Method for producing layered body in multi-component method

A layered, multi-component technology, used in devices, coatings, instruments, etc. for applying liquid to surfaces, and can solve problems such as poor heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

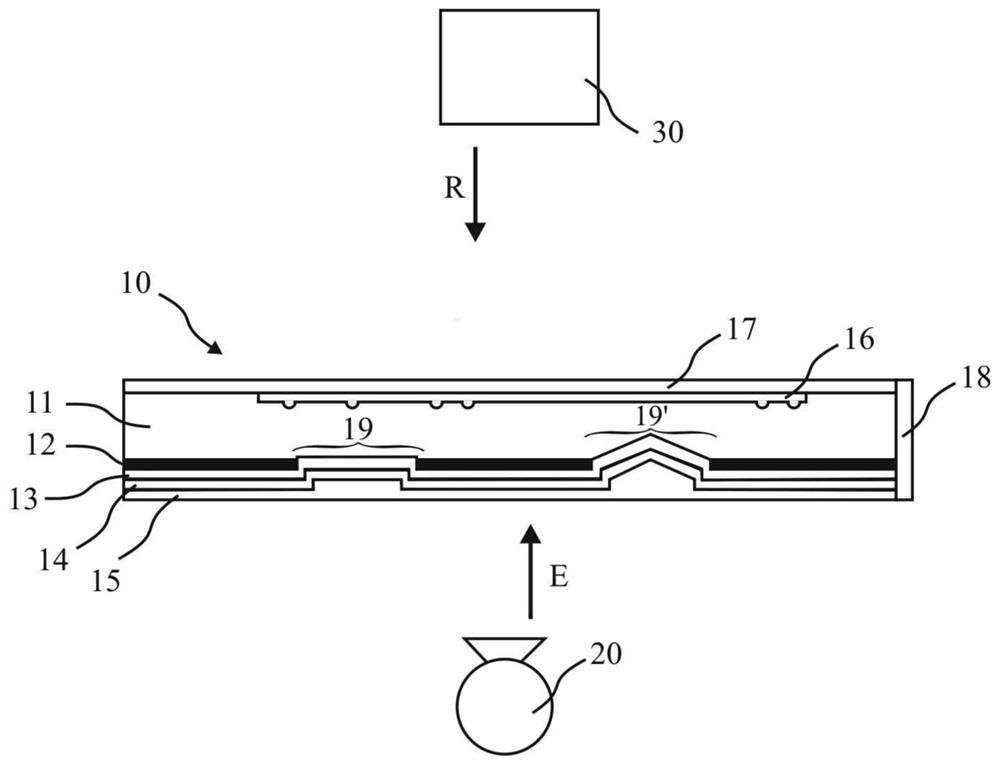

[0036] figure 1 A sectional view of a layered body 10 is shown, which is produced in a multi-component method and is used as a radome. The radome 10 may serve as an exterior covering member of the vehicle and cover a radar sensor 20 provided inside the vehicle. Radar sensor 20 arranged behind radome 10 cannot be seen from the outside of the vehicle.

[0037] The radome 10 has a base 11 . A resin layer 17 is applied to the surface of the substrate 11 facing away from the radar sensor 20 . A heating film 16 is arranged at least partially between the resin layer 17 and the substrate 11 . The outer surface of the resin layer 17 and thus the outer surface of the radome 10 can be tempered, in particular heated, by means of the heating film 16 in order to melt away deposits such as rainwater, ice or snow. Furthermore, the heating film can be controlled in such a way that a temperature is induced in the resin layer 17 at which a self-healing process is triggered by which damages, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com