Hybrid flow shop scheduling optimization method

A technology for workshop scheduling and optimization methods, applied in the direction of control/regulation systems, instruments, and comprehensive factory control, etc., can solve problems such as difficulties, and achieve the effects of improving production efficiency, ensuring search capabilities, and improving search efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The invention will be further described below with reference to the accompanying drawings and examples.

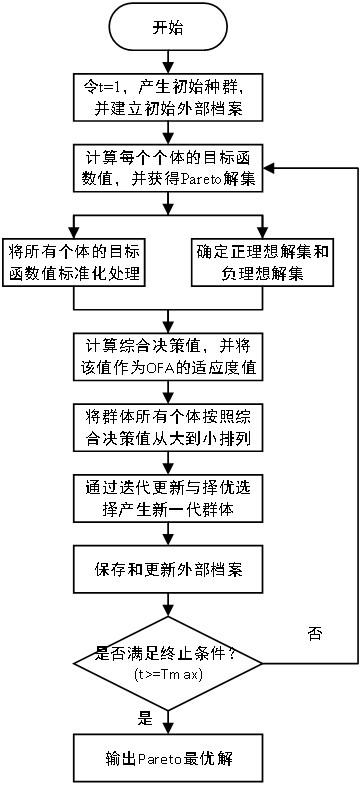

[0077] Please refer to figure 1 The present invention provides a figure 1 As shown, this embodiment provides a method of dispatching optimization of a mixed water workshop, specifically comprising the steps of:

[0078] Step S1: Description of the symbols of the production scheduling problem between multi-target water workshops;

[0079] Step S2: Establish constraints must be met during production optimization;

[0080] Step S3: Determine the target to be optimized, establish a corresponding multi-objective optimization function;

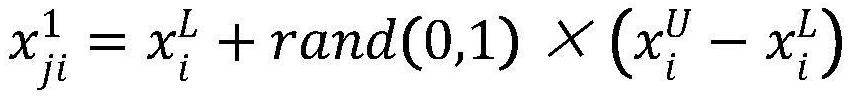

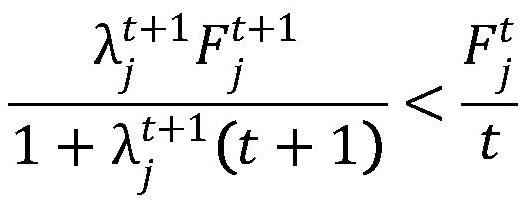

[0081] Step S4: Design Based on the Multi-Objective Best Food Algorithm (Optimal Foraging Algorithm, Optimal Foraging Algorithm, OFA Algorithm);

[0082] Step S5: Perform iterative optimization operation, output Pareto optimal solution;

[0083] Step S6: Obtain the best schedule according to the optimization result of step S5.

[0084] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com