecting etching efficiency and etching quality, affecting film production efficiency, and less exchange of solutions, etc. Solve the effect of poor etching effect, eliminate the accumulation of bubbles, and reduce the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

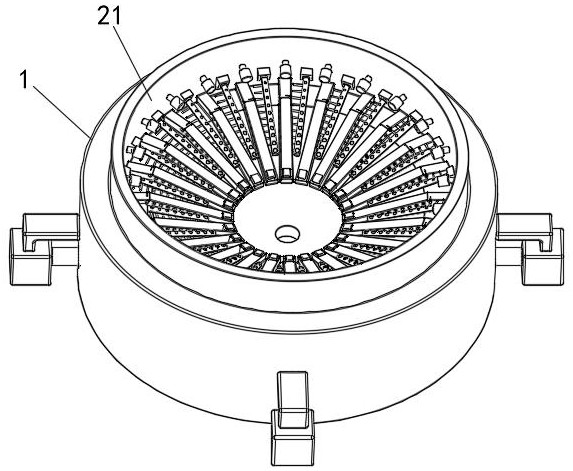

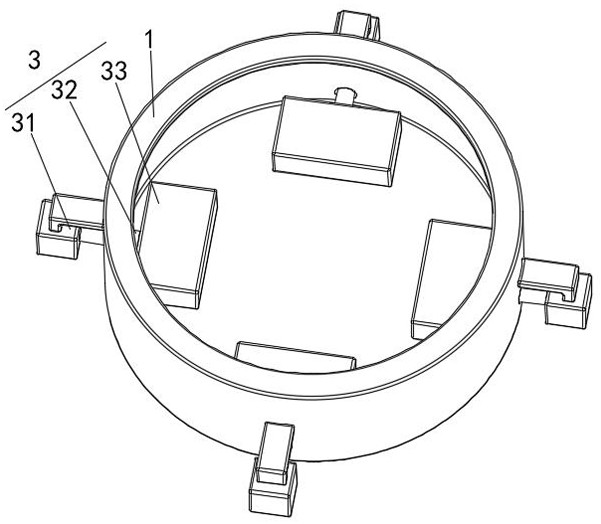

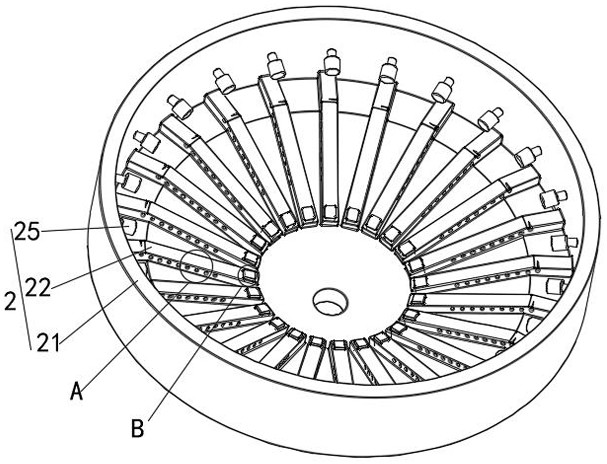

[0042] See Figure 1-9 A graphene film etching apparatus, including the outer casing 1, the etching apparatus 2, and the control device 3, and the axial inner side wall of the outer casing 1 fixes the etching apparatus 2, and the control device 3 penetrates the shaft of the outer casing 1. Inside the side wall and extends into the inside of the outer casing 1, the control device 3 has four adjacent to the axial orientation of the outer casing 1;

[0043] The structure of the etching apparatus 2 includes a etch disc 21, a long strip groove 22, a through hole 23, a photosensitive resistor 24, an irradiation lamp 25, and a promoting device 26, and the etch disk 21 is fixed to the axial inside of the outer casing 1. The strip 22 is opened in the inner bottom surface of the etching disc 21, and the graphene film has risen through the rise in the liquid surface, and since the long strip 22 is opened, the bubbles generated by the injection of the etch can be formed by adjacent long strips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com