Crack detection method, electronic equipment and readable storage medium

A crack detection and crack technology, applied in the field of detection, can solve problems such as low crack detection accuracy, and achieve the effect of improving crack detection efficiency, improving accuracy, and accurate crack detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

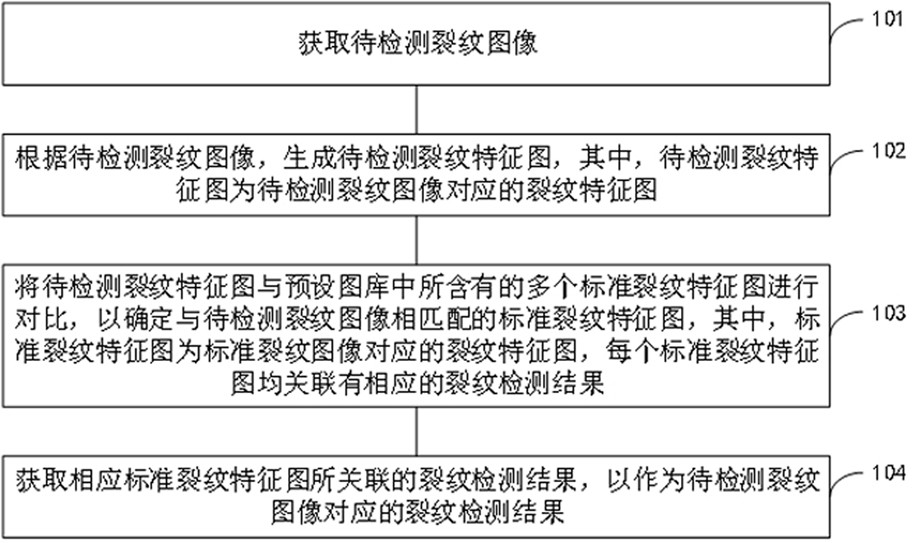

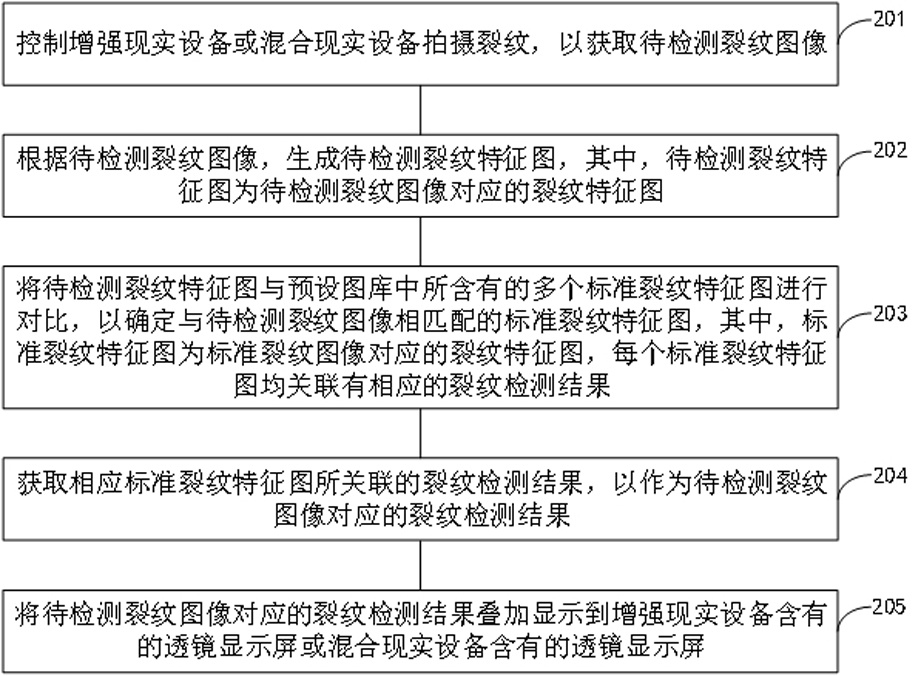

[0052] Connection with the above two embodiments, see figure 2 , Crack detection method, comprising:

[0053] S201, the control device augmented reality or mixed reality device shooting crack crack to be detected to obtain an image;

[0054] S202, a crack to be detected according to the image, wherein FIG generating cracks to be detected, wherein the feature to be detected crack crack graph corresponding to the image to be detected FIG crack characteristics;

[0055] S203, to be more standard features of FIG crack crack FIG characterized preset library contained detected by comparing a standard to determine the crack to be detected, wherein FIG crack matched image, wherein the standard characteristic graph crack crack standard image FIG crack corresponding features, wherein each standard FIG cracks are associated with respective crack detection result;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com