Continuous production device for producing modified asphalt with ultrahigh viscosity and toughness

A modified asphalt and production device technology, applied in the field of asphalt production, can solve the problems of inability to realize efficient mixing and processing of asphalt, increasing demand for modified asphalt, affecting production efficiency, etc. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

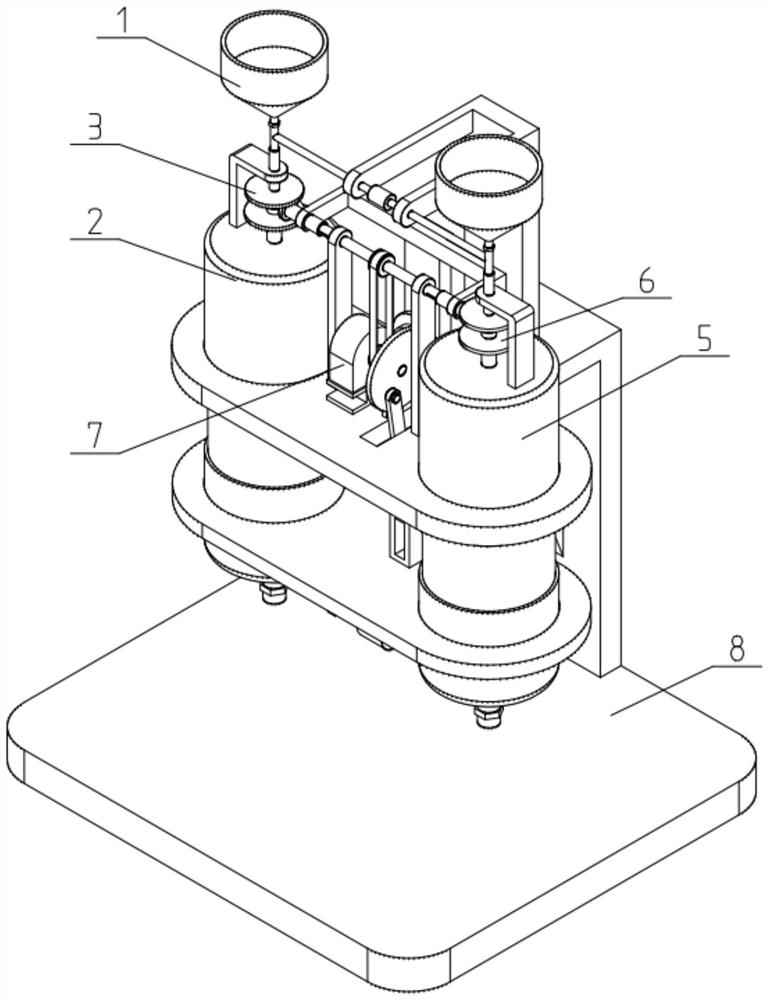

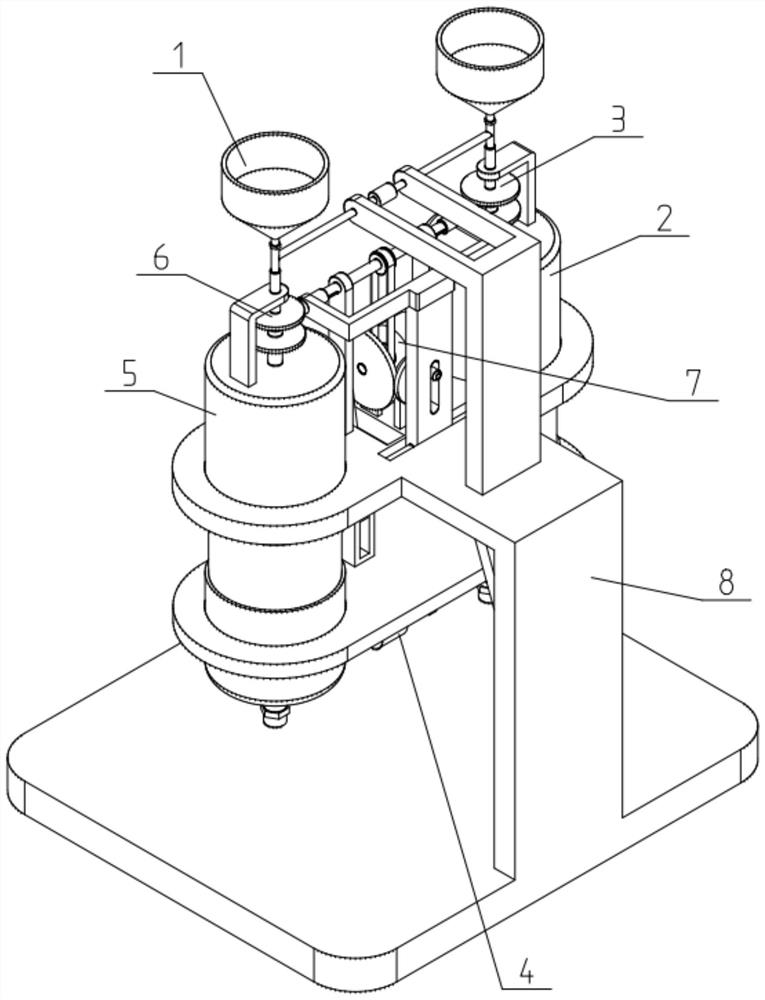

[0039] Such as Figure 1-12 As shown, a continuous production device for ultra-high viscosity and toughness modified asphalt production, including a feeding mechanism 1, a first reaction tank 2, a mixing mechanism 3, a feeding mechanism 4, a second reaction tank 5, and a shearing mechanism 6. The driving mechanism 7 and the stand 8; one end of the feeding mechanism 1 installed on the stand 8 is connected to the mixing mechanism 3, so as to guide the raw materials into the first reaction tank 2 through the mixing mechanism 3; The other end of mechanism 1 is connected with shearing mechanism 6, to guide raw material in the first reaction tank 2 by shearing mechanism 6; Material delivery mechanism 4 is connected with first reaction tank 2 and second reaction tank 5, to The raw materials are pumped into the second reaction tank 5 through the first reaction tank 2; a mixing mechanism 3 is installed in the first reaction tank 2 to mix and stir the raw materials in the first reaction...

Embodiment 2

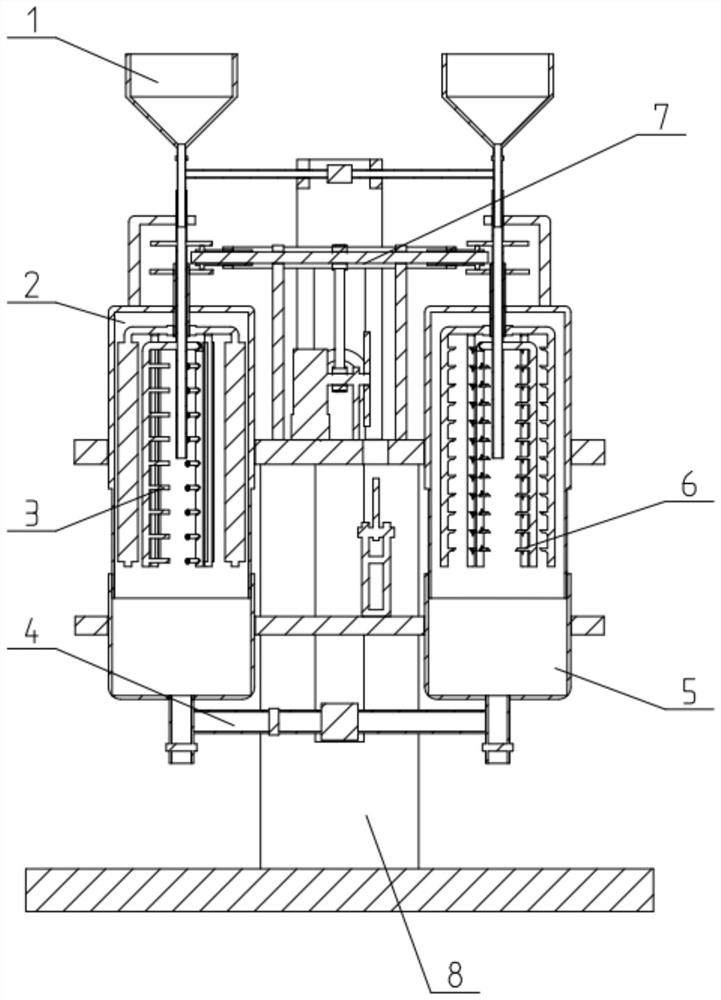

