Microelectrode structure preparation device and method based on electrofluid reduction drop printing

A technology for preparing devices and microelectrodes, which is applied in the field of additive manufacturing, can solve problems such as complex process, low material utilization rate, and increased material consumption, and achieve the effects of increasing specific surface area, high degree of automation, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

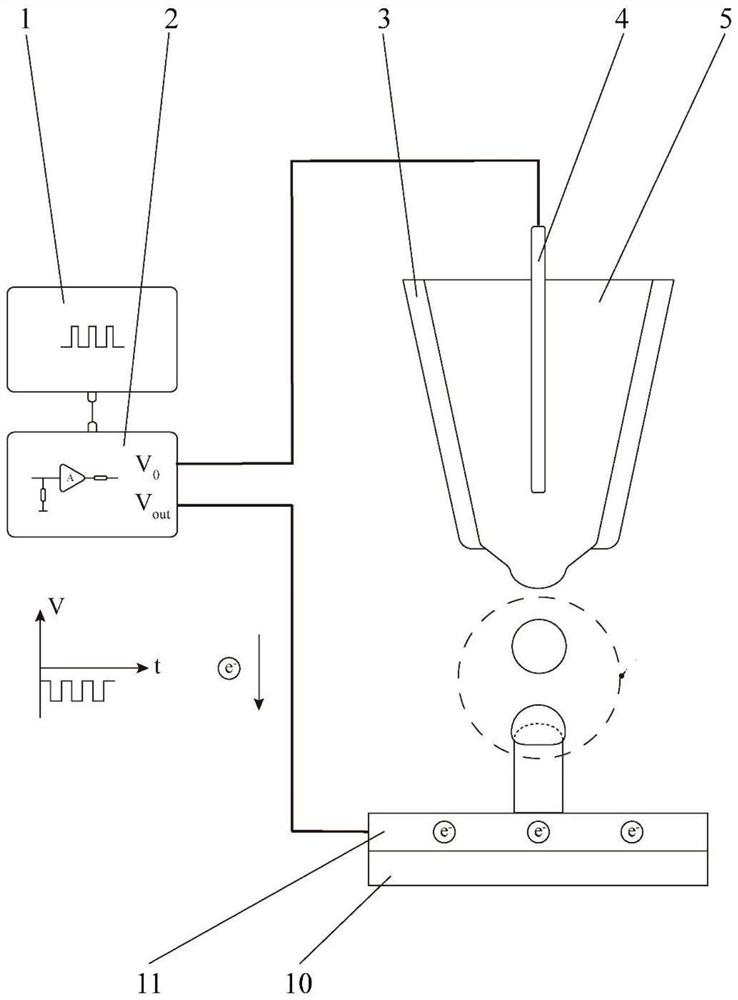

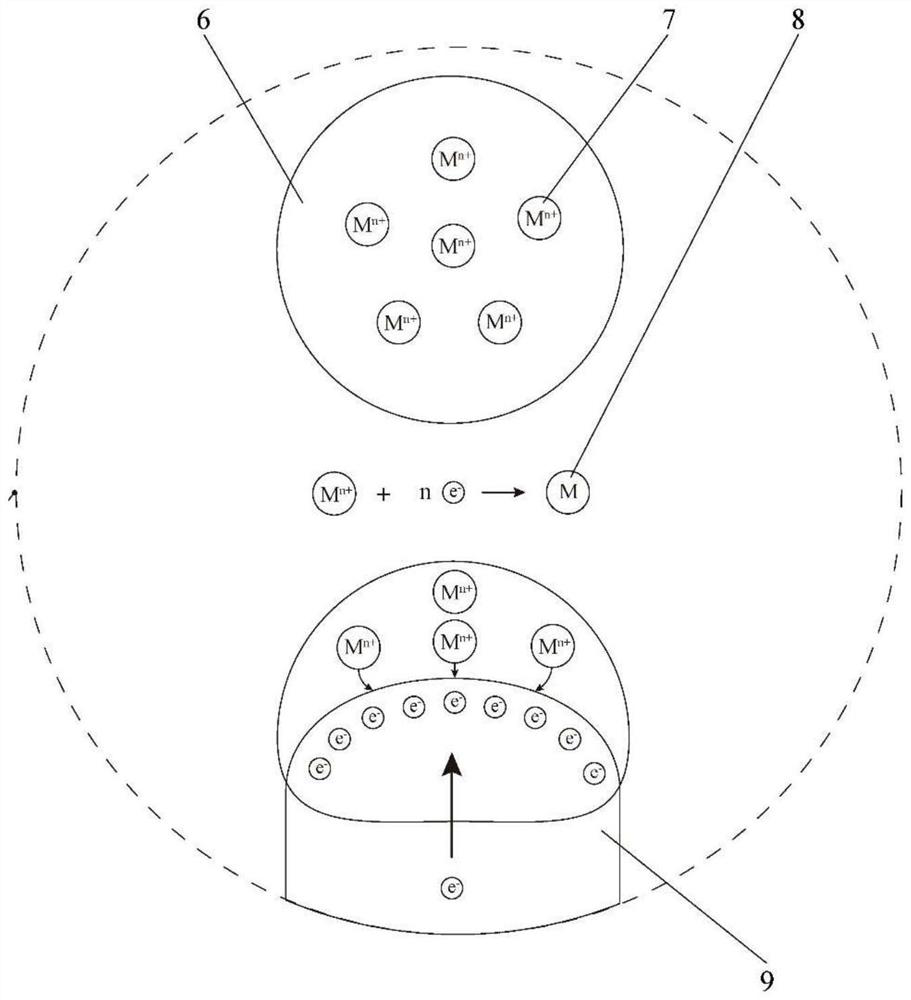

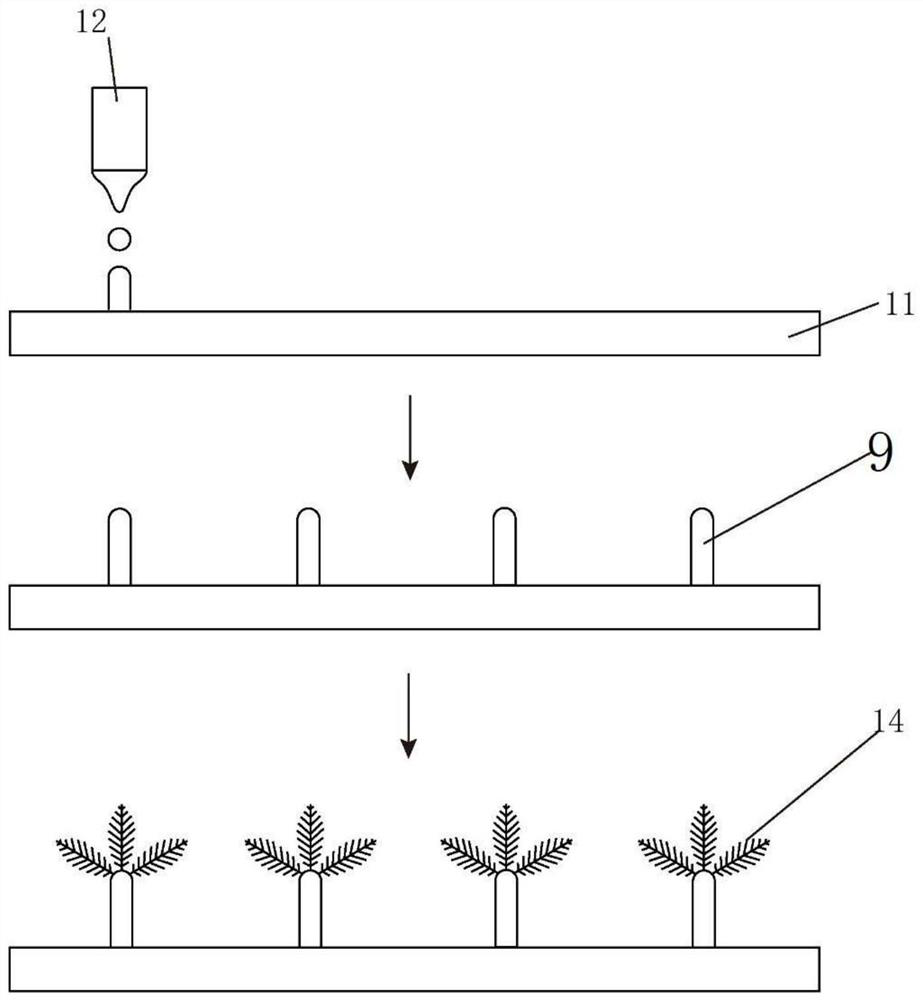

[0028] The present invention is based on the structural design of electrofluid reduction drop printing, a micro-electrode structure preparation device based on electrofluid reduction drop printing, including a high-voltage output device, a glass nozzle 3 and a printing mobile platform 10, the lower end of the glass nozzle 3 is provided with a spout, glass The nozzle 3 is provided with a metal salt solution 5, and the reference terminal V of the high-voltage output device 0 Connected with a conductive wire 4, the conductive wire 4 is set in the metal salt solution 5 in the glass nozzle 3, a conductive base 11 is fixed on the printing mobile platform 10, and the conductive base 11 is connected to the high-voltage output terminal V of the high-voltage output device. out connection, the high voltage output device is used to provide a negative pulse waveform.

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com