[0042] Such as Figure 1-12 As shown, the mixing mechanism 3 includes a first friction wheel 31, a second friction wheel 32, a first outer tube 33, a first inner tube 34, an inner stirring rod 35 and an outer stirring rod 36; the first friction wheel 31 is fixed On the first outer tube 33, the middle part of the first outer tube 33 is sealed and rotated on the top surface of the first reaction tank 2, and the second friction wheel 32 is fixed on the first inner tube 34, and the middle part of the first inner tube 34 is sealed and rotated at the second Inside an outer tube 33; the first outer tube 33 is positioned on the tube body of the first reaction tank 2 and surrounds and fixes a plurality of outer stirring rods 36; The stirring rod 35, the inner stirring rod 35 is located inside the outer stirring rod 36; the driving mechanism 7 is connected to the first friction wheel 31 and the second friction wheel 32; A stirring impeller is fixed on it.

[0043] After the drive mech...

Embodiment 3

[0047] Such as Figure 1-12 As shown, the feed mechanism 1 includes a feed hopper 11, a feed pipe 12 with a control valve and a horizontal feed pipe 13 with a pump; the feed hopper 11 and the feed pipe 12 are respectively provided with two, The two feeding hoppers 11 are fixedly connected with the two feeding pipes 12 one by one, and the two feeding pipes 12 are fixedly connected by a horizontal feeding pipe 13, which is located below the control valve; the horizontal feeding pipe 13 passes through the bracket It is fixed on the stand 8; one feeding tube 12 is sealed and moved in the first inner tube 34, and the other feeding tube 12 is sealed and moved in the second inner tube 64. When the feeding mechanism 1 is in use, the two feeding hoppers 11 can be used to feed materials respectively. When the asphalt mixture circulation process is required, the control valves of the two feeding pipes 12 are closed, and the horizontal feeding pipe 13 is turned off. The pump is turned on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